Integrating with Swiss R&D: A Strategic Advantage for New Solar Manufacturers

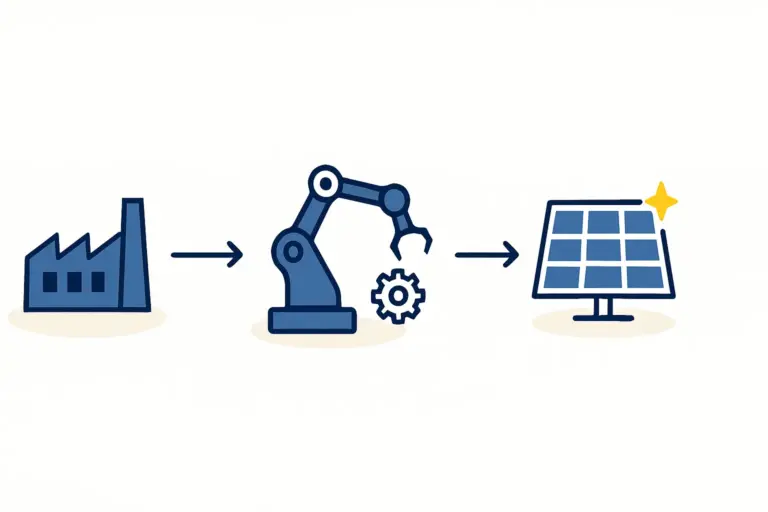

An entrepreneur planning to enter the solar manufacturing sector often focuses on the immediate essentials: securing a location, sourcing machinery, and establishing a production line. The conventional approach involves purchasing a turnkey solution to begin assembly as quickly as possible.

Yet a more strategic path exists—one that builds a lasting competitive advantage from the very beginning. This path means collaborating with world-class research and development (R&D) institutions.

For entrepreneurs aiming to produce technologically superior products, not just standard solar modules, partnering with Switzerland’s globally recognized research centers offers a distinct and powerful advantage. This article explores how such a collaboration can transform a new manufacturing venture into a technology leader.

Why Switzerland? The Foundation of a Global Technology Leader

For over a decade, Switzerland has consistently ranked number one in the World Intellectual Property Organization’s Global Innovation Index. This distinction is no accident. The country’s success is built on a foundation of significant investment in R&D, a culture of precision engineering, and an ecosystem that excels at transforming scientific breakthroughs into commercial applications.

For the solar industry, two institutions are particularly noteworthy:

-

EPFL (École Polytechnique Fédérale de Lausanne): A university renowned for its fundamental research in photovoltaics, particularly in developing next-generation solar cells like perovskite-silicon tandems, which have set world records for efficiency.

-

CSEM (Centre Suisse d’Électronique et de Microtechnique): An applied research and technology organization that specializes in bridging the gap between laboratory discovery and industrial production. CSEM helps companies scale and integrate cutting-edge technologies into reliable, manufacturable products.

Engaging with this ecosystem allows a new manufacturer to move beyond the limitations of standard equipment and build a business on superior technology—a critical factor for long-term viability and profitability. While understanding the investment requirements for a solar factory is a crucial first step, allocating a portion of that investment to R&D can yield substantial returns.

The Tangible Benefits of Collaborating with Swiss Research Institutions

Partnering with a Swiss R&D institution is not merely a matter of prestige; it delivers concrete business advantages that are difficult to replicate.

Access to Cutting-Edge Photovoltaic Technologies

The commercial solar market often lags several years behind the innovations developed in research labs. By collaborating with institutions like EPFL or CSEM, a manufacturer gains access to technologies before they become mainstream. This could include:

-

Higher-Efficiency Cell Architectures: Moving beyond standard PERC to more advanced concepts like TOPCon or Heterojunction (HJT).

-

Novel Module Designs: Developing modules optimized for specific climates, such as high-temperature or low-light conditions, which are common in many emerging markets.

-

Advanced Materials: Incorporating new materials for backsheets, encapsulants, or coatings that improve module longevity and performance.

The ‘technology transfer’ process managed by these institutions ensures that these advanced concepts are adapted for viable mass production. A deeper understanding of these different solar cell technologies is fundamental to making an informed decision.

A World-Class Engineering Talent Pool

Swiss institutions attract top engineering talent from around the globe. A collaboration provides a direct channel to this pool of expertise. PhD candidates and senior researchers can be engaged to solve specific, complex production challenges that a new in-house team may not be equipped to handle. This access to specialized knowledge accelerates problem-solving and reduces the costly trial-and-error phase of launching new products.

De-Risking Technological Investments

Production machinery represents a major capital expenditure for any new solar plant, and investing millions in a new technology line that may not perform as expected is a significant risk. R&D partnerships offer a controlled environment to pilot and validate new processes on a smaller scale. This process allows a manufacturer to confirm the viability and potential return on investment before committing to full-scale industrial machinery.

