Disclaimer: This case study represents a composite example derived from real-world

consulting work by J.v.G. Technology GmbH in solar module production and factory optimization. All data points are realistic but simplified for clarity and educational purposes.

Oman’s strategic Vision 2040 is more than a document—it’s a roadmap for profound economic transformation. Central to this vision is a decisive shift towards renewable energy, with targets of 20% of electricity from renewables by 2030 and 39% by 2040. This ambition is backed by a pipeline of giga-scale solar projects, creating one of the most compelling investment environments for solar energy in the Middle East.

For discerning entrepreneurs and established business leaders, this presents a unique opening. The opportunity lies not just in developing solar farms, but in building the industrial backbone that supplies them. Establishing a local solar module manufacturing facility to serve these utility-scale projects is a strategic move that aligns directly with national development goals. This article outlines a complete investment model for a specialized turnkey factory in Oman, focusing on the high-efficiency bifacial technology best suited to the region’s unique environment.

The Strategic Imperative: Why Local Manufacturing in Oman Makes Sense

The demand for solar modules in Oman is set to grow exponentially, driven not by speculation but by government-mandated, large-scale projects that require a stable and reliable supply chain.

Aligning with National Vision and Project Pipelines

Oman’s commitment to renewable energy is concrete. The Oman Power and Water Procurement Company (OPWP) is actively tendering massive projects, including the 500 MW Ibri II Solar Park, which is already operational, the 1 GW combined capacity Manah I & II plants, and a planned 1 GW solar park in the Al Wusta Governorate.

Meeting the module requirements for a single 500 MW project involves procuring and transporting over one million solar panels. A local manufacturing presence offers significant advantages:

- Supply Chain Security: Local manufacturing insulates projects from international shipping disruptions and tariff volatility.

- Reduced Logistical Complexity: It eliminates the high costs and intricate coordination of importing vast quantities of fragile modules.

- In-Country Value (ICV): Local production directly supports Oman’s ICV program by creating skilled jobs and fostering a domestic technology ecosystem.

The Economic Case for Domestic Production

For project developers, a local module supplier is a powerful de-risking tool. The ability to source modules from an in-country facility with transparent production schedules enhances project bankability.

This creates a clear path for a new manufacturer to secure long-term offtake agreements before the factory is even built. These agreements form the financial bedrock of the investment by ensuring predictable revenue streams. When future sales are secured with major utility-scale developers, the investment needed for a solar panel factory becomes far more attractive to financiers.

Technology Selection: Why Bifacial DESERT+ Modules Are Critical for Oman

Success in the Omani market hinges on producing a product specifically engineered for its demanding environmental conditions. While standard modules will underperform, specialized bifacial modules will excel.

Understanding Bifacial Technology in a Desert Environment

A bifacial solar module is designed to capture sunlight from both its front and rear sides. The front side captures direct sunlight, while the rear side absorbs light reflected from the ground—a phenomenon known as ‘albedo.’

The light-colored sand of the Omani desert has a high albedo (typically 30-40%), reflecting a significant amount of sunlight and making the region one of the world’s best environments for bifacial technology. In these conditions, a bifacial module can generate 10% to 25% more electricity than a traditional monofacial module of the same size. This ‘bifacial gain,’ when applied to a utility-scale project, translates directly into millions of dollars in additional revenue over the project’s lifetime.

The ‘DESERT+’ Specification: Engineering for Harsh Conditions

Operating reliably for 25-30 years in an environment with extreme heat, high UV radiation, and abrasive sand requires more than standard bifacial cells. A ‘DESERT+’ module specification incorporates several critical engineering features:

- High Thermal Stability: Using materials and cell technologies that minimize power loss (degradation) at high operating temperatures.

- Robust Construction: Employing stronger frames and thicker glass to withstand potential wind loads and handling during large-scale installation.

- Abrasion-Resistant Coatings: Applying special coatings to the glass surface to protect against the ‘sandblasting’ effect of wind-blown particles.

- Optimized Encapsulants: Using materials that resist yellowing and degradation from intense UV exposure.

Producing modules to this standard requires specialized manufacturing equipment—machines capable of handling advanced materials and maintaining the highest levels of quality control.

