An investor glancing at a map of Australia might see a continent of vast, open spaces and assume that finding a suitable factory location would be simple. The reality on the ground, however, is far more complex.

Industrial land in key economic zones is surprisingly scarce, with vacancy rates in cities like Sydney and Melbourne falling below 2%. This single data point reveals a crucial truth: the success of a solar module manufacturing venture in Australia hinges on a decision made long before the first machine is installed—the choice of its location.

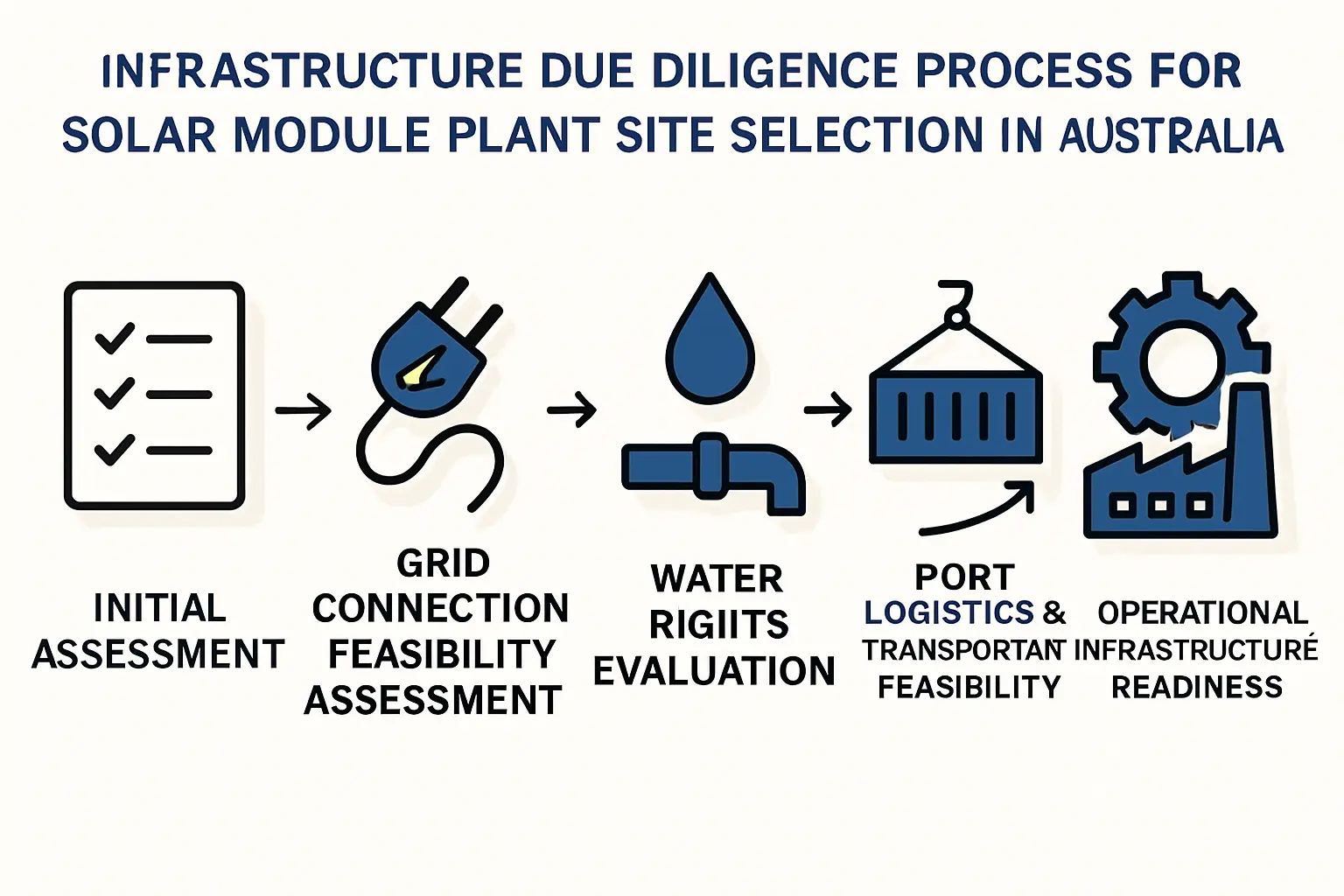

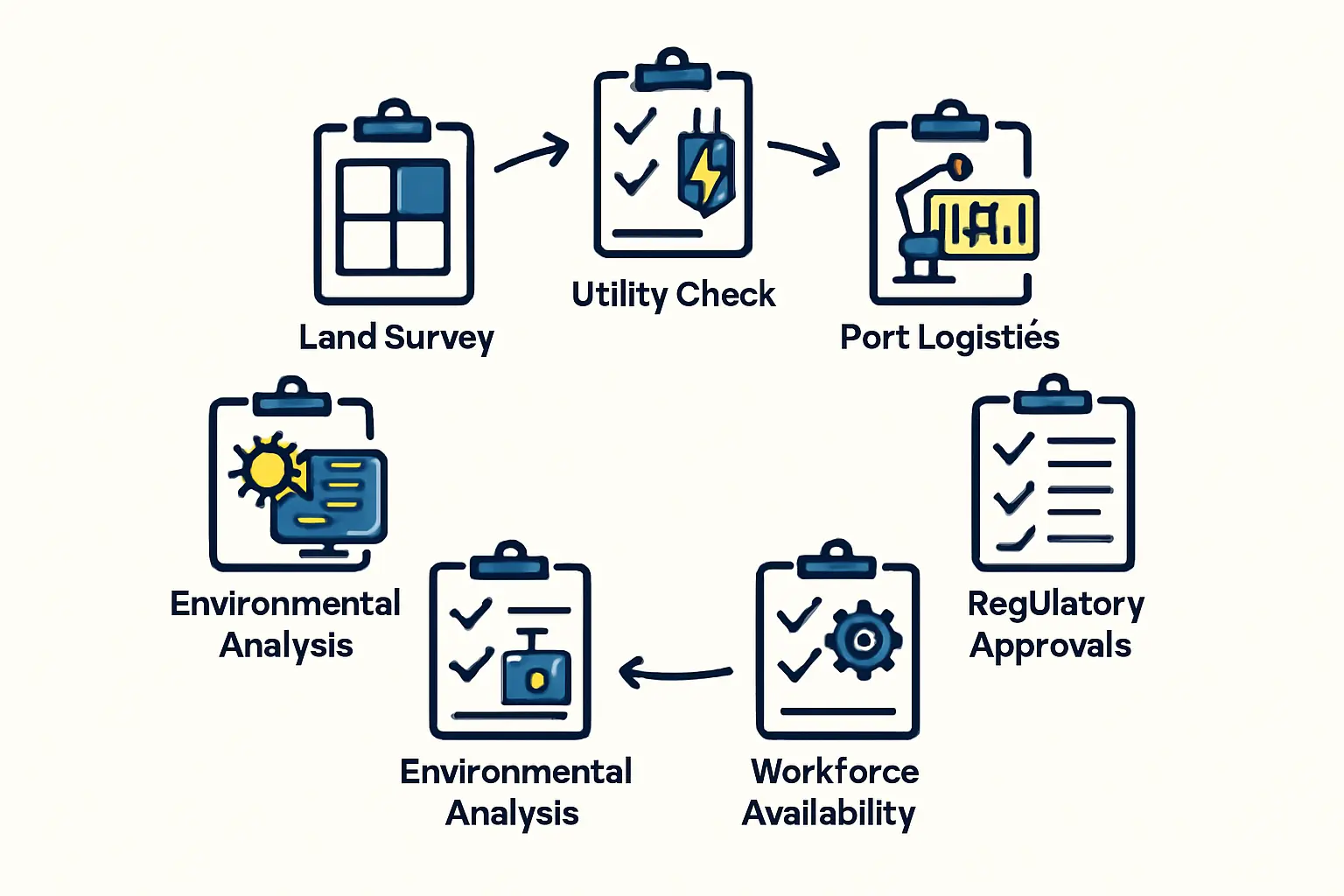

This guide examines the critical infrastructure and site selection factors for establishing a solar module plant in Australia. It offers a foundational understanding of the challenges and opportunities across industrial land, utility access, logistics, and labor, helping entrepreneurs navigate this essential planning stage.

The Foundation: Why Site Selection Determines Long-Term Viability

Choosing a factory site is not merely a real estate transaction; it’s a strategic decision that sets the operational and financial trajectory of the business for decades. An optimal location can lower daily operating costs, streamline the supply chain, and attract skilled personnel.

A poorly chosen site, conversely, can create persistent logistical bottlenecks, inflate utility expenses, and limit access to the right workforce, undermining the plant’s competitiveness before production even begins. A comprehensive site evaluation is an indispensable step in the business planning process, forming the bedrock of a resilient manufacturing operation.

Navigating Australia’s Industrial Real Estate Landscape

While Australia is geographically expansive, its prime industrial land is concentrated around major metropolitan areas and transport corridors. This concentration has led to intense competition for suitable sites, particularly those zoned for industrial use and equipped with the necessary infrastructure.

Recent market data underscores this challenge. Commercial real estate vacancy rates in Australia’s major cities are at historic lows:

- Sydney: 1.1%

- Melbourne: 1.5%

- Perth: 1.8%

- Brisbane: 2.2%

- Adelaide: 3.0%

This scarcity has driven a significant increase in land values. In Western Sydney, a key industrial hub, land values have reportedly risen by as much as 134% since 2019. For new investors, securing a well-positioned parcel of land requires careful planning, a substantial budget, and the ability to act decisively when a suitable opportunity arises.

