Disclaimer: This case study represents a composite example derived from real-world

consulting work by J.v.G. Technology GmbH in solar module production and factory optimization. All data points are realistic but simplified for clarity and educational purposes.

For any international entrepreneur, a market with strong government support, a stable economy, and immense untapped natural resources offers a significant opportunity. Chile, with its ambitious goal of generating 70% of its energy from renewables by 2030, presents exactly this scenario.

While large-scale solar farms often capture headlines, a strategic and highly profitable entry point lies in a sector many overlook: distributed generation. Local solar panel manufacturing is poised to meet this growing demand.

This article provides a business plan framework for establishing a small-scale, 50 MW solar module factory in Chile. It’s designed for business professionals who see the potential in this market but need a structured path for entry. The plan focuses on serving the country’s growing residential and commercial rooftop market, a segment where local production offers a distinct competitive advantage.

The Strategic Advantage: Why Chile’s Distributed Generation Market?

Chile’s commitment to renewable energy is more than just a policy statement; it’s backed by tangible incentives and a favorable investment climate. The country’s ‘net-billing’ law allows homeowners and businesses to sell surplus electricity back to the grid, creating a powerful financial incentive to install rooftop solar systems. This policy has ignited demand in the distributed generation (DG) sector, which includes all projects under 300 kW.

Key Market Drivers:

-

High Solar Irradiation: Chile’s Atacama Desert has some of the highest solar irradiation levels in the world, but even its more populated central regions offer excellent conditions for solar energy production. This makes solar a viable investment for a wide range of consumers.

-

Economic Stability: As one of Latin America’s most stable and prosperous nations, Chile provides a secure environment for long-term capital investment.

-

Growing Energy Demand: As a developing economy, Chile requires more power. Solar DG offers a reliable solution, especially in regions where grid infrastructure may be strained.

-

Import Dependency: Currently, most solar modules installed in Chile are imported. A local manufacturing facility can offer significant advantages, including shorter lead times, products customized for local conditions, faster customer support, and the powerful ‘Made in Chile’ brand appeal.

By focusing on the DG market, a 50 MW factory can avoid direct competition with the global Tier 1 manufacturers who dominate the utility-scale sector. Instead, it can position itself as a premium, local provider for installers serving residential and commercial clients.

