Disclaimer: This case study represents a composite example derived from real-world

consulting work by J.v.G. Technology GmbH in solar module production and factory optimization. All data points are realistic but simplified for clarity and educational purposes.

Many entrepreneurs see the immense potential of the solar market across the Americas. Yet, they often face a strategic dilemma: a factory in the United States means high operational costs, while a facility in South America creates logistical hurdles for reaching the lucrative North American market. This dilemma creates a perceived barrier, suggesting a choice must be made between serving the northern or southern continent.

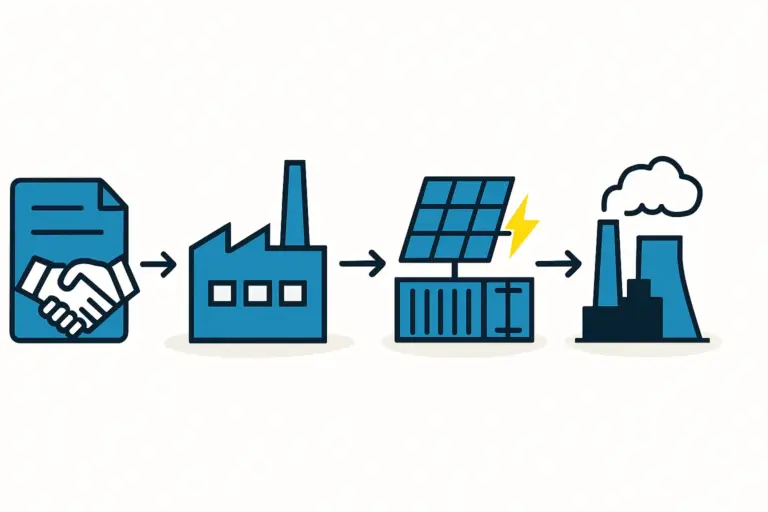

A more strategic perspective, however, reveals a powerful alternative. By establishing a manufacturing hub in Mexico, a business can effectively serve both markets from a single, cost-effective location. This article explores the business case for this approach, detailing the logistical advantages, the critical challenge of dual certification standards, and how a well-planned facility can unlock the entire Pan-American solar market.

For those considering this path, the essential first step is understanding the fundamentals of how to start a solar panel manufacturing business.

The Pan-American Opportunity: A Tale of Two Markets

The demand for solar energy across the Americas is robust, but it’s driven by different factors in each region. A successful Pan-American strategy must recognize and cater to these distinct market dynamics.

North America (Primarily the U.S. and Canada)

The market here is heavily influenced by government policy, such as the Inflation Reduction Act (IRA) in the United States. These incentives are designed to encourage domestic manufacturing and deployment of renewable energy. The demand is for high-efficiency, durable modules that comply with stringent safety and quality standards, specifically UL (Underwriters Laboratories) certification. Consumers and developers are often willing to pay a premium for modules that qualify for tax credits and are perceived as higher quality.

Latin America and the Caribbean

In this region, market growth is driven more by fundamental economics and necessity. Abundant solar irradiation, coupled with rising electricity costs and often unstable grid infrastructure, makes solar a compelling investment. The primary drivers are energy independence and long-term cost savings. Consequently, the market is often more price-sensitive and primarily adheres to IEC (International Electrotechnical Commission) standards, which are the global benchmark for solar module performance and safety.

Why Mexico is a Unique Strategic Hub

Mexico’s geographic location and economic structure offer a unique set of advantages for an aspiring solar module manufacturer. It acts as a bridge, not just geographically, but also economically and logistically.

Geographic and Logistic Supremacy

Positioned between the world’s largest solar market (the U.S.) and the rapidly growing markets of Latin America, Mexico offers unparalleled logistical advantages. The United States-Mexico-Canada Agreement (USMCA) facilitates tariff-free trade, streamlining access to the U.S. market.

Furthermore, its extensive coastlines with major ports on both the Pacific and Atlantic oceans provide efficient maritime routes to South America, the Caribbean, and even Europe. Compared to shipments from Asia, shipping times to major U.S. distribution centers are measured in days, not weeks. This dramatically reduces inventory costs and improves responsiveness to market demand.

A Favorable Business Environment

Mexico has a long and successful history as a manufacturing powerhouse, particularly in the automotive and electronics industries. This has cultivated a highly skilled and technically proficient workforce accustomed to complex assembly and quality control processes. The country’s industrial infrastructure is well-developed, and operational costs, including labor and facilities, are significantly lower than in the United States or Canada. This combination of skill and cost-efficiency creates a powerful competitive advantage.

A Strong Domestic Foundation

Beyond its export potential, Mexico itself is a substantial and growing market for solar energy. With high solar irradiation across the country, both residential and industrial demand are on the rise. A new manufacturing facility can establish a strong initial foothold by serving this domestic market, generating revenue and refining processes before scaling up its export operations.

