A significant opportunity is emerging for investors in Turkey. The government’s Renewable Energy Resources Support Mechanism (YEKDEM) provides attractive incentives for solar energy projects, but with a crucial condition: the most favorable feed-in tariffs are reserved for projects using domestically manufactured components.

This presents a clear business challenge: how does one enter the solar manufacturing industry to capture this demand, especially without a deep technical background in photovoltaics?

This project assessment outlines a detailed plan for establishing a 25 MW solar module factory in Anatolia. It explores how a turnkey approach can align the factory’s setup, technology, and output with the specific requirements of the YEKDEM program, creating a viable and profitable business focused on the domestic market.

Understanding the Opportunity: Turkey’s YEKDEM Program

The Turkish government’s YEKDEM program is designed to accelerate the country’s transition to renewable energy. It is a feed-in tariff system that guarantees a fixed price for electricity generated from sources like solar for a set period. This guarantee reduces investment risk for solar farm developers and makes financing more accessible.

A key feature of the program, however, is its emphasis on ‘local content.’ Solar power plants that use components manufactured in Turkey—such as solar modules, steel structures, and inverters—receive a significant premium on the guaranteed electricity price. This incentive structure was designed to stimulate a domestic renewable energy industry, reduce reliance on imports, and create local employment.

For an entrepreneur, this policy transforms the competitive landscape. Instead of competing on price alone with global manufacturing giants, a local factory can offer a product that unlocks superior financial returns for its customers—the solar farm developers. The primary business driver is not just producing a solar module, but producing a YEKDEM-compliant solar module.

Strategic Factory Design for YEKDEM Compliance

Meeting these specific market needs requires a carefully planned factory. The entire operation, from production capacity to the choice of technology, must be optimized for the Turkish domestic market.

Sizing the Production Line: The 25 MW Sweet Spot

For an initial entry into the market, a 25 MW annual production capacity is a strategic choice. This size offers an ideal balance:

-

Manageable Investment: It requires a substantial but manageable capital outlay for many entrepreneurs and investment groups, avoiding the immense financial requirements of a gigawatt-scale facility.

-

Operational Efficiency: A 25 MW line is large enough to benefit from economies of scale in purchasing raw materials and can be operated efficiently with a workforce of approximately 25 to 35 employees.

Ready to make big Profits?

The solar Industry is Booming

WE HELP NEWCOMERS to the solar industry start their own solar module production line. Customers can make BIG PROFITS by selling modules and finding investors, without wasting money and time on things they don't need!

-

Market Alignment: This output level corresponds well with the scale of many utility and commercial solar projects developed under the YEKDEM framework, ensuring a consistent demand pipeline.

Typically, such a facility requires around 1,500 to 2,000 square meters of floor space, making it feasible to establish in existing industrial zones in regions like Anatolia.

Aligning Technology with Market Demand

The choice of technology is critical. The goal is not to chase the highest possible laboratory efficiency, but to produce a reliable, certified, and cost-effective module that meets the technical and financial expectations of Turkish project developers.

For this market, producing modules based on PERC (Passivated Emitter and Rear Cell) technology is a prudent strategy. PERC is a mature, highly reliable technology that offers excellent efficiency and performance. Using M10 (182 mm) half-cut monocrystalline cells is a modern standard that ensures competitive power output and durability.

The final product would be a high-performance module, fully certified to IEC standards (such as IEC 61215 and IEC 61730), that local developers can confidently use in their projects to secure the YEKDEM local content bonus. Prioritizing quality assurance throughout the process of setting up a complete solar manufacturing business is essential for building a strong domestic brand.

The Turnkey Approach: From Planning to Production

For an investor without prior experience in photovoltaics, a turnkey project structure provides a clear, manageable path. A turnkey solar manufacturing line partner manages the entire technical implementation, allowing the owner to focus on business development, finance, and local commercial relationships.