Building a Defensible Competitive Moat

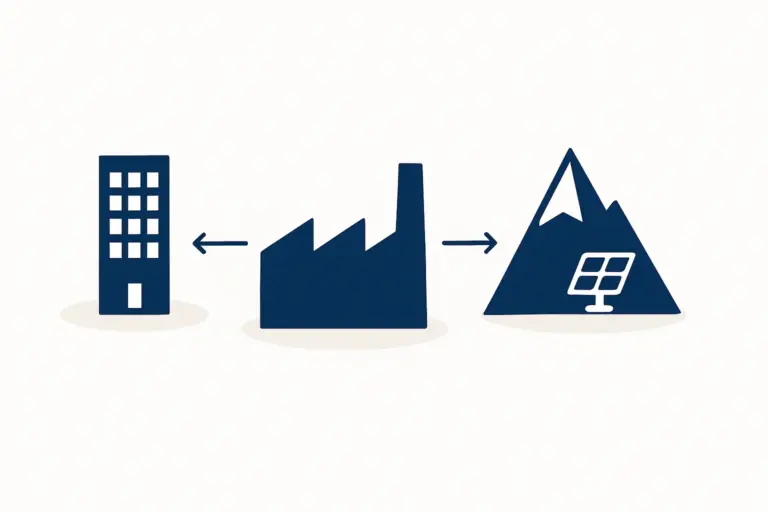

Any competitor can purchase the same off-the-shelf production line. This leads to a market where competition is based primarily on price, eroding profit margins. A collaboration that results in a proprietary process or a unique module design creates a defensible competitive advantage. The intellectual property (IP) developed through such a partnership becomes a valuable company asset, creating a barrier to entry for competitors and justifying a premium price for the product.

How Does a Partnership with Institutions like EPFL or CSEM Work in Practice?