Securing Essential Utilities: Power and Water Considerations

A solar module factory is a sophisticated industrial facility that depends on reliable and cost-effective utilities. In Australia, securing stable access to power and water presents unique challenges that must be addressed during the site selection phase.

The Challenge of Power Stability and Cost

Ironically, a factory producing solar panels requires a substantial and stable supply of electricity to operate its machinery. The Australian National Electricity Market (NEM) is known for its wholesale price volatility. Data from the NEM shows that prices can swing dramatically within a single day, from negative values during periods of high renewable generation to over AUD 300 per megawatt-hour (MWh) during peak demand.

This price fluctuation creates significant uncertainty for energy-intensive businesses, making it difficult to forecast and control operational expenses. Any site evaluation must investigate the local grid connection capacity, network charges, and the potential to mitigate price risk through long-term power purchase agreements or on-site generation and storage.

Water Access: Beyond Turning on the Tap

Water is another critical utility, primarily used for processes like cleaning the glass for solar modules. While urban areas generally offer reliable water access, regional sites may face more complex regulations. Facilities located within the Murray-Darling Basin, for example, must navigate a complex system of water rights, which can be both expensive and restrictive.

Prospective investors will need to verify a potential site’s water supply capacity, connection costs, and any local or state-level restrictions on industrial water usage. Overlooking this detail can lead to unexpected production limits or significant ongoing costs.

Logistics and Supply Chain: Connecting Your Factory to Markets

An efficient logistics network is the circulatory system of a manufacturing plant. For a solar module factory in Australia, this means managing two primary flows: the inbound shipment of raw materials and the outbound distribution of finished products. As many components in the Understanding the Solar Module Bill of Materials (BOM) are imported, proximity to a major seaport is a significant advantage.

Key ports for containerized freight include Melbourne, Sydney, Brisbane, and Fremantle (Perth). A factory located far from these ports will incur substantial domestic transport costs. For example, road freight for a single pallet from Melbourne to Sydney can exceed AUD 1,500. When scaled to the volume of raw materials required for continuous production, these ‘last-mile’ costs can significantly impact profitability.

A thorough site analysis must include a detailed assessment of its proximity to seaports, major highways, and rail networks to ensure an efficient and cost-effective supply chain.

Access to a Skilled Workforce

While automation is central to modern solar manufacturing, a skilled workforce remains essential for operating and maintaining the Key Machinery for a Solar Panel Production Line. Reports from organizations like Engineers Australia consistently highlight skills shortages in technical and engineering roles across the country.

This creates a trade-off for investors:

Metropolitan Areas: Offer a larger and more diverse talent pool but come with higher labor costs and greater competition for skilled workers.

Regional Areas: May offer lower labor costs and potential government incentives but have a smaller pool of experienced technicians and engineers.

The site selection process should include consultation with local employment agencies and educational institutions to gauge the availability of the required skills in the region.

Frequently Asked Questions (FAQ)

Q: How much land is needed for a small-scale solar module factory?

A: A typical semi-automated factory with an annual capacity of 20–50 MW requires a site of approximately 10,000 to 15,000 square meters. This allows for the production hall, warehouse for raw materials and finished goods, office space, and external vehicle access. The specific Factory Building Requirements for Solar Module Manufacturing will dictate the final dimensions.

Q: Can a solar factory be powered entirely by its own solar panels?

A: While a factory can generate a significant portion of its electricity from a rooftop or ground-mounted solar array, achieving 100% self-sufficiency is challenging. Manufacturing often operates 24/7, requiring a constant power source. A grid connection remains essential for stability and to supply power at night or during periods of low solar irradiation. An on-site solar system is best viewed as a tool to reduce grid reliance and hedge against electricity price volatility.

Q: Are there government incentives for choosing a specific region in Australia?

A: Yes, federal, state, and local governments often offer incentives to encourage investment and job creation, particularly in regional areas or designated economic zones. These can include tax concessions, grants for infrastructure development, or streamlined planning approvals. Engaging with state development agencies is the best way to explore available support for a proposed project.

Q: What is more important: cheap land or good logistics?

A: Experience from numerous J.v.G. Technology turnkey projects indicates that while low land cost is attractive initially, superior logistics almost always provides better long-term value. The recurring daily costs of transportation for both raw materials and finished goods can quickly erode the one-time savings from cheaper land. A location with efficient access to ports and domestic markets provides a more sustainable competitive advantage.

Conclusion and Next Steps

Selecting a site for a solar module factory in Australia is a complex decision that extends far beyond buying a parcel of land. It requires a detailed analysis of the interplay between real estate availability, utility costs, logistical efficiency, and workforce access. By carefully evaluating these factors, investors can lay a robust foundation for a successful and profitable manufacturing enterprise.

To deepen your understanding of the market dynamics and strategic considerations for entering this sector, explore the comprehensive Solar Manufacturing Opportunities in Australia: A PVknowhow.com Report.