Disclaimer: This case study represents a composite example derived from real-world

consulting work by J.v.G. Technology GmbH in solar module production and factory optimization. All data points are realistic but simplified for clarity and educational purposes.

Lebanon’s current economic landscape presents a striking paradox. While facing a severe energy crisis, the country is also witnessing an unprecedented surge in demand for reliable power, creating a significant opportunity for entrepreneurs in the solar industry.

However, transitioning from importing solar panels to manufacturing them locally requires navigating a complex maze of regulations, quality standards, and institutional requirements. Success isn’t just about producing a solar module; it’s about producing a certified one that earns market trust and opens doors to broader opportunities.

This article provides a structured framework for business professionals looking to establish a solar module factory in Lebanon. It outlines the key regulatory bodies, details the certifications essential for market access, and offers a step-by-step process to ensure compliance and build a sustainable enterprise.This guidance is informed by decades of international engineering experience, including long-standing ties to the Lebanese industrial sector.

The Lebanese Solar Landscape: A Market Defined by Necessity and Opportunity

The demand for solar energy in Lebanon is not driven by environmental policy alone but by acute necessity. Persistent grid instability and the high cost of private generator power have made solar solutions an essential investment for businesses and households alike. This has created a robust market that is now mature enough to support local manufacturing.

Establishing a local production facility offers distinct competitive advantages. It reduces reliance on complex import logistics, creates local employment, and provides greater control over product quality. The most critical advantage, however, is the ability to build a trusted local brand, which begins with understanding and adhering to the national regulatory framework.

Key Regulatory Pillars for Solar Manufacturing in Lebanon

Understanding the roles of three key institutions is fundamental for any entrepreneur entering this sector. These organizations form the regulatory and quality infrastructure for renewable energy in the country.

-

Lebanese Center for Energy Conservation (LCEC): Operating under the Ministry of Energy and Water, the LCEC is the national energy agency. Its role is primarily strategic—promoting renewable energy, developing national action plans, and facilitating large-scale projects. While not a direct certification body for manufacturers, its guidance and market initiatives shape the industry.

-

LIBNOR (Lebanese Standards Institution): This is the official body responsible for setting and publishing national standards for all products and services, including solar modules. LIBNOR manages the Lebanese quality mark (NL mark), a crucial differentiator in the market. Compliance with LIBNOR standards is often a prerequisite for participating in public tenders and large commercial projects.

-

Industrial Research Institute (IRI): The IRI serves as a key technical arm for the industry. As a certified testing laboratory, it verifies that products, including solar modules, meet the required standards set by LIBNOR. A positive test report from the IRI is an essential step in the certification process.

Achieving Certification: The Cornerstone of a Sustainable Business

In a market flooded with imported products of varying quality, certification is the most effective tool for building consumer confidence and ensuring long-term business viability. It demonstrates a commitment to safety, performance, and durability. The certification path in Lebanon is twofold, involving both international benchmarks and a national quality mark.

International Standards: The Global Benchmark (IEC)

Before seeking national certification, a manufacturer must ensure their products meet internationally recognized standards. For solar modules, the two most critical are:

-

IEC 61215: This standard series tests the design and performance of a solar module. It subjects panels to a range of stress tests—including thermal cycling, humidity and freeze tests, and mechanical load tests—to ensure they can withstand decades of outdoor operation.

-

IEC 61730: This standard focuses on module safety. It covers aspects of construction and testing to protect against mechanical and electrical hazards like electric shock and fire.

Adherence to these standards is non-negotiable for any serious manufacturing operation. A robust system for solar module quality assurance is integrated directly into the production process to ensure every module meets these global requirements.

National Standards: The Lebanese NL Mark

The NL mark, issued by LIBNOR, is the official confirmation that a solar module complies with Lebanese national standards. These standards are typically harmonized with international IEC standards but represent a specific endorsement for the local market. Obtaining the NL mark signals to customers, financiers, and government bodies that your product has been independently tested and verified for quality and safety under the national system.

