Disclaimer: This case study represents a composite example derived from real-world

consulting work by J.v.G. Technology GmbH in solar module production and factory optimization. All data points are realistic but simplified for clarity and educational purposes.

For established Engineering, Procurement, and Construction (EPC) firms in Bahrain, the rhythm of a major solar project—planning, procurement, and installation—is familiar. Yet, a critical component of this process often lies outside their direct control: the supply of solar modules. Delays at a distant port, unforeseen price hikes, or inconsistent quality can disrupt even the most carefully planned project, squeezing both margins and timelines.

This reliance on imported modules represents not just a strategic vulnerability but also a powerful opportunity. As Bahrain advances towards its National Renewable Energy Action Plan (NREAP) targets, the most forward-thinking EPC and construction leaders are looking beyond project execution. They are considering a strategic move into manufacturing, transforming a supply chain risk into a competitive advantage and a new engine for growth. This guide outlines the business case for vertical integration and provides a practical roadmap for navigating this transition.

The Bahraini Solar Landscape: An Opportunity Defined by a Gap

Bahrain’s commitment to diversifying its energy mix is clear. The NREAP sets a goal of achieving 710 MW of renewable energy capacity by 2035. With current installed capacity at approximately 380 MW—largely from projects like the Al Dur II solar plant—a clear and quantifiable demand gap of over 300 MW remains. This gap represents a predictable, long-term market for solar modules that must be filled in the coming decade.

This government-mandated growth creates a stable foundation for investment. For an EPC firm, the demand for its core services is poised for consistent expansion. The critical question, however, becomes how to secure the most vital component of that service—the solar module—in a way that maximizes profitability and control.

The EPC’s Dilemma: Navigating the Risks of Import Dependency

Currently, the Bahraini market overwhelmingly relies on solar modules imported from international suppliers, primarily in China. While this model has been functional, it exposes local companies to a host of business risks that are becoming increasingly difficult to ignore:

-

Supply Chain Volatility: Global shipping delays, port congestion, and geopolitical factors can interrupt the flow of goods, pushing project timelines back by weeks or even months.

-

Price Fluctuations: Dependence on foreign markets creates exposure to currency fluctuations, changes in international trade policies, and volatile raw material costs, making it difficult to maintain stable project budgets.

-

Quality Control Challenges: Verifying the quality and performance specifications of modules produced thousands of kilometers away is a complex task. A single underperforming batch can compromise the integrity and bankability of an entire solar plant.

These challenges are not merely operational inconveniences; they represent fundamental threats to project profitability and a company’s reputation. Relying on a long and unpredictable supply chain means ceding control over a critical element of your business.

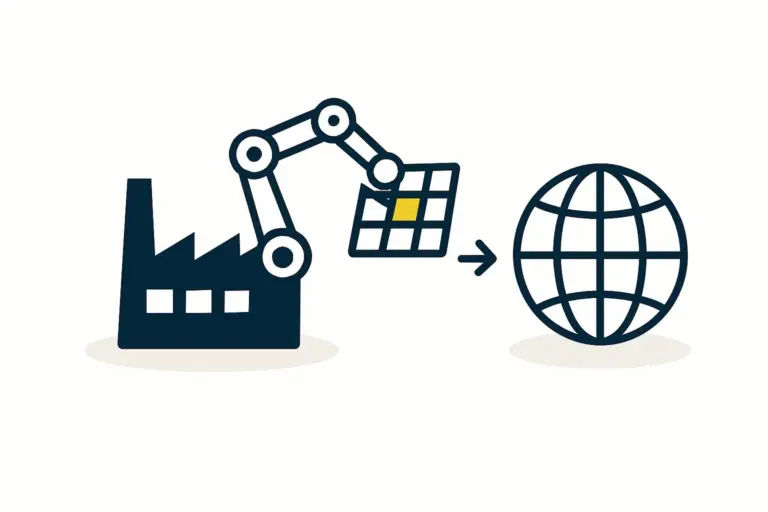

The Strategic Solution: Vertical Integration into Module Manufacturing

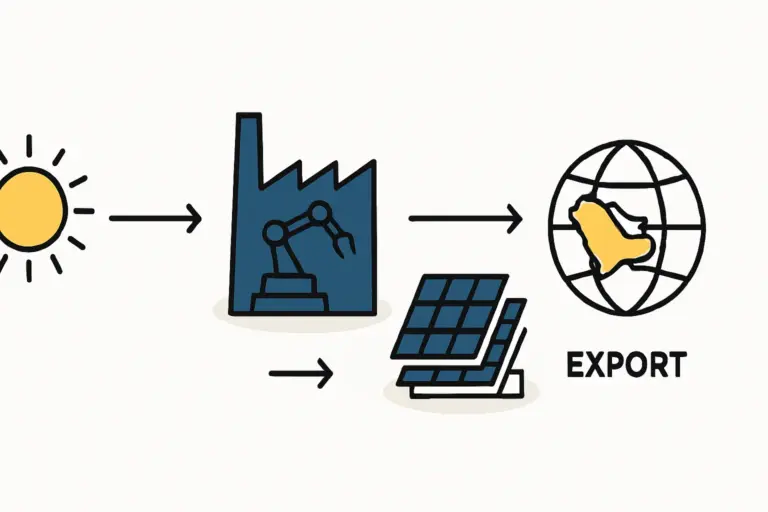

Vertical integration is the strategic response to this challenge. By establishing local solar module manufacturing capabilities, a Bahraini EPC firm can directly address the vulnerabilities of an import-dependent model. The benefits are extensive and align perfectly with national economic goals.

