Disclaimer: This case study represents a composite example derived from real-world

consulting work by J.v.G. Technology GmbH in solar module production and factory optimization. All data points are realistic but simplified for clarity and educational purposes.

When exploring solar manufacturing, many entrepreneurs initially focus on broad national policies or labor costs. The most successful ventures, however, hinge on a more granular view: identifying a regional ecosystem where industrial heritage, skilled labor, and forward-thinking policy converge.

For those aiming to produce high-efficiency solar modules, the Indian state of Tamil Nadu makes a compelling, and perhaps unexpected, case. This analysis explores why Tamil Nadu has become a strategic hub for advanced solar manufacturing and how it offers a unique competitive advantage that goes beyond generic incentives. It examines the interplay of its industrial base, talent pool, and specific support for next-generation technologies like TOPCon, creating a framework for investors considering this dynamic market.

The Industrial Powerhouse: Why Tamil Nadu Stands Out

Often called the ‘Detroit of Asia,’ Tamil Nadu’s industrial prowess is not a recent development. The state has a long-established reputation as a center for automotive and electronics manufacturing. This legacy provides the critical foundation for the precision and automation required in solar module manufacturing.

Unlike regions that offer only basic infrastructure, Tamil Nadu provides a mature industrial landscape. This includes:

-

Precision Engineering Culture: A workforce accustomed to the tight tolerances and quality control standards of the automotive and electronics sectors can adapt quickly to the demands of photovoltaic production.

-

Robust Infrastructure: The state is home to major ports like Chennai, Ennore, and Tuticorin, facilitating the import of specialized equipment and the export of finished modules.

-

Established Industrial Zones: Dedicated industrial parks like the Sriperumbudur and Oragadam corridors offer developed land, reliable power, and logistical support, reducing the initial friction of setting up a new facility.

This existing framework means a new solar enterprise is not starting from scratch; it is plugging into a functioning, high-performance industrial machine.

The Three Pillars of Tamil Nadu’s Solar Advantage

The case for Tamil Nadu rests on three interconnected strengths that create a synergistic environment for solar manufacturing, particularly for companies focused on technological leadership.

Pillar 1: A Deep Pool of Skilled Technical Labor

A significant challenge for advanced manufacturing is sourcing qualified personnel. Tamil Nadu has a distinct advantage here due to its concentration of premier educational institutions, most notably the Indian Institute of Technology (IIT) Madras. This, along with a network of polytechnic institutes, ensures a steady supply of engineers, technicians, and skilled operators familiar with sophisticated industrial processes.

Based on experience gained from European PV manufacturers’ turnkey projects in similar regions, access to a skilled local workforce dramatically reduces ramp-up time and long-term operational costs associated with training and expatriate staffing.

Pillar 2: Proactive State Policy and Targeted Incentives

The state government has demonstrated a clear commitment to renewable energy through policies like the Tamil Nadu Solar Energy Policy 2019 and the Industrial Policy 2021. These are not just statements of intent; they provide tangible financial benefits for new investors. Typical incentives include:

-

Capital Subsidies: Direct financial support for investment in plant and machinery.

-

Electricity Tax Exemptions: Reductions or waivers on electricity taxes for a specified period.

-

Stamp Duty Waivers: Full or partial exemption on the stamp duty for land acquisition and registration.

Crucially, these incentives are often structured to favor high-tech and capital-intensive projects. This signals a strategic, state-level interest in attracting manufacturers producing advanced, high-efficiency products, not just those assembling standard modules.

Pillar 3: A Mature and Accessible Supply Chain

Proximity to suppliers is a critical factor in managing costs and ensuring production continuity. Tamil Nadu and its neighboring states host a growing number of suppliers for key module components, including:

- Solar Glass

- Aluminum Frames

- Encapsulants (EVA/POE)

- Junction Boxes

- Backsheets

The ability to source these materials locally reduces logistical complexity, minimizes inventory requirements, