An investor sees immense potential in Australia’s solar market, driven by government initiatives like the ‘Solar Sunshot’ program and a strong public appetite for renewable energy. He assumes that with enough capital and the right technology, establishing a solar module factory is a straightforward venture. Several months into planning, however, the project stalls—caught in a complex web of state environmental permits, federal product certifications, and local council zoning laws he was entirely unprepared for.

This scenario is common for entrepreneurs entering a new, highly regulated market. The Australian regulatory landscape for manufacturing is comprehensive and multi-layered. Understanding this roadmap isn’t merely a bureaucratic step; it is a critical component of due diligence that determines a project’s feasibility, timeline, and ultimate profitability.

This guide provides a clear overview of the key permits, standards, and compliance obligations for establishing and operating a solar module production facility in Australia.

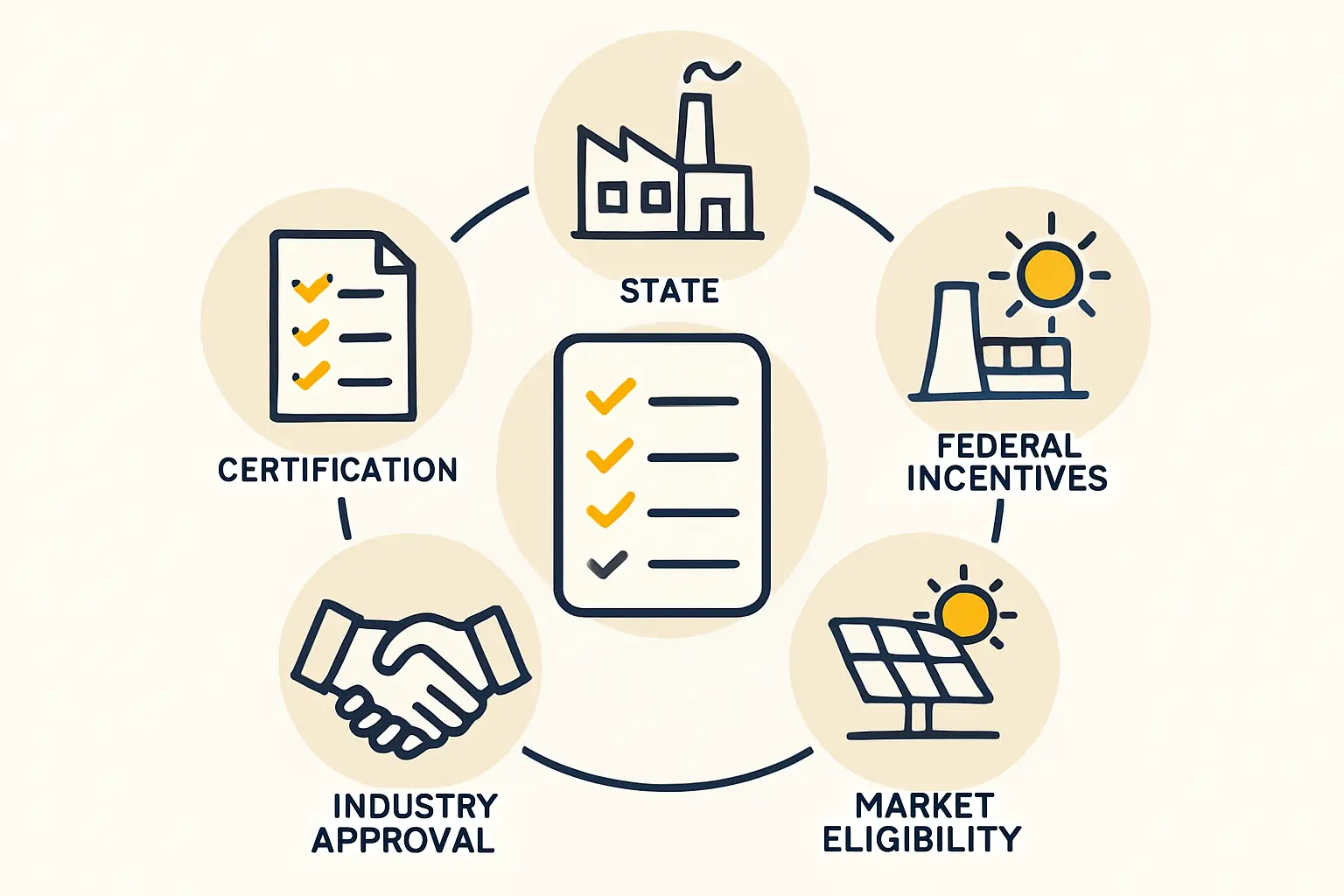

Understanding Australia’s Dual-Layer Regulatory System

Successfully navigating the Australian regulatory environment starts with understanding its fundamental structure: a division of power between the federal government and individual state or territory governments. A solar manufacturing project must satisfy requirements at both levels.

Federal Jurisdiction: The national government oversees matters that affect the country as a whole. For a solar manufacturer, this includes:

- Product Standards and Safety: Setting national safety and performance benchmarks for modules.

- Consumer Law: Governing warranties and product quality guarantees.

- National Renewable Energy Schemes: Administering programs like the Renewable Energy Target (RET).

- Import/Export Controls: Managing the flow of materials and finished goods across the border.

State/Territory Jurisdiction: Day-to-day operational and establishment regulations fall to the states and territories, which approve and monitor the physical factory. Key areas include:

- Planning and Zoning: Approving the location and construction of the facility.

- Environmental Protection: Licensing and monitoring waste, emissions, and pollution.

- Work Health and Safety (WHS): Ensuring a safe working environment for all employees.

These two layers are not sequential but parallel. A project requires a coordinated strategy to address both federal product requirements and state-level operational approvals right from the beginning.