A Structured Framework for Establishing Your Factory

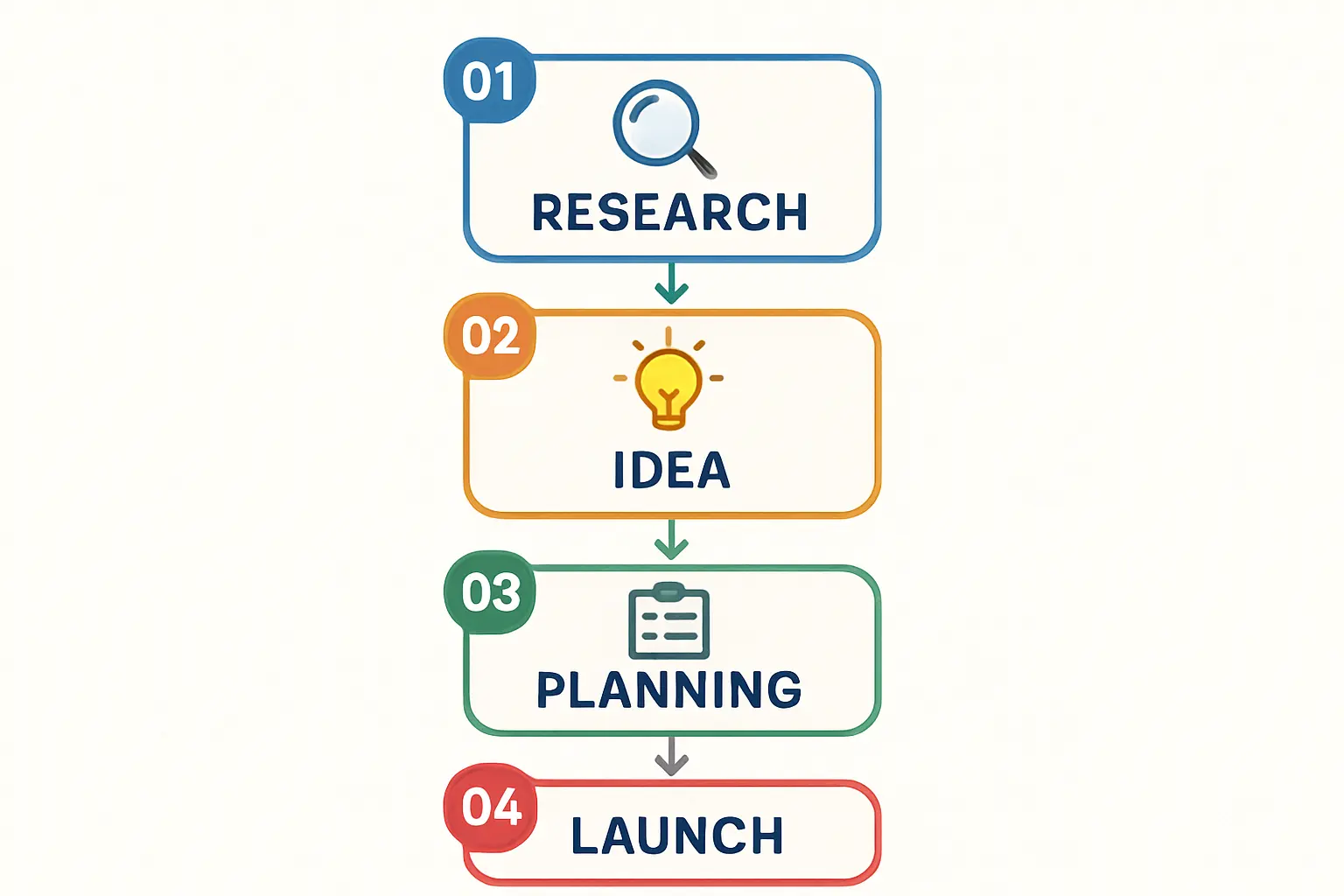

Navigating the legal, technical, and regulatory requirements can seem daunting. A systematic, turnkey approach breaks the process down into manageable phases, ensuring that compliance is integrated from the start. Based on European PV manufacturers’ experience with turnkey projects, a logical pathway includes feasibility, planning, execution, and certification.

Step 1: Legal and Financial Foundation

The first step is establishing the right legal and financial structure.

