Disclaimer: This case study represents a composite example derived from real-world

consulting work by J.v.G. Technology GmbH in solar module production and factory optimization. All data points are realistic but simplified for clarity and educational purposes.

For investors eyeing the booming US solar market, the landscape is both compelling and complex. While the US Inflation Reduction Act (IRA) has created powerful incentives for domestic manufacturing, business leaders often face significant hurdles. These include high labor costs and prolonged permitting timelines when establishing production facilities within the United States.

This reality has led many to explore a strategic alternative just across the southern border: establishing a solar factory in Mexico.

This guide outlines how entrepreneurs and established companies can leverage Mexico’s Maquiladora (IMMEX) program to build a cost-effective, efficient manufacturing operation designed for tariff-free export to the US market. It provides a clear blueprint for navigating the legal, financial, and operational steps involved.

The Strategic Advantage of Nearshoring Solar Production to Mexico

Nearshoring—the practice of transferring business operations to a nearby country—has become a cornerstone of modern supply chain strategy. For solar manufacturing aimed at the US market, Mexico offers a unique combination of geographic proximity, favorable trade agreements, and a mature industrial ecosystem.

The core challenge for any US-focused solar business is balancing production costs with logistical efficiency. Sourcing from Asia, long the industry standard, involves significant shipping times, vulnerability to geopolitical tensions, and potential tariffs.

Mexico offers a direct solution to these challenges:

-

Reduced Logistical Complexity: Key manufacturing hubs in northern Mexico, such as Tijuana, Juarez, and Monterrey, are just a day’s drive from major US distribution centers. This drastically cuts shipping times, lowers inventory carrying costs, and allows for a more agile response to market demand.

-

Favorable Trade Environment: The United States-Mexico-Canada Agreement (USMCA) allows goods manufactured in North America to access the US market tariff-free, provided they meet specific ‘rules of origin.’ This is a critical advantage that avoids trade barriers sometimes placed on products from other regions.

-

Competitive Cost Structure: The financial case is strong. Data indicates that average manufacturing labor costs in Mexico can be up to 80% lower than in the United States, without compromising on a skilled and available workforce.

Understanding the IMMEX (Maquiladora) Program

At the heart of Mexico’s manufacturing appeal is the IMMEX program, formally known as the Decreto para el Fomento de la Industria Manufacturera, Maquiladora y de Servicios de Exportación. Simply put, this government initiative allows foreign companies to establish manufacturing facilities in Mexico under a highly favorable tax and customs framework.

The primary benefits for a solar module manufacturer include:

-

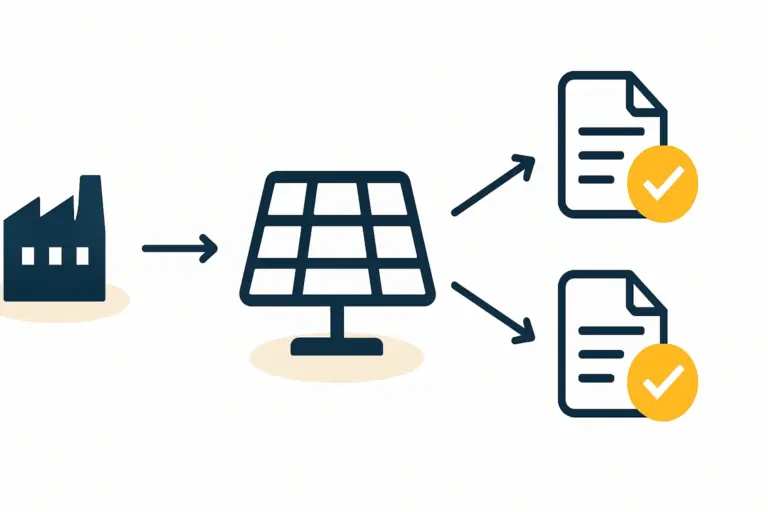

Duty-Free Temporary Imports: Under IMMEX, a company can import machinery, equipment, components, and raw materials into Mexico without paying import duties or value-added tax (VAT). These goods can remain in the country for a set period (typically 18 months for raw materials) as long as the final assembled products are exported.

-

VAT Exemption: The standard 16% VAT is effectively waived for the temporary importation of goods used in the manufacturing process. This significantly improves cash flow during the setup and operational phases.

-

Streamlined Customs Procedures: The program facilitates expedited customs processing for both the import of materials and the export of finished solar modules.

To qualify, a company must demonstrate to the Mexican Secretariat of Economy that its operations will be primarily for export. This typically requires that over $500,000 USD in goods are exported annually or that exports account for at least 10% of total sales.

The Business Case: Financial and Operational Benefits

A solar factory operating under the IMMEX program is not just a legal structure; it is a competitive business model. Beyond the direct tax and tariff savings, the operational advantages are substantial. Investors can access world-class industrial parks with reliable utilities, robust infrastructure, and a deep pool of experienced manufacturing talent.