Key federal bodies like the Clean Energy Regulator (CER) and the Clean Energy Council (CEC) set the rules for market participation, while state-based Environmental Protection Authorities (EPAs) and planning departments grant the license to operate. A detailed exploration of the Solar Manufacturing Opportunities in Australia: A PVknowhow.com Report further outlines how these bodies influence market dynamics.

Securing Your Foundation: State-Level Approvals

Before a single module can be produced, the factory itself must be approved. This process, governed at the state or territory level, is one of the most significant project milestones.

Development Approval (DA)

The Development Approval is the primary planning permit needed to construct and operate an industrial facility. Submitted to a local council or state planning authority, this comprehensive application assesses the project’s local impact, covering:

- Zoning Compliance: Ensuring the proposed land is designated for industrial use.

- Building Codes: Adherence to national construction standards.

- Environmental Impact: Management of noise, traffic, and visual amenity.

- Waste Management: Plans for handling both general and industrial waste.

The DA process can be lengthy and varies significantly between states like New South Wales and Victoria. Early engagement with local authorities is essential to understand their specific requirements.

Environmental Protection Licensing

Every Australian state has an Environmental Protection Authority (EPA) responsible for preventing pollution. As an industrial operation, a solar module factory requires an EPA license to operate. The application focuses on how the facility will manage its environmental footprint, including:

- Air Emissions: Control of dust (e.g., silicon dust) and fumes from chemical processes.

- Water Management: Treatment of wastewater and prevention of runoff into local waterways.

- Waste Disposal: A clear, compliant plan for disposing of manufacturing by-products like broken glass, off-cut silicon, and used chemicals.

Failure to meet EPA standards can result in significant fines and operational shutdowns, making this a critical area of compliance.

Work Health and Safety (WHS)

Australia maintains very high standards for workplace safety. State-based WHS (also known as OH&S) laws require manufacturers to establish and maintain a safe working environment. This involves comprehensive risk assessments for all processes, from handling heavy glass sheets with key solar panel manufacturing machines to storing production chemicals. A documented safety management system and thorough employee training are not optional—they are legal requirements.