Key Advantages for an EPC Firm:

-

Secure the Supply Chain: Producing modules in-house guarantees a reliable supply for your own large-scale projects, eliminating uncertainty and delays.

-

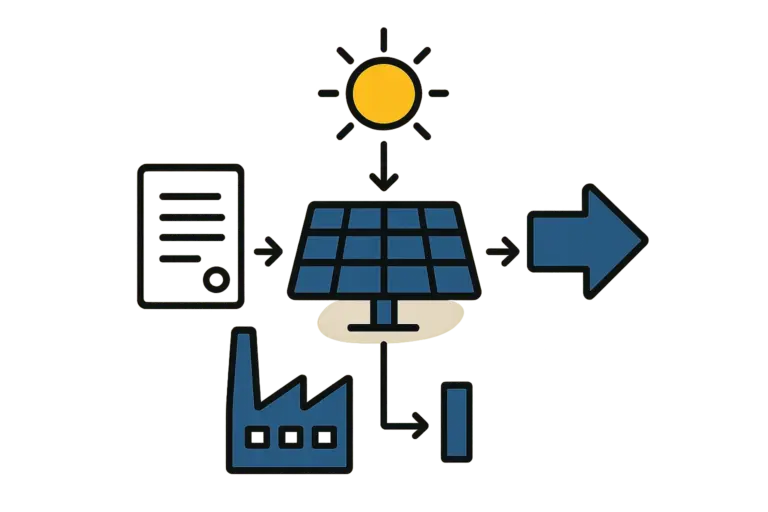

Ensure Quality Assurance: Direct oversight of the entire solar module production process allows for rigorous quality control, ensuring every module meets the precise technical specifications required for the region’s climate.

-

Manage Costs and Margins: Local production insulates your business from global price shocks and shipping costs, leading to more predictable project margins and more competitive bidding.

-

Create New Revenue Streams: Beyond fulfilling internal demand, a local factory can supply modules to other developers in Bahrain and export to the burgeoning solar markets across the GCC.

-

Align with National Vision: This move aligns strongly with the Bahrain Economic Vision 2030, which prioritizes economic diversification, industrialization, and the creation of high-value local employment.

A Blueprint for Entry: The Turnkey Manufacturing Model

The prospect of entering a new, technical field like manufacturing can seem daunting for a company specializing in construction and project management. This is where the turnkey factory model provides a structured, de-risked pathway.

A turnkey solar module manufacturing line is a complete solution in which an experienced engineering partner manages the entire setup process. Based on experience from complex turnkey engineering projects, a 50 MW production facility is an ideal entry point for a market like Bahrain. It is large enough to be commercially viable yet scalable for future growth.

The typical investment required for such a 50 MW setup ranges from USD 4–6 million. This investment covers everything from initial planning and equipment sourcing to on-site installation, commissioning, and staff training.

This model effectively transfers the technical risk to the engineering partner. The EPC firm contributes its business acumen, local market knowledge, and project management oversight, while the partner brings the specialized manufacturing expertise.

Beyond Business: Building National Capacity and Expertise

Establishing a local solar module factory creates value that extends far beyond a single company’s balance sheet. It serves as a catalyst for developing a domestic renewable energy ecosystem.

A 50 MW factory is estimated to create 30 to 50 new, skilled jobs for Bahraini technicians, engineers, and operators. This not only contributes to the local economy but also facilitates crucial technology transfer, building a foundation of advanced manufacturing expertise within the Kingdom.

Furthermore, a ‘Made in Bahrain’ solar module holds significant commercial and patriotic appeal. It positions the manufacturing company as a key player in the nation’s energy transition and opens doors for preferential treatment in government tenders and for export to neighboring countries pursuing similar strategic goals.

Frequently Asked Questions (FAQ)

What is the typical timeline to set up a 50 MW solar factory?