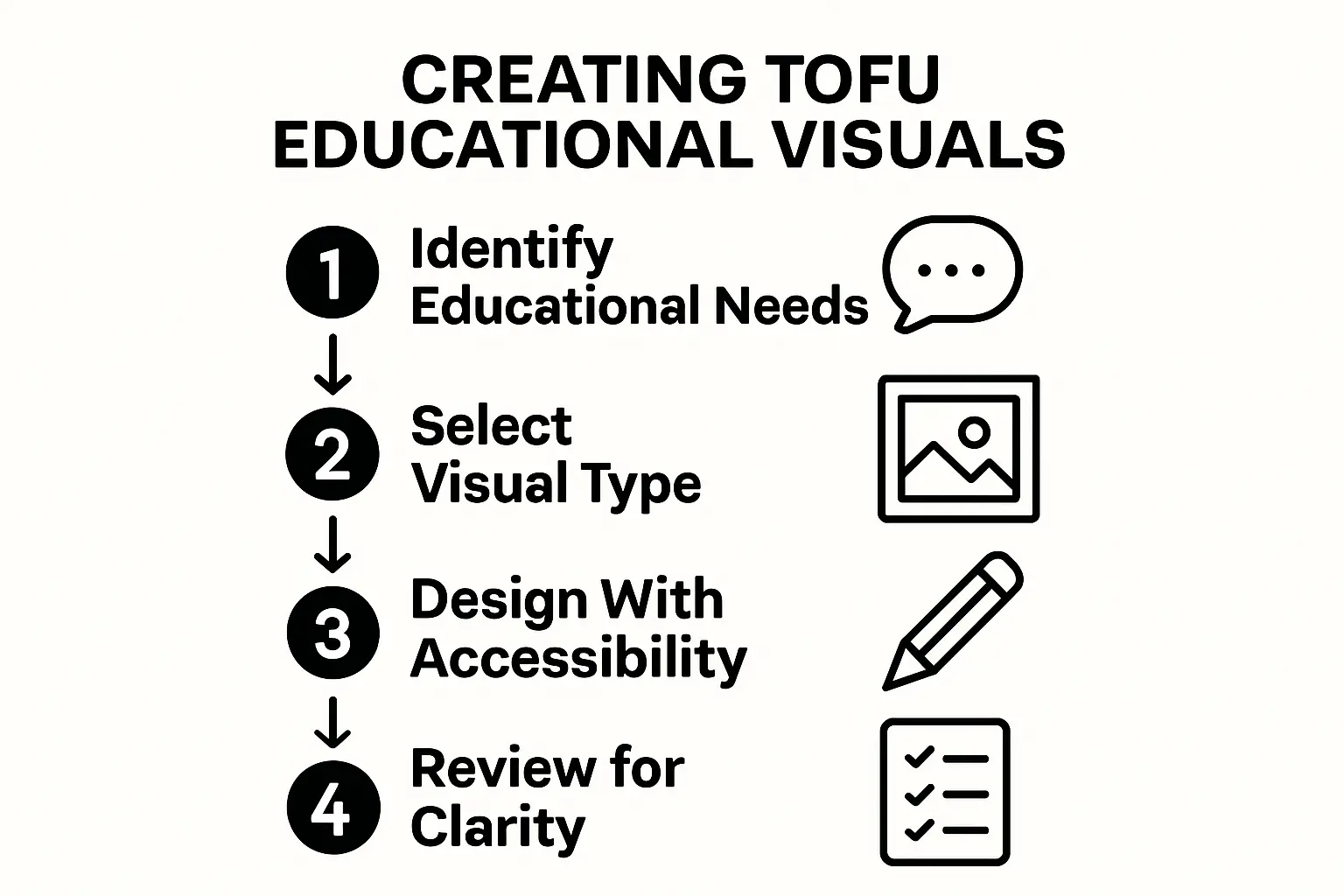

Experience with J.v.G. turnkey projects shows the process typically breaks down into distinct phases:

- Feasibility & Planning: Analyzing the business case, designing the factory layout, and defining the precise bill of materials.

- Equipment Procurement: Sourcing, ordering, and managing the logistics for all necessary machinery, from the stringer to the final laminator and tester.

- Installation & Commissioning: Managing the on-site installation of the production line and ensuring every machine is calibrated and functioning correctly.

- Training & Ramp-Up: Providing comprehensive training to the local workforce on machine operation, quality control, and maintenance protocols to ensure a smooth transition to full production.

This structured approach significantly de-risks the project for a new market entrant.

Navigating Local Challenges and Opportunities in Anatolia

Locating the factory in Central Anatolia offers several advantages, including access to industrial land, a capable workforce, and logistical corridors to major cities across Turkey. However, success requires addressing local conditions head-on.

Supply Chain and Logistics

While the modules are assembled locally, key raw materials like solar cells, encapsulants (EVA), and specialized glass are often sourced internationally. A critical early task is establishing a robust supply chain. This involves building relationships with global suppliers while developing an efficient logistics plan for importing materials and distributing finished modules to project sites within Turkey.

Building a Skilled Workforce

The transfer of knowledge is a key asset of a turnkey partnership. The local workforce, while skilled in general manufacturing, will require specialized training. A comprehensive program covering machine operation, quality inspection criteria, and safety procedures is essential. This investment in human capital ensures the factory can consistently produce high-quality modules that uphold the brand’s reputation and meet certification standards.

Frequently Asked Questions (FAQ)

What is the typical timeframe to build a 25 MW factory?

From signing the contract to producing the first certified module, a turnkey project of this scale typically takes between 9 and 12 months. This includes equipment manufacturing, shipping, installation, and personnel training.

Is a technical background required to start this business?

No. An investor needs a strong business and financial background. The technical expertise for factory design, equipment selection, and process optimization is provided by the turnkey engineering partner, such as J.v.G. Technology GmbH. The pvknowhow.com platform provides structured e-courses to help with the initial planning phase.

How does a local factory compete with large international manufacturers?

A local factory competes on strategic value, not just on unit cost. It offers its customers—the solar farm developers—a product that qualifies for valuable government incentives (the YEKDEM bonus). This local-for-local advantage is a powerful market differentiator that large importers cannot offer.

What are the main raw materials needed for production?

The primary materials include monocrystalline solar cells, tempered front glass, EVA or POE encapsulant film, a polymer backsheet, and extruded aluminum frames for the finished module.

What are the critical certifications for the solar modules?

The modules must be certified according to international standards, primarily IEC 61215 (design qualification and type approval) and IEC 61730 (photovoltaic module safety qualification). These certifications are globally recognized and are a prerequisite for bankability and use in large-scale projects.

Conclusion: The Path Forward for Investors

Government programs like Turkey’s YEKDEM create powerful, protected opportunities for investors looking to establish local manufacturing operations. The success of a 25 MW solar factory in Anatolia hinges on a strategy built around serving the specific needs of this domestic market. By aligning production capacity, technology, and quality with the requirements of the incentive program, an investor can build a defensible and profitable business.

For entrepreneurs in other emerging solar markets, this model serves as a valuable blueprint. Where similar local content policies exist, the strategy of building a moderately-sized, high-quality manufacturing facility can provide a direct and effective path to market leadership. The key is to combine local business acumen with the deep technical expertise of an experienced engineering partner.