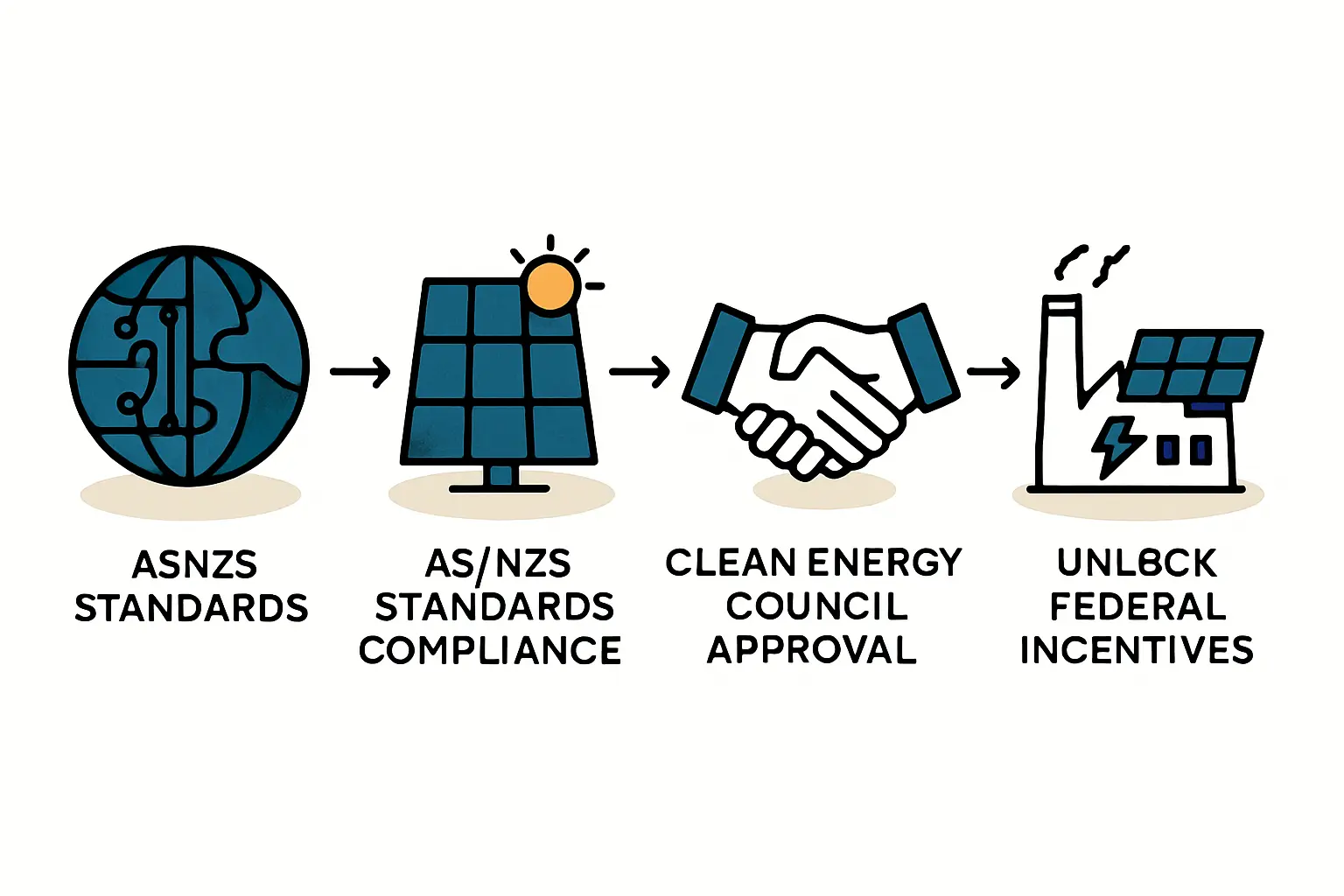

The Gateway to the Market: Federal Product Certification

Obtaining state-level approval allows you to build and run a factory. Federal product certifications, however, determine whether you can sell your modules in the Australian market.