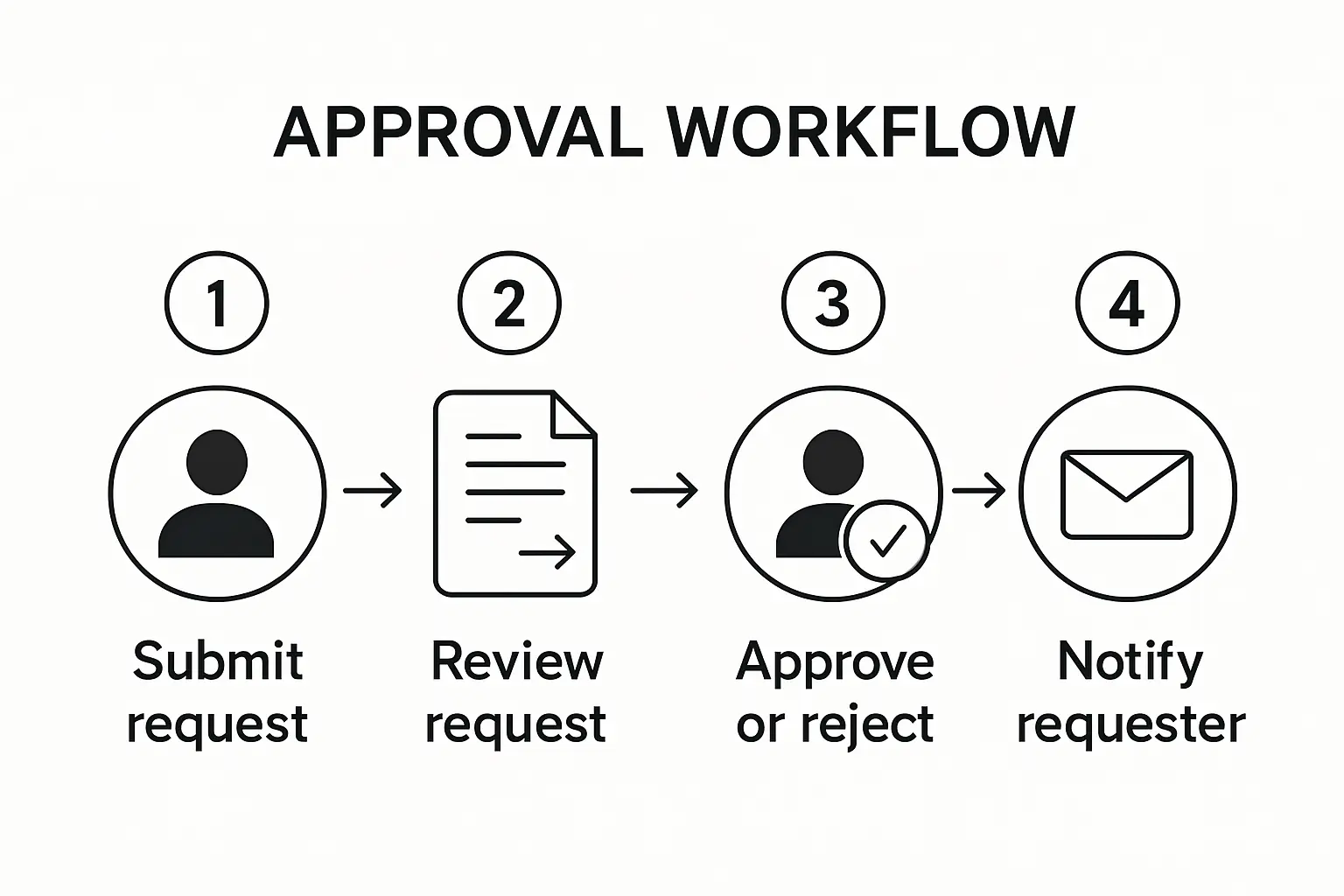

Engaging with a world-class research institution may seem daunting, but the process is structured and well-defined, moving from a broad business objective to a specific, collaborative project.

The Initial Engagement: Defining a Project Scope

A successful collaboration begins with a clear business problem or technological goal. Simply asking for ‘innovation’ isn’t enough; the objective must be specific. For example:

-

‘How can we develop a bifacial solar module that minimizes degradation in the high-humidity and high-UV conditions of West Africa?’

-

‘What is the most cost-effective pathway to increase our module efficiency by 2% within the next 24 months?’

Expert consultants often facilitate this process. They help translate business goals into a technical brief that a research institution can effectively address, ensuring the project is aligned with both commercial needs and scientific capabilities.

Models of Collaboration

Partnerships can take several forms depending on the manufacturer’s goals and resources:

-

Direct Research Contracts: The manufacturer commissions the institution to conduct specific research to solve a defined problem. The scope, deliverables, and timeline are clearly agreed upon.

-

Joint Development Projects: The manufacturer and institution work together, sharing resources and personnel to develop a new technology. This is a more deeply integrated approach.

-

Technology Licensing: The manufacturer acquires the rights to use a technology or patent that the institution has already developed, receiving support to integrate it into its production line.

Navigating the Challenges: What to Consider Before Engaging

A strategic R&D partnership is a significant commitment. Acknowledging the potential challenges is key to a successful outcome.

Bridging the Gap Between Academia and Industry

Academic institutions are typically driven by the pursuit of knowledge and scientific publication, while industrial ventures focus on profitability and market timelines. A successful partnership requires a formal agreement that aligns these different objectives, with clear milestones and commercial goals.

Intellectual Property (IP) Agreements

From the outset, it’s critical to establish who will own any intellectual property resulting from the collaboration. Contracts should clearly define the rights to use, license, or patent new inventions. This prevents future disputes and ensures the manufacturer can capitalize on the innovation it helped fund.

Resource Commitment

This is not a passive investment. The manufacturer must dedicate internal resources—including personnel, time, and funding—to manage the partnership. As one project stakeholder noted after a successful technology transfer project, ‘The initial investment in R&D seemed high, but it paid for itself within three years by giving us a product no competitor could match locally.’

Frequently Asked Questions (FAQ)

Is this type of collaboration only for large, established companies?

No. While large corporations have dedicated R&D departments, small and medium-sized enterprises (SMEs) can also engage effectively. The key is to start with a well-defined, focused project rather than an open-ended research program.

How long does it take to see results from an R&D partnership?

This varies with the project’s complexity. An initial feasibility study might take three to six months. A project to adapt an existing technology could take 12 to 18 months. Developing a completely new technology from the ground up can take several years.

What is the typical cost of such a collaboration?

Costs are entirely project-dependent. A small-scale consulting project or feasibility study might cost tens of thousands of euros. A comprehensive joint development project to bring a new technology to market could require an investment of several hundred thousand to over a million euros, spread over the project’s lifetime.

Do I need a technical team in-house to manage this relationship?

Having at least one technically competent person on your team to act as the primary liaison is highly recommended. For entrepreneurs without a deep technical background, a trusted external consultancy can serve as this vital bridge, ensuring the project stays on track and aligned with business objectives.

The First Step Towards a Technology-Led Future

For the ambitious entrepreneur, starting a solar module factory is about more than just entering a growing market; it’s about establishing a resilient and profitable business for the long term.

While the initial setup of a production line is a crucial step, building a strategic partnership with a world-class R&D institution like those in Switzerland is what separates market followers from market leaders. This approach transforms a manufacturing operation from a mere user of technology into an innovator.

It’s a strategic decision that lays the groundwork for sustained growth, higher margins, and a powerful brand reputation. Ultimately, understanding the full pathway of how to start a solar module factory means looking beyond the factory floor to the sources of future innovation.