-

Company Registration: Most industrial ventures in Lebanon are established as either a SARL (limited liability company) or a SAL (joint-stock company), depending on the scale of investment and the number of partners.

-

Investment Incentives: Entrepreneurs should contact the Investment Development Authority of Lebanon (IDAL). IDAL offers a range of incentives for industrial projects, which may include tax exemptions and streamlined administrative procedures.

-

Business Planning: A comprehensive solar panel business plan is essential. This document should detail market analysis, financial projections, and a clear strategy for achieving profitability and compliance.

Step 2: Technical Planning and Design

With the legal framework in place, the focus shifts to the physical factory.

-

Factory Layout: The design of the production facility must be optimized for workflow efficiency, safety, and quality control.

-

Production Line: Selecting the right equipment for a turnkey solar panel production line is critical. The machinery must be capable of consistently producing modules that meet IEC specifications. The entire solar panel manufacturing process, from cell stringing to final lamination, must be designed with quality gates at each stage.

Step 3: Navigating Import and Customs

Since most raw materials—solar cells, glass, EVA encapsulant, backsheets, and aluminum frames—are imported, understanding customs procedures is vital. Industrial projects registered with the Ministry of Industry may be eligible for customs exemptions on raw materials and equipment, significantly reducing initial capital expenditure.

Step 4: The Path to Certification

This phase integrates the results of all previous steps.

-

Internal Quality Control: Establish and document a rigorous quality management system aligned with IEC standards.

-

Sample Production: Manufacture a batch of modules specifically for testing.

-

Third-Party Testing: Submit sample modules to a recognized laboratory like the IRI for testing against IEC and national standards.

-

Application for NL Mark: With a successful test report, submit a formal application to LIBNOR—including all technical documentation and quality control procedures—to obtain the NL mark.

Beyond the Local Market: Export Potential and Regional Leadership

Achieving IEC and NL certification does more than unlock the Lebanese market; it positions a manufacturer as a credible supplier for neighboring countries. A certified, ‘Made in Lebanon’ solar module can be a mark of quality for export to markets such as Syria, Jordan, and Iraq, where demand for reliable energy solutions is also growing. This transforms the business from a local player into a potential regional leader.

Frequently Asked Questions (FAQ)

What is the primary difference between IEC and the NL mark?

IEC standards are internationally developed and globally recognized benchmarks for quality and safety. The NL mark is a national certification from LIBNOR that confirms a product meets Lebanese standards, which are generally based on IEC standards. The NL mark is specific to market access within Lebanon.

How long does the certification process typically take?

Once the factory is operational and producing consistent modules, the formal process of testing and administrative approval can take between 6 and 12 months. Proper preparation and a well-documented quality system can help streamline this timeline.

Can a factory operate without certification in Lebanon?

While it’s technically possible to produce and sell uncertified modules, it is a high-risk business strategy. Uncertified producers are excluded from government tenders, large commercial projects, and export markets. They also struggle to build the long-term consumer trust necessary for sustainable growth.

What are the main raw materials that need to be imported?

The core components are typically imported. These include solar cells, tempered front glass, EVA (ethylene vinyl acetate) encapsulant, polymer backsheets, aluminum frames, and junction boxes with cables.

Conclusion: Building a Compliant and Profitable Solar Enterprise

Establishing a certified solar module factory in Lebanon is a significant undertaking, but it is far from insurmountable. The regulatory landscape, while detailed, is structured and navigable with the right preparation and expert guidance. By focusing on quality from day one and treating certification not as a bureaucratic hurdle but as a strategic asset, entrepreneurs can build a resilient business that addresses a critical national need.

Success in this venture lies in a methodical approach: building a solid business plan, designing an efficient production facility, and integrating international quality standards into every step of the manufacturing process. By doing so, a new manufacturing enterprise can become a trusted local supplier and a powerful contributor to Lebanon’s energy future.

Download the Lebanese Solar Regulation Case Study (PDF)

Author: This case study was prepared by the

turnkey solar module production specialists at J.V.G. Technology GmbH

It is based on real data and consulting experience from J.v.G. projects

worldwide, including installations ranging from 20 MW to 500 MW capacity.