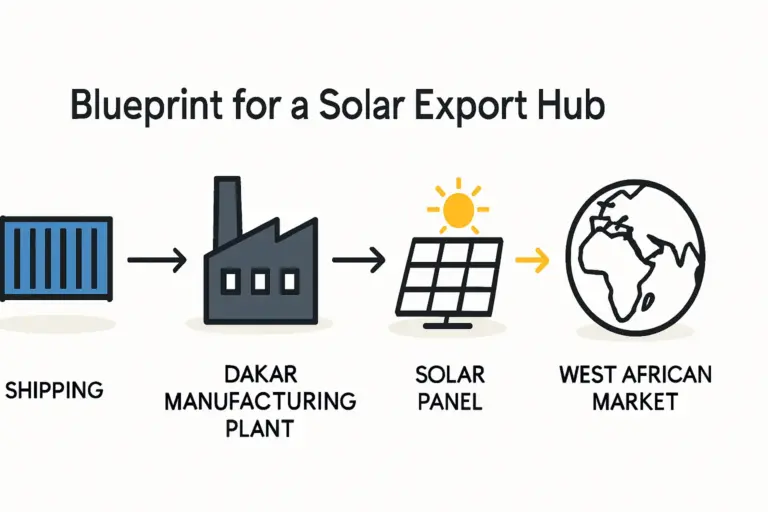

An investor identifies a promising location for a new solar module factory in Senegal, miles from the congested capital of Dakar. The land is affordable, labor is available, and government incentives under the ‘Plan Sénégal Émergent’ (PSE) encourage such decentralized industrial growth. The initial business plan looks solid, but a critical question soon arises: can the local infrastructure support a high-tech manufacturing operation that runs around the clock?

This scenario is common for entrepreneurs in many fast-growing economies. While the ambition is to build modern industrial capacity, the reality of utility infrastructure outside major metropolitan areas can present significant challenges. For a solar module factory, where precision and consistency are paramount, a stable supply of electricity and clean water is not just a convenience—it is fundamental to operational viability.

Here, we outline the core challenges of securing power and water for solar factories in developing regions and explore strategic solutions that can transform these potential liabilities into operational strengths.

The Hidden Costs of Unreliable Utilities in Solar Manufacturing

Unlike a simple warehouse or assembly plant, a solar module factory relies on sensitive, automated equipment that reacts poorly to utility fluctuations. The consequences of an unstable grid or inconsistent water supply extend far beyond mere inconvenience.

The Challenge of Electricity Supply

In many regions, the national grid is not yet equipped to provide the high-quality power that industrial manufacturing requires. In Senegal, for instance, while national electricity access is around 70%, this figure drops to approximately 40% in rural areas. Businesses operating in these locations often face:

-

Frequent Power Outages: Load shedding and unplanned blackouts can halt production lines, resulting in wasted materials, missed deadlines, and significant financial losses.

-

Grid Instability: Voltage drops and power surges can damage sensitive electronic components within the solar panel manufacturing machines, leading to costly repairs and extended downtime.

-

High Costs: Even when the grid is available, industrial electricity tariffs can be high. In Senegal, costs can reach $0.25 per kilowatt-hour, a substantial operational expense that directly impacts profitability.

The Importance of Water Quality

Water plays a critical role in two key factory processes: cleaning solar glass before lamination and cooling machinery. This makes the reliability and quality of the water supply essential.

Outside major cities, municipal water can be inconsistent. It may contain high concentrations of minerals like calcium and magnesium, often called ‘hard water.’ Using this untreated water can lead to:

-

Reduced Module Quality: Mineral deposits left on the glass after washing can create defects during lamination, affecting the final product’s efficiency and longevity.

-

Equipment Damage: Scale buildup inside cooling systems can cause overheating and mechanical failure.

-

Supply Interruptions: Depending on a single municipal source without on-site storage creates a vulnerability if the local supply is cut off.

A Strategic Approach to Power Independence

Instead of viewing weak grid infrastructure as an insurmountable obstacle, a successful business plan incorporates on-site power generation and management from the start. The most resilient and cost-effective approach is a hybrid power system.

The Three Pillars of a Resilient Power System

A hybrid system combines multiple power sources to ensure a continuous, stable, and high-quality electricity supply, independent of grid performance.

-

On-site Solar Generation: A solar factory has a unique advantage: it can use the very product it creates to power its own operations. A dedicated solar PV array, installed on the factory roof or adjacent land, can generate a significant portion of the facility’s electricity during daylight hours, drastically reducing reliance on an expensive grid.

-

Battery Energy Storage System (BESS): Batteries form the core of a stable power supply. They store excess solar energy generated during the day for use at night or during grid outages. A BESS also acts as a crucial buffer, absorbing voltage spikes and filling momentary dips to provide clean, uninterrupted power to sensitive machinery.

-

Backup Generator: A diesel generator serves as the final layer of security. While not intended for continuous operation due to high fuel and maintenance costs, it ensures the factory can run through prolonged grid outages or periods of exceptionally high demand.

This integrated system is not an expense, but a strategic investment in production continuity and long-term cost control.

Ensuring Water Quality and Availability

Just as with power, the solution to water challenges lies in establishing on-site independence. This involves treating and storing water to meet the specific demands of the manufacturing process.

On-Site Water Treatment: The Non-Negotiable

The industry standard for achieving the necessary water purity is a commercial Reverse Osmosis (RO) system. An RO system uses a series of filters and a semi-permeable membrane to remove dissolved minerals, salts, and other impurities.

By processing all incoming water—whether from a municipal connection or a borehole—an RO system ensures that the water used for cleaning glass and cooling equipment is consistently pure. This prevents defects and protects machinery, making such systems a key part of the overall solar module factory building requirements.

Combined with on-site storage tanks, this approach gives the factory a reliable supply of high-quality water, insulating it from external supply issues.

Frequently Asked Questions (FAQ)

Can the factory’s own solar panels power its operations?

Yes. A properly sized solar array can cover a significant portion, if not all, of the factory’s daytime electricity consumption. When combined with a battery storage system, it can enable near-complete energy independence and drastically lower operational costs.

Is a standalone diesel generator a sufficient solution?

While simple to install, relying solely on a diesel generator is not a viable long-term strategy. The high and volatile cost of diesel fuel, constant maintenance needs, and environmental impact make it an expensive and unreliable primary power source for continuous manufacturing. It is best used for backup purposes only.

What is the real cost of production downtime?

The cost of downtime extends beyond the immediate loss of output. It includes idle labor costs, potential damage to materials mid-process, and reputational harm from failing to meet delivery schedules. A single day of lost production can easily cost more than the investment in preventative measures.

How much planning is required for these systems?

Power and water infrastructure should be designed from the very beginning, during the initial feasibility and planning stages. Retrofitting these systems into an existing facility is far more complex and expensive. Experience in turnkey projects shows that integrating power and water solutions from day one is the most efficient and cost-effective approach.

Conclusion: From Infrastructure Liability to Strategic Asset

For entrepreneurs looking to build solar factories in emerging markets, utility infrastructure does not have to be a barrier. By planning for energy and water independence from the outset, a business can turn a regional challenge into a powerful competitive advantage.

A hybrid power system combined with on-site water treatment creates a resilient, self-sufficient manufacturing environment. This approach ensures consistent production quality, protects valuable equipment, and provides long-term control over critical operational costs. Understanding these foundational requirements is a critical first step for anyone exploring how to start a solar module production business. This level of preparedness is the mark of a forward-thinking and ultimately successful industrial project.