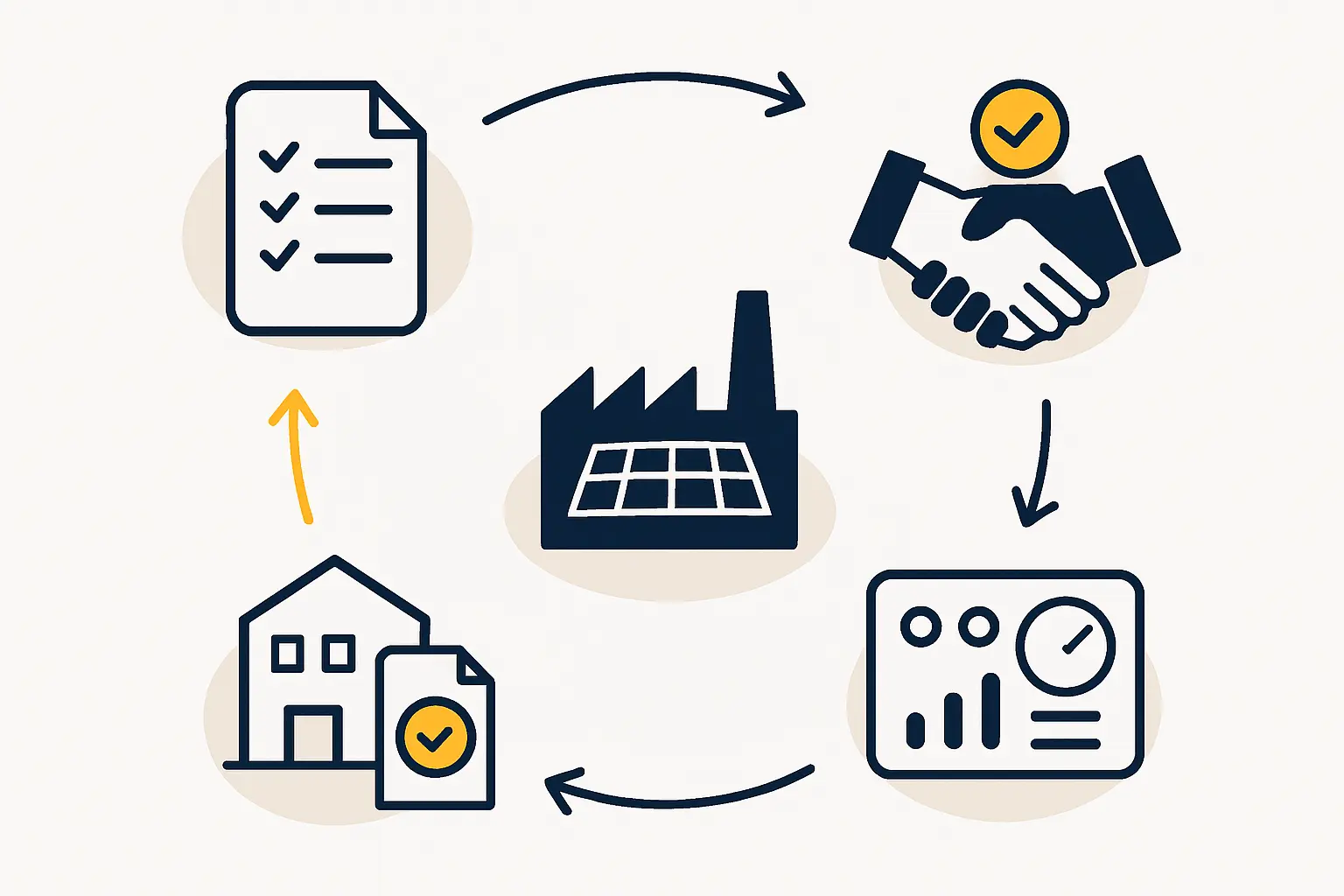

The Clean Energy Council (CEC) Listing: A Commercial Necessity

While not a direct government body, the Clean Energy Council maintains a list of approved modules and inverters. For a solar module to be eligible for Small-scale Technology Certificates (STCs)—a key financial incentive under the government’s Renewable Energy Target—it must be on the CEC list.