The Turnkey Factory Model: A Phased Approach to Market Entry

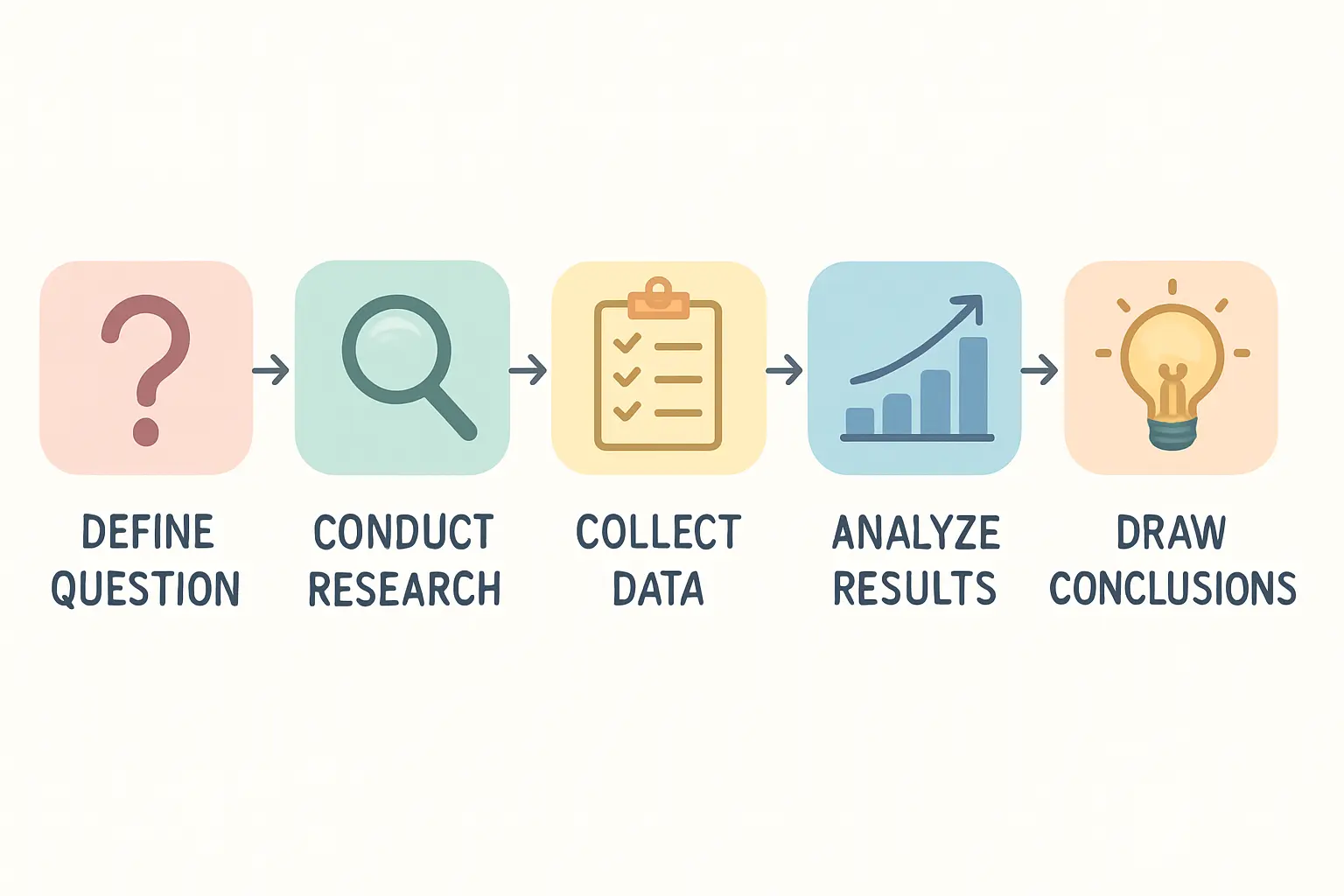

A turnkey approach provides a structured, managed pathway to full-scale production—a valuable advantage for investors new to the solar industry. The process is best understood in three distinct phases.