The Core Challenge: Navigating Dual Certification Standards

The single greatest technical challenge for a Pan-American manufacturing strategy is producing modules that meet two different regulatory standards: UL for the U.S. and Canada, and IEC for Latin America and most of the rest of the world.

Understanding UL vs. IEC

While both are standards for safety and performance, they have different focuses and require distinct materials and design considerations.

-

IEC (International Electrotechnical Commission): This is the globally recognized standard. It focuses heavily on the performance, quality, and long-term reliability of a solar module.

-

UL (Underwriters Laboratories): This standard is mandatory for the U.S. and Canadian markets. While it also covers performance, its primary emphasis is on electrical safety and fire resistance, often requiring different materials for components like junction boxes and backsheets.

An investor might incorrectly assume that two separate production lines are needed, doubling capital expenditure and operational complexity. This approach is inefficient and often financially prohibitive.

The Solution: A Flexible, Turnkey Production Line

The modern, strategic solution is to design a single, flexible production line capable of producing modules for both standards. This requires deep engineering expertise to create a system that can switch between different bills of materials (BOMs) and process parameters with minimal downtime.

Experience from turnkey projects, such as those engineered by European solar PV equipment provider, shows that a successful dual-certification line includes:

-

Adaptable Automation: Machines, such as stringers and laminators, that can be quickly reconfigured for different cell sizes, module layouts, and material thicknesses.

-

Integrated Quality Control: Automated inspection systems that can verify compliance with either UL or IEC specifications during the production process.

-

Streamlined Material Handling: A logistics system that ensures the correct, certified components are delivered to the line for each production run.

This approach allows a manufacturer to pivot production based on market demand. For example, you can dedicate 70% of capacity to UL-certified modules for a large U.S. order one month, then switch to 60% IEC-certified modules the next to fulfill contracts in Brazil or Colombia. A turnkey solar module production line is engineered from the outset to handle this level of complexity efficiently.

Investment Profile: What to Expect for a Mexican Solar Hub

Entering the manufacturing space requires a clear understanding of the financial and operational commitments. While every project is unique, a typical 50-200 MW facility in Mexico brings key figures into focus.

The initial investment for a modern, automated production line of this capacity generally falls within a specific range, influenced by the level of automation and technology choices. A comprehensive breakdown of the solar panel manufacturing plant cost provides a detailed overview for business planning.

-

Facility Size: A 50-200 MW factory typically requires a building of approximately 5,000 to 10,000 square meters to accommodate the production line, warehousing, and storage.

-

Workforce: A semi-automated line of this size can be operated efficiently with a team of 40 to 80 employees per shift, including technicians, operators, and quality assurance staff.

-

Timeline: With a clear plan and experienced partners, a turnkey factory can be fully operational in under 12 months, from initial planning to the first certified module coming off the line.

Frequently Asked Questions (FAQ)

What are the primary differences between UL and IEC certifications?

In simple business terms, think of IEC as a global ‘performance and quality’ passport and UL as a mandatory ‘safety visa’ for the U.S. and Canada. UL places a stronger emphasis on fire safety and electrical shock prevention, which can dictate the use of specific, often more expensive, materials.

Can a single production line truly produce modules for both standards?

Yes, absolutely. This is a core competency of modern production line engineering. The key is designing the line for flexibility from the beginning, allowing for quick changes in materials and machine settings. It is far more cost-effective than running two separate lines.

What is the typical timeframe for establishing a factory in Mexico?

For a turnkey project managed by an experienced partner, a timeline of 10 to 14 months is realistic. This includes site selection, facility preparation, equipment installation and commissioning, and staff training.

How does the USMCA benefit a solar manufacturer in Mexico?

The USMCA allows goods manufactured in Mexico to be sold in the U.S. and Canada without tariffs, provided they meet rules of origin requirements. This provides a significant cost advantage over modules imported from Asia, which are often subject to tariffs.

Conclusion: Your Strategic Next Steps

Establishing a solar module factory in Mexico is more than just a cost-saving measure; it is a strategic decision to build a resilient, agile manufacturing hub for the entire American continent. By leveraging Mexico’s logistical advantages and investing in a production line engineered for dual-standard (UL and IEC) flexibility, an entrepreneur can effectively capture demand from two distinct, high-growth markets.

This approach transforms a complex manufacturing challenge into a powerful competitive advantage, positioning your business for long-term success in the Western Hemisphere. For those ready to explore this path further, pvknowhow.com provides structured e-courses and expert resources to guide you through each stage of the planning and implementation process.

Get the Pan-American Solar Distribution Case Study (PDF)

Author: This case study was prepared by the

turnkey solar module production specialists at J.V.G. Technology GmbH

It is based on real data and consulting experience from J.v.G. projects

worldwide, including installations ranging from 20 MW to 500 MW capacity.