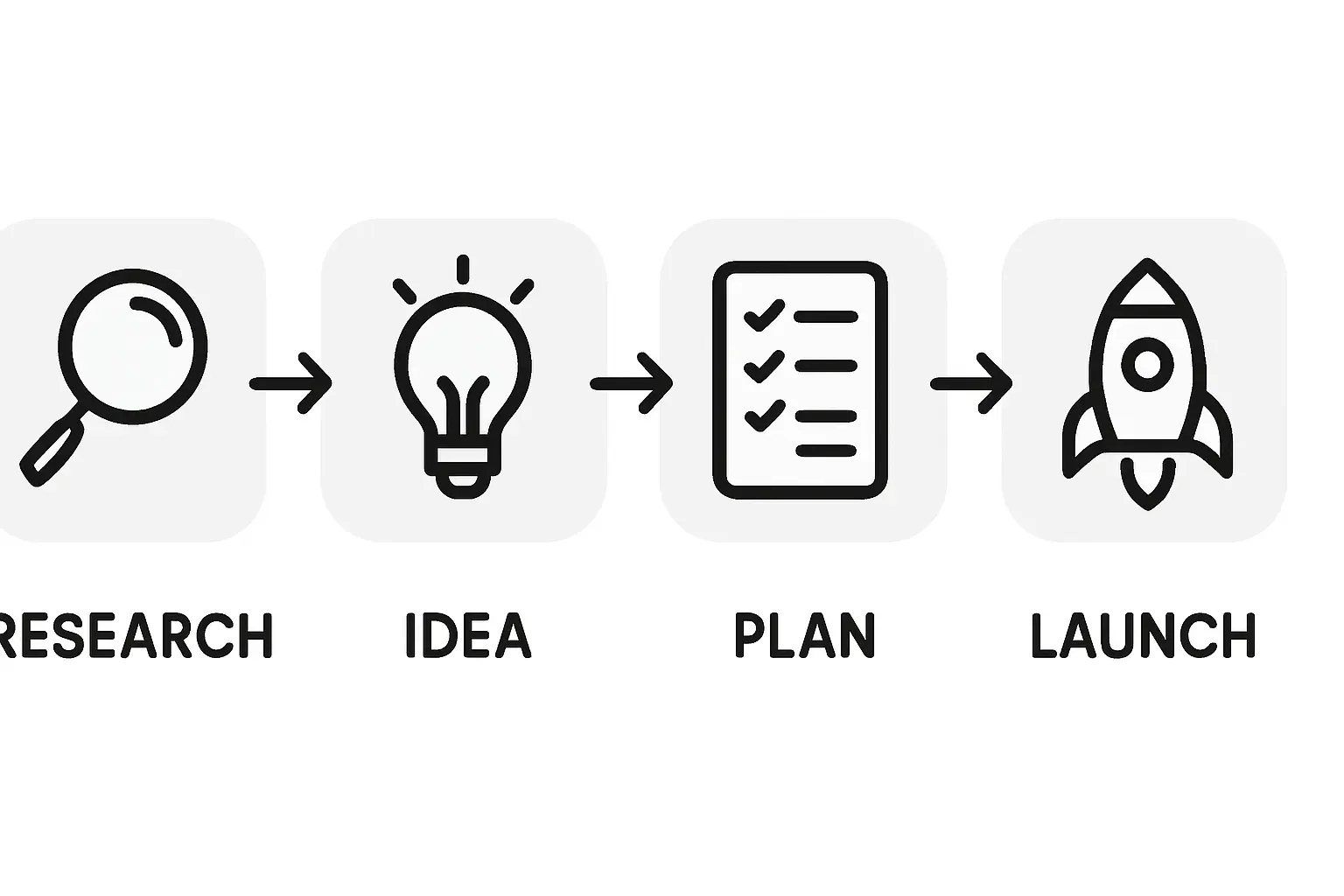

The Phased Implementation Model: From Concept to Operation

Establishing a manufacturing facility in a new country requires a disciplined, step-by-step approach. A rushed process can lead to costly errors in equipment selection, site planning, or regulatory compliance. Experience from EU PV factory turnkey supplier projects shows that a phased implementation is critical for success. The entire process, from the final decision to the first certified module, can typically be completed within 12 months.

Phase 1: Feasibility and Business Planning (Months 1–3)

This foundational phase covers a detailed market analysis, site selection, and the development of a comprehensive financial model. Key activities include securing financing, defining the corporate structure, and creating a robust business plan to guide the entire project.

Phase 2: Equipment Sourcing and Facility Preparation (Months 4–7)

Once the plan is approved, the focus shifts to procuring the core production assets. This step involves selecting and ordering the right solar manufacturing machines to match the desired technology and output. In parallel, the chosen factory building must be prepared with the necessary utilities, flooring, and climate control.

Phase 3: Installation and Commissioning (Months 8–10)

This phase is the technical heart of the project. Engineers install and commission the full production line, from the stringer to the final laminator and tester. A turnkey solar panel factory approach ensures all equipment works together seamlessly under the management of experienced technicians.

Phase 4: Staff Training, Ramp-Up, and Certification (Months 11–12)

With the machinery in place, local staff are trained in operational and quality control protocols. The factory begins pilot production, gradually increasing output to test and refine its processes. During this time, sample modules are sent to accredited laboratories for the solar module certification process, a crucial step for market access and bankability.

Understanding the Financial Projections for a 50 MW Line

For any business professional, the numbers have to be sound. A 50 MW solar factory is a significant but manageable industrial investment. The following figures provide an illustrative overview based on current market data.

Capital Expenditure (CapEx)

The total one-time investment to set up the factory includes:

-

Production Machinery: The largest component, covering all stages of module assembly.

-

Building and Infrastructure: Costs for acquiring or leasing a suitable facility (approx. 3,000–4,000 sq. meters) and making necessary modifications.

-

Initial Raw Material Stock: A two- to three-month supply of glass, cells, EVA, backsheets, and frames.

-

Logistics, Installation and Training: Costs associated with shipping, expert supervision, and knowledge transfer.

Operational Expenditure (OpEx)

The recurring monthly costs to run the factory include:

-

Raw Materials (Bill of Materials – BOM): This accounts for over 80% of a finished module’s cost.

-

Labor: A 50 MW line typically requires 25–35 employees, including operators, engineers, and administrative personnel.

-

Utilities: Primarily electricity to run the machinery.

-

Maintenance and Consumables: Spare parts and other operational necessities.

With efficient operations and a strong sales strategy focused on the higher-margin DG market, a well-run 50 MW factory in Chile can achieve profitability within its second year and a full return on investment in approximately five to seven years.

Navigating Potential Challenges

While the opportunity is clear, any new industrial venture involves challenges. Proactive planning is essential for mitigating these risks.

-

Supply Chain Management: Securing a reliable and cost-effective supply of raw materials, particularly solar cells and glass, is paramount. Establishing relationships with multiple suppliers is a key risk-mitigation strategy.

-

Skilled Labor: Although much of the production process is automated, a core team of trained technicians and quality control managers is essential. A robust training program, often included in turnkey packages, is critical.

-

Regulatory Navigation: Understanding local import duties, tax incentives, and environmental regulations is vital. Working with local partners can streamline this process significantly.

These challenges are not insurmountable but are standard hurdles that can be managed effectively with experienced guidance. To help new entrants, the pvknowhow.com platform provides educational resources, including a structured e-course, to help you navigate these complexities with confidence.

Frequently Asked Questions

Why start with 50 MW instead of a larger factory?

A 50 MW facility provides the ideal balance of manageable investment and meaningful market impact. It allows an entrepreneur to establish a brand and capture a significant share of the regional DG market without engaging in a high-stakes capital war with large international conglomerates. It also offers the flexibility to scale up operations as market share grows.