Phase 1: Feasibility and Securing Offtake

The most critical first step isn’t factory construction, but securing commercial viability. This involves engaging with the key utility-scale developers active in Oman. A credible proposal, backed by a solid technical plan and financial model, can lead to a letter of intent or a conditional offtake agreement. Experience from turnkey projects shows this commercial foundation is paramount, as it serves as the primary validation of the business case.

Phase 2: Factory Planning and Financial Modeling

With a potential offtaker identified, the next step is detailed planning. A semi-automated production line with an annual capacity of 100-200 MW is a common starting point for the utility market. The initial capital expenditure for such a facility typically falls between USD 8–15 million. This phase involves:

- Developing a detailed business plan and financial projections.

- Designing the factory layout for optimal material flow.

- Finalizing the bill of materials (BOM) and sourcing strategy.

- Securing project financing, a process made far simpler with an offtake agreement in place.

A turnkey solar production line partner manages the technical specifications and equipment integration, ensuring all components work together seamlessly.

Phase 3: Implementation and Commissioning

This is the execution phase, where the factory is built and brought online. A turnkey partner takes responsibility for the entire process:

- Procurement and logistics for all manufacturing equipment.

- On-site installation and commissioning of the production line.

- Training of local operators and technicians.

- Overseeing the initial production ramp-up and quality certification processes.

From the start of construction to the production of the first certified module, a well-managed turnkey project of this scale can be completed within 12 to 18 months.

Navigating the Omani Regulatory and Business Landscape

While the opportunity is significant, success requires an understanding of the local business environment. Setting up a factory within one of Oman’s industrial free zones, such as Sohar or Duqm, can offer substantial benefits, including tax exemptions and simplified import/export procedures.

Also essential is an understanding of the role of OPWP as the country’s single buyer of electricity from independent power producers. The long-term Power Purchase Agreements (PPAs) that OPWP signs with solar farm developers provide the financial security that ultimately flows down to module suppliers. Engaging with a strong local partner can be invaluable for navigating administrative and regulatory processes.

Frequently Asked Questions (FAQ)

What is the minimum viable factory size for this model?

For supplying utility-scale projects, a starting capacity of 100 MW per year is generally considered a viable entry point. This allows for economies of scale in raw material purchasing and provides enough output to be a significant supplier for a large project.

How many employees are needed for a 100 MW factory?

A modern, semi-automated 100 MW line typically requires approximately 50-70 personnel across production, quality control, maintenance, and administration.

What are the primary raw materials, and where are they sourced?

The key materials are solar cells, glass, aluminum frames, encapsulant (EVA or POE), and backsheets. While some materials may be sourced regionally, high-efficiency solar cells are predominantly sourced from leading manufacturers in Asia.

What certifications are required for modules to be used in Omani utility projects?

Modules must meet international standards from the International Electrotechnical Commission (IEC), such as IEC 61215 (design qualification) and IEC 61730 (safety qualification). Additional certifications for desert conditions (e.g., sand and dust testing) are also highly recommended.

How does a turnkey partner de-risk the investment?

A turnkey partner de-risks the project through their proven expertise. They guarantee that the factory will be delivered on time, within budget, and capable of producing modules to the required quality and certification standards. This eliminates technical and operational uncertainties for the investor.

Conclusion: Your Next Steps in a High-Growth Market

The combination of Oman’s clear government vision, a robust pipeline of utility-scale projects, and ideal environmental conditions for bifacial technology creates a powerful and timely investment opportunity. This strategic model—establishing a local factory to supply these projects—offers a clear, de-risked path to market entry.

Success hinges on a methodical approach: securing offtake agreements first, selecting technology engineered for the local environment, and executing the factory build-out with an experienced turnkey partner. For investors ready to explore this opportunity further, the path forward begins with a detailed feasibility study and a deeper understanding of the solar manufacturing process.

Download the Turnkey Bifacial Module Manufacturing Case Study [PDF]

Author: This case study was prepared by the

turnkey solar module production specialists at J.V.G. Technology GmbH

It is based on real data and consulting experience from J.v.G. projects

worldwide, including installations ranging from 20 MW to 500 MW capacity.