As a result, CEC listing has become a de-facto market access requirement, as wholesalers, installers, and customers almost exclusively demand CEC-approved modules. For a new manufacturer, navigating the CEC approval process is a major undertaking.

The process involves two main stages:

-

IEC Certification: The module must first be certified to international standards by an accredited laboratory. The core standards are IEC 61215 (performance) and IEC 61730 (safety).

-

CEC Application and Audit: After obtaining IEC certification, the manufacturer applies to the CEC, submitting test data and undergoing a factory audit to verify that production processes meet the required quality standards.

Investors often underestimate the time and expense this involves. It’s a critical path item that must be factored into the business plan from day one.

Standards Australia and the Australian Consumer Law (ACL)

Beyond the CEC, modules must comply with relevant Australian Standards (AS/NZS). All products sold in Australia are also subject to the Australian Consumer Law (ACL). This federal law holds manufacturers accountable for product safety, performance claims, and warranties. All marketing materials and specification sheets must be accurate, and the company must have a clear process for handling warranty claims.

Navigating Future Opportunities: The ‘Solar Sunshot’ Program

The Australian government’s ‘Solar Sunshot’ program aims to stimulate domestic solar manufacturing. While full details are still emerging, the initiative is expected to introduce a new layer of regulatory and commercial considerations. These may include:

- Financial Incentives: Grants or subsidies for locally produced modules.

- Local Content Requirements: Preferential treatment in government tenders for projects using Australian-made components.

- Streamlined Approvals: Potential for fast-tracking permits for qualifying projects.

Entrepreneurs planning to enter the market should monitor these developments closely. Participating in such programs will likely bring its own compliance and reporting obligations but also offer significant commercial advantages. Understanding the full picture of how to start a solar module factory in this evolving landscape is more important than ever.

Frequently Asked Questions (FAQ)

How long does the entire regulatory approval process typically take?

From initial planning to final certification, a new entrant should budget for 12 to 24 months. This timeline can be affected by site complexity, the efficiency of state planning bodies, and the rigorous demands of the CEC product listing process.

Is international IEC certification sufficient to sell solar modules in Australia?

No. While IEC 61215 and IEC 61730 certifications are a mandatory prerequisite, they are not sufficient on their own. For commercial viability, Clean Energy Council (CEC) listing is essential to access the mainstream market and government incentive schemes.

What are the most common regulatory mistakes new manufacturers make?

The most frequent errors are underestimating the time and cost associated with state-level environmental approvals and the federal CEC listing process. Another common oversight is failing to integrate strict Australian Work Health and Safety (WHS) requirements into the factory design and operational plans from the outset.

Are the investment requirements higher in Australia due to these regulations?

These regulations add compliance costs and extend project timelines, which must be factored into the initial investment requirements for setting up a solar module production line. Costs for consulting, testing, certification, and implementing compliant waste management and safety systems are significant and should not be overlooked in the business plan.

A Roadmap for Success

Australia offers a substantial opportunity for solar module manufacturing, but it is not a market to enter lightly. The regulatory path is intricate, spanning federal and state jurisdictions with demanding requirements for both operational permits and product certifications.

Success depends on a structured, informed approach. By understanding the distinct roles of state planning authorities, EPAs, and the federal CEC, an investor can develop a realistic project timeline and budget. The key is to treat regulatory compliance not as a final hurdle but as a core pillar of the business strategy from day one. With expert guidance, such as that from a turnkey solar manufacturing line partner familiar with these processes, this complex roadmap becomes a clear and navigable path to establishing a successful Australian manufacturing operation.