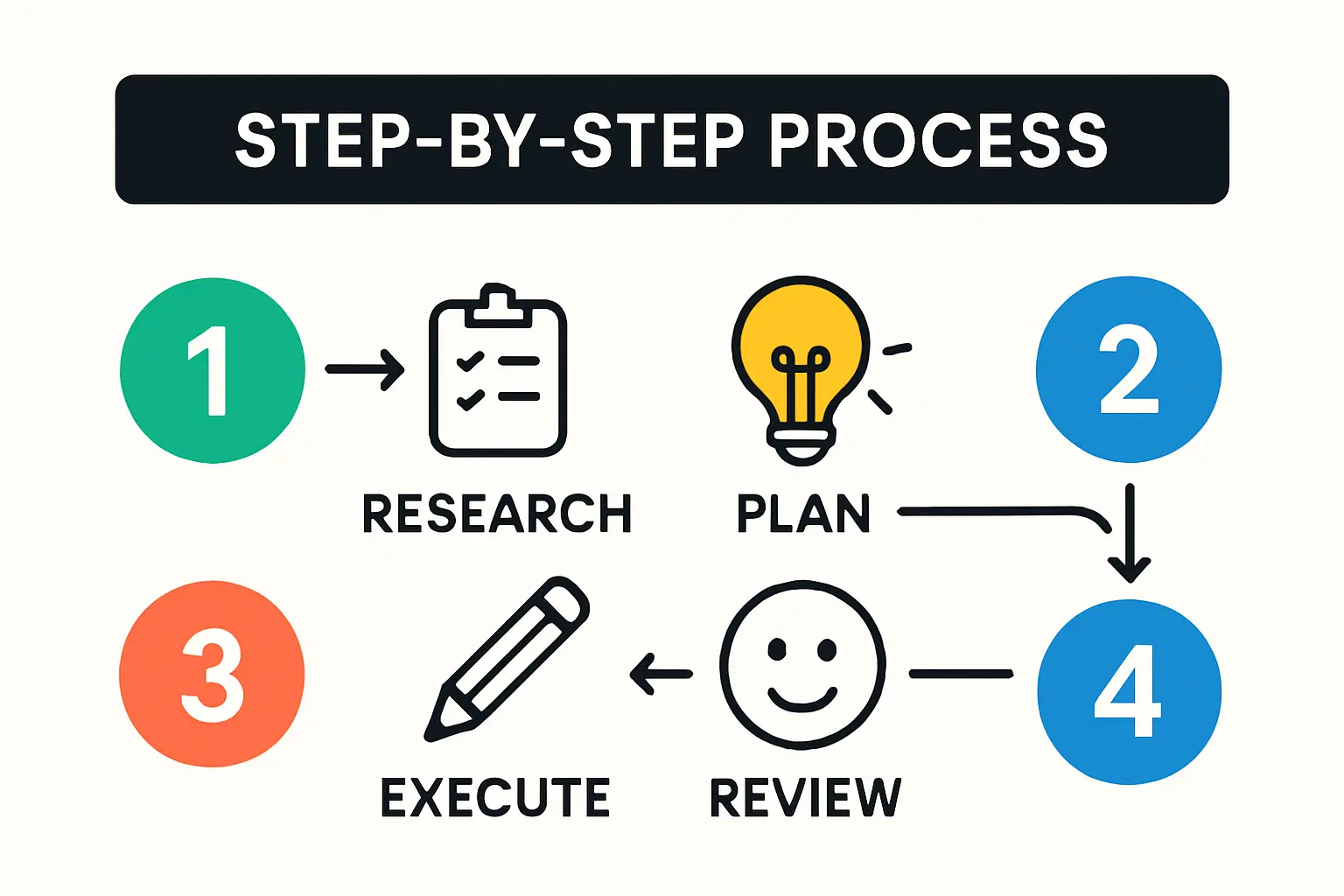

With an experienced turnkey partner, the process from project confirmation to the first module produced typically takes between 9 and 12 months. This includes factory planning, equipment manufacturing, shipping, installation, and commissioning.

Do I need a personal background in solar engineering to run a factory?

No. The primary requirement is strong business and management experience. A turnkey provider like EU PV factory turnkey supplier delivers the complete technical package—the machinery, the processes, and the training for your local staff. Your role is to manage the business, while the technology is managed by the proven system provided.

What are the main operational challenges for a new manufacturer?

The two main initial challenges are establishing a reliable supply chain for raw materials (the Bill of Materials) and navigating the process for international product certifications (like IEC). A capable partner will provide guidance and established contacts to streamline both of these critical steps.

How much physical space is required for a 50 MW line?

A well-designed 50 MW facility requires a building with approximately 3,000 to 5,000 square meters of floor space. This accommodates the production line, warehousing for raw materials and finished goods, and administrative offices. For more detailed information, one can review guides on factory planning and layout.

A Strategic Path Forward

For Bahraini EPC and construction firms, vertical integration into solar module manufacturing is more than an expansion—it is a strategic evolution. This is a calculated move to de-risk operations, control a critical part of the value chain, and capitalize on the nation’s clear commitment to renewable energy.

The transition from project developer to producer is a well-defined process, not an insurmountable technical leap. By partnering with an experienced engineering firm, a company can build a new pillar of its business on a foundation of proven technology and strategic foresight. To fully grasp the operational and financial dimensions of such a venture, exploring a sample business plan or a structured e-course can provide the detailed understanding needed to take the next step.

Access the Bahrain Solar Module Manufacturing case study in your free PDF today

Author: This case study was prepared by the

turnkey solar module production specialists at J.V.G. Technology GmbH

It is based on real data and consulting experience from J.v.G. projects

worldwide, including installations ranging from 20 MW to 500 MW capacity.