Disclaimer: This case study represents a composite example derived from real-world

consulting work by J.v.G. Technology GmbH in solar module production and factory optimization. All data points are realistic but simplified for clarity and educational purposes.

The global energy transition presents nations with a choice: to be consumers of new technologies or to become architects of their own energy future. For the Kingdom of Bahrain, a unique opportunity has emerged to establish itself as a central pillar of the GCC’s renewable energy supply chain. This is not merely an industrial project but a strategic national initiative with implications for economic diversification, energy security, and regional leadership.

This analysis lays out a comprehensive investment blueprint for establishing a 1-2 GW automated solar module gigafactory in Bahrain. It covers the project’s strategic alignment with national ambitions and its financial and technical framework, presenting a clear path to capturing the vast export market created by giga-projects in neighboring Saudi Arabia and across the GCC.

The Confluence of Vision and Opportunity in the GCC

The Gulf Cooperation Council (GCC) is undergoing one of the most ambitious economic transformations in modern history. At the heart of this shift are national strategies like Saudi Arabia’s Vision 2030, which call for a massive expansion of renewable energy capacity. Projects such as NEOM, the Red Sea Project, and ROSHN are not just building cities; they are creating predictable, long-term demand for hundreds of gigawatts of solar power.

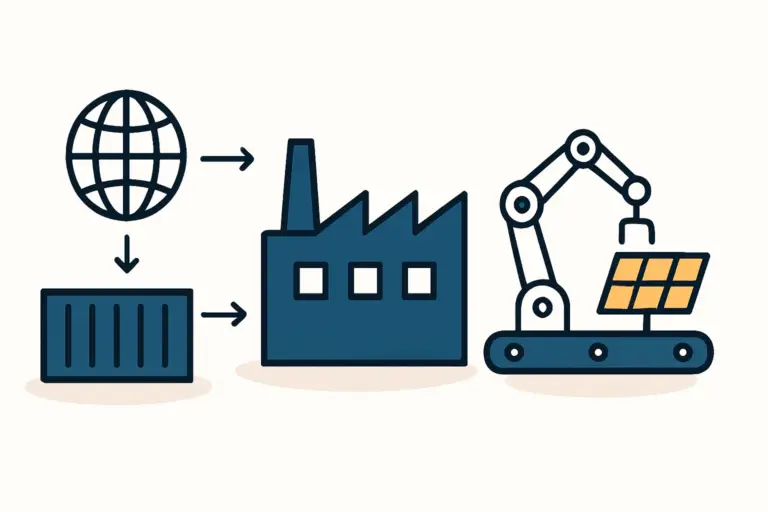

This explosive growth creates a substantial market for high-quality solar modules. A manufacturing facility within the GCC is strategically positioned to serve this demand, satisfying local content requirements and de-risking supply chains for these critical national projects. The question is not whether the demand exists, but who is best positioned to meet it.

Bahrain as the Strategic Manufacturing Hub

While several locations could be considered, the Kingdom of Bahrain offers a compelling combination of logistical, economic, and industrial advantages that make it an ideal hub for a solar module gigafactory.

Unmatched Logistical Access to Key Markets

Bahrain’s geographic location, enhanced by world-class infrastructure, offers direct and efficient access to the largest market in the region. The King Fahd Causeway provides a direct land bridge to Saudi Arabia, enabling seamless, cost-effective transport of finished solar modules to project sites.

Meanwhile, the Khalifa bin Salman Port provides global access for sourcing raw materials and exporting to the wider region. This logistical efficiency is a critical competitive advantage, reducing both costs and delivery times.

Alignment with Bahrain’s Economic Vision 2030

Establishing a high-tech manufacturing facility aligns perfectly with the principles of Bahrain’s Economic Vision 2030. The project directly contributes to key national goals:

- Economic Diversification: It creates a new, non-oil-based industrial sector, generating sustainable revenue streams.