What kind of building is required for a solar factory?

A standard industrial hall of approximately 3,000–4,000 square meters is usually sufficient. Key requirements include a minimum ceiling height of six meters, a solid industrial floor, and reliable access to three-phase electricity and water.

Do I need to be a solar engineer to start this business?

No. The entrepreneur’s role is to provide the vision, capital, and business leadership. The technical aspects of setting up and running the factory can be handled through a turnkey solution provider and by hiring a qualified local operations manager. At pvknowhow.com, our message is simple: ‘You don’t need to be an expert – we’ll guide you.’

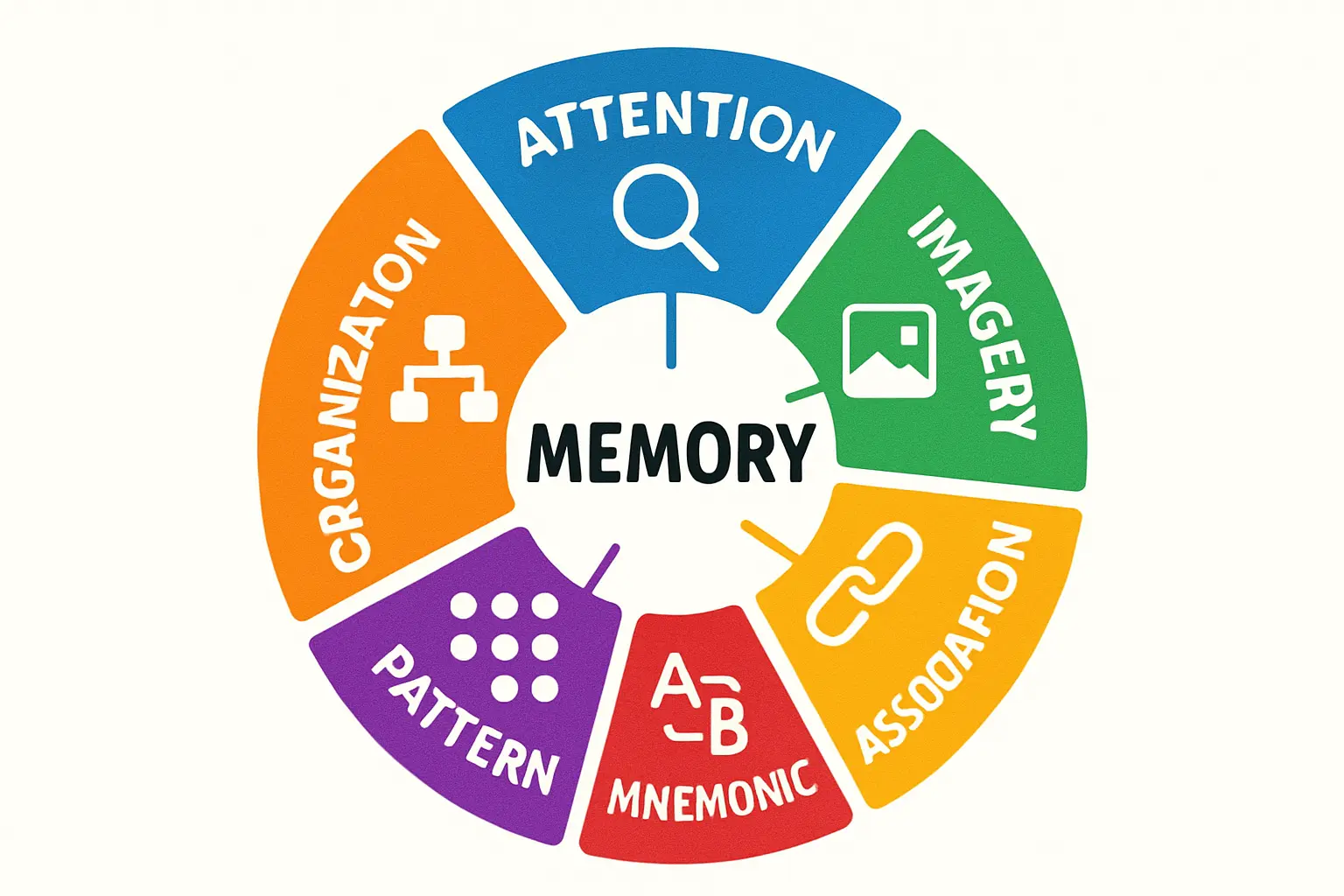

How is product quality ensured?

Quality is ensured through a multi-layered approach that includes sourcing certified raw materials, using reliable and automated machinery, implementing strict quality checks at each production step (e.g., EL testing, sun simulation), and finally, obtaining international certifications like IEC 61215.

Download: 50 MW Chile Factory Business Plan (PDF)

Author: This case study was prepared by the

turnkey solar module production specialists at J.V.G. Technology GmbH

It is based on real data and consulting experience from J.v.G. projects

worldwide, including installations ranging from 20 MW to 500 MW capacity.