This combination of cost efficiency and logistical superiority allows a business to produce high-quality solar modules that can compete effectively in the US market while maintaining healthier profit margins.

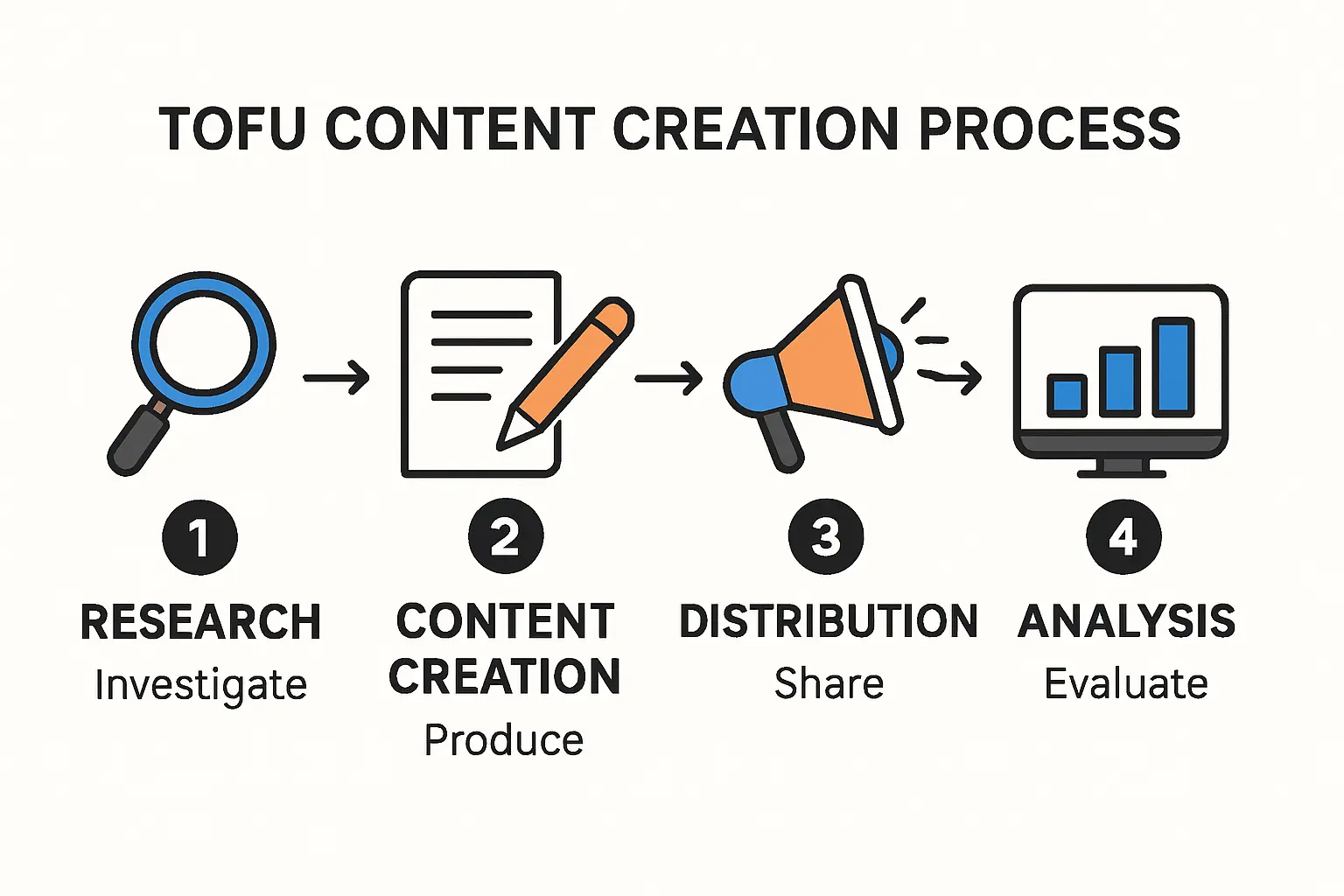

A Step-by-Step Project Timeline for Your IMMEX Solar Factory

Establishing a manufacturing plant in a new country requires a structured, phased approach. Based on experience from turnkey projects, a typical timeline from initial planning to commercial production spans approximately 12 months.

Phase 1: Feasibility and Corporate Structure (Months 1-3)

The foundation for a successful project is meticulous planning. This initial phase focuses on critical due diligence and legal groundwork.

-

Site Selection: Analyzing different industrial zones in Mexico based on logistics, labor availability, and infrastructure.

-

Legal Incorporation: Establishing a Mexican legal entity, most commonly an S.A. de C.V.

-

IMMEX Application: Preparing and submitting the IMMEX program application. This requires a comprehensive business plan detailing production forecasts, machinery lists, and sourcing plans.

Phase 2: Facility Preparation and Line Procurement (Months 4-6)

Once the legal framework is in place, the focus shifts to physical assets and equipment.

-

Building Acquisition: Leasing or purchasing a suitable industrial building and preparing it for the production line (e.g., electrical, HVAC, compressed air systems).