- Sustainability: It places Bahrain at the forefront of the clean energy transition, producing the very technology required to meet regional climate goals.

- High-Skill Job Creation: An automated factory requires skilled technicians, engineers, and management professionals, fostering the development of a future-ready workforce.

A Favorable Investment and Industrial Ecosystem

Bahrain is renowned for its business-friendly environment, offering 100% foreign ownership in manufacturing and a zero-percent corporate tax rate. This stable and predictable regulatory framework is essential for a long-term investment of this scale.

A unique local advantage is Bahrain’s world-class aluminum industry, led by Aluminium Bahrain (Alba). This synergy creates a powerful opportunity to source high-quality aluminum frames for solar modules locally. Such a move would strengthen the domestic supply chain, reduce import dependency, and enhance the ‘Made in Bahrain’ value proposition.

Financial and Technical Framework for a 1-2 GW Gigafactory

A project of this magnitude requires a robust plan grounded in proven technology and realistic financial modeling. The approach focuses on leveraging automation and specialized technology to ensure quality, efficiency, and long-term viability.

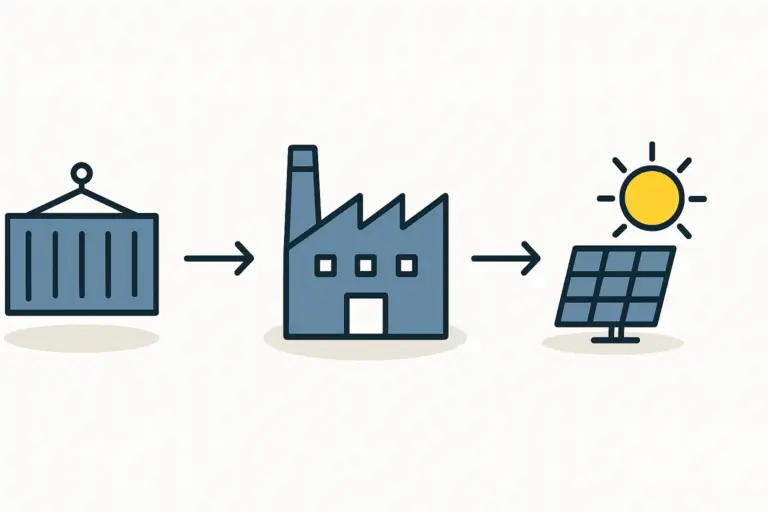

Defining the Gigawatt Scale: Investment and Output

A 1-gigawatt (GW) factory produces approximately 2 million solar panels per year, enough to power over 200,000 homes. Scaling to 2 GW doubles this output, establishing the facility as a major regional supplier.

The initial investment for a 1 GW facility of this sophistication typically ranges from $70 million to $120 million USD. This includes the building, infrastructure, and a fully automated turnkey solar manufacturing line. The project can adopt a phased approach, starting with 1 GW and scaling to 2 GW as market demand is secured. The return on investment is measured not only in financial terms but also in the strategic value of energy independence and industrial leadership.

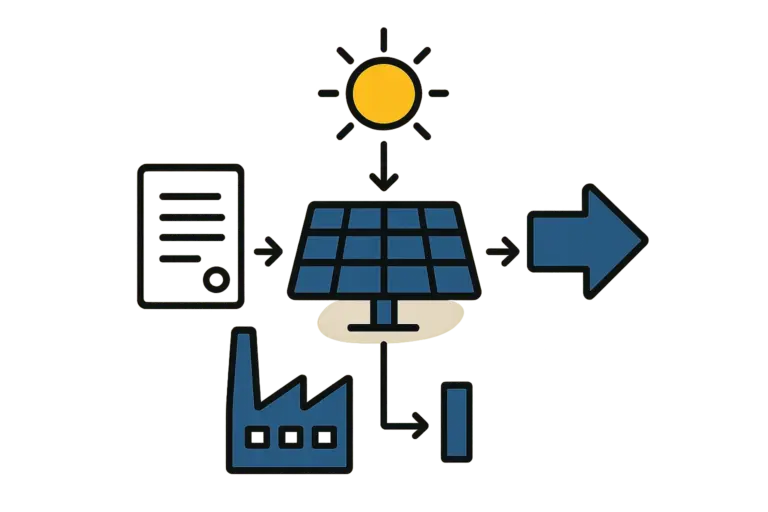

The Technology Imperative: Localizing PV Production Standards and Equipment

Standard solar manufacturing equipment is not designed for the unique environmental challenges of the GCC region—high ambient temperatures, humidity, and airborne dust and sand. These factors can compromise production efficiency and the long-term reliability of finished modules.

Based on decades of experience, A professional European turnkey supplier has developed the innovative methodology for optimizing material flow and minimizing operational risk. This specialized suite of solar manufacturing equipment is engineered specifically for desert climates. Key features include:

- Enhanced Climate Control: Specialized cooling and dehumidification systems maintain optimal production conditions, ensuring consistent quality regardless of external weather.

- Advanced Sealing and Filtration: The machinery is protected against fine sand and dust intrusion, minimizing downtime and maintenance costs.

- High-Grade Automation: A fully automated line reduces manual handling, increases throughput, and ensures every module meets the highest international quality standards (e.g., TÜV, IEC).

This technological specialization is not a luxury but a necessity for ensuring the bankability and long-term performance of modules produced in the region.

Phased Implementation and Operational Timeline

A well-structured project plan can take a gigafactory from a final investment decision to its first module production in approximately 18 to 24 months.

The process, guided by an experienced turnkey partner like premier EU provider, covers every stage from factory layout planning and equipment installation to final commissioning and staff training. This structured approach mitigates risk and ensures a smooth ramp-up to full production capacity.

Frequently Asked Questions (FAQ) for Sovereign Planners

What is the primary market for a Bahrain-based gigafactory?

The primary target is Saudi Arabia’s giga-projects (NEOM, Red Sea Global, etc.), which require a massive and reliable supply of high-quality modules. A Bahraini facility can qualify as a local GCC supplier. Secondary markets include large-scale solar projects in the UAE, Kuwait, and Oman.

How many jobs can a facility of this scale create?

A 1-2 GW automated gigafactory directly employs between 200 and 350 highly skilled personnel, including engineers, technicians, quality control specialists, and administrative staff. It also creates significant indirect employment in logistics, material supply, and maintenance services.

How are supply chain risks for raw materials managed?

A diversified sourcing strategy is critical. While key materials like polysilicon and solar cells are primarily sourced from established global markets, a Bahraini location with a major seaport allows for flexible procurement from multiple international suppliers. The local availability of aluminum for frames is a significant de-risking factor.

Why is a specialized GCC?

Producing high-performance, 25+ year-warranted solar modules requires precise environmental control. Standard equipment operating in the GCC’s heat and humidity would suffer from lower yields and higher defect rates. To mitigate this critical risk, the specialized GCC is an insurance policy for quality and long-term profitability.

Conclusion: From Blueprint to National Asset

The establishment of a solar gigafactory in Bahrain is more than an industrial investment; it is a declaration of strategic intent. It positions the Kingdom as a critical enabler of the GCC’s energy transition, turning regional demand into a catalyst for its own economic development.

By leveraging its unique logistical advantages and aligning with its national vision, Bahrain can deploy state-of-the-art, climate-specific manufacturing technology to build a resilient, profitable, and strategically vital national asset. This blueprint provides the framework for that vision, charting a clear path toward transforming sand and sun into sustainable economic strength and regional leadership.

Download the Bahrain Solar Module Manufacturing Case Study (PDF)

Author: This case study was prepared by the

turnkey solar module production specialists at J.V.G. Technology GmbH

It is based on real data and consulting experience from J.v.G. projects

worldwide, including installations ranging from 20 MW to 500 MW capacity.