-

Equipment Specification: Finalizing the bill of materials for all solar panel manufacturing equipment with a turnkey provider.

-

Procurement: Placing orders for long-lead-time items such as laminators, stringers, and testers.

Phase 3: Installation and Commissioning (Months 7-9)

This technical implementation phase is where the factory truly comes to life.

-

Equipment Importation: All machinery and equipment arrive at a Mexican port and are imported under the IMMEX program’s temporary, duty-free provisions.

-

Turnkey Installation: An experienced engineering partner manages the installation, setup, and commissioning of the entire production line.

-

Team Development: Hiring and intensively training local operators, engineers, and quality control personnel.

Phase 4: Ramp-Up and Certification (Months 10-12)

The final stage focuses on achieving operational excellence and market readiness.

-

Process Optimization: Conducting initial production runs to calibrate machinery, optimize workflows, and ensure quality standards are met.

-

Product Certification: Manufacturing the first batches of solar modules to obtain the necessary IEC and UL certifications required for the US market.

-

Commercial Production: Launching full-scale production for export.

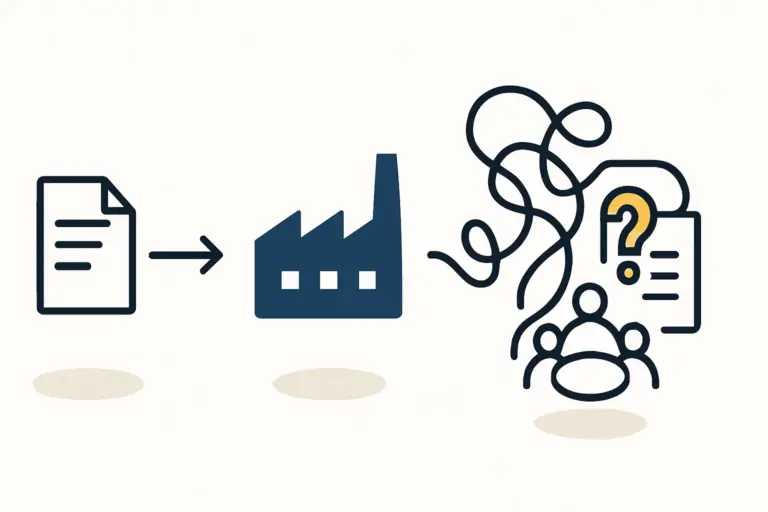

Navigating Compliance and Operational Realities

While the IMMEX program offers immense benefits, it demands strict adherence to Mexican regulations. Success depends on maintaining robust compliance systems.

-

Inventory Control (Annex 24): IMMEX companies must use specialized software to meticulously track all temporarily imported materials from entry to their inclusion in an exported product. Any discrepancies can lead to significant penalties.

-

Customs and Trade Law: Working with experienced Mexican customs brokers and legal counsel is essential for navigating cross-border logistics and ensuring all export documentation is accurate.

-

Labor Regulations: Understanding and complying with Mexican labor laws is vital, as they differ from those in the US, particularly regarding employee benefits and termination procedures.

Building a strong local management team and partnering with reputable legal and accounting firms are not optional—they are critical components of a sustainable, compliant operation.

Frequently Asked Questions (FAQ)

What is the typical solar panel factory cost for an IMMEX setup?

For a semi-automated line with a capacity of 50–100 MW, the investment in machinery typically falls between $3 million and $6 million USD. This estimate excludes the building, working capital, or other soft costs. A detailed financial model is necessary for an accurate projection.

How long does it take to get IMMEX program approval?

The approval process with the Secretariat of Economy generally takes two to four months, provided the application is complete and thoroughly documented.

Are there restrictions on what can be imported temporarily?

The program covers machinery, tools, raw materials, components, and even administrative equipment necessary for the manufacturing operation. Items not directly related to the production process may not qualify.

What are the main differences between setting up in Mexico versus the US?

The primary differences are a significantly lower labor cost base in Mexico and the tax and duty benefits of the IMMEX program. Conversely, setting up in the US may offer direct access to IRA tax credits for production, albeit with higher initial capital and operational expenditures.

How does the USMCA impact solar panels exported from Mexico?

Under the USMCA, solar panels manufactured in Mexico can enter the US market duty-free if they meet the ‘rules of origin’ criteria, which stipulate that a certain percentage of the product’s value must originate from North America. This provides a stable and predictable trade framework.

Executing a solar factory project in Mexico is a complex but entirely manageable undertaking. By leveraging the well-established IMMEX program and partnering with experienced technical consultants, investors can build a powerful manufacturing base to serve the North American market. This strategic approach offers a clear path to producing high-quality solar modules at a competitive price point, positioning your business for long-term success.

Download the IMMEX Solar Factory Case Study (PDF)

Author: This case study was prepared by the

turnkey solar module production specialists at J.V.G. Technology GmbH

It is based on real data and consulting experience from J.v.G. projects

worldwide, including installations ranging from 20 MW to 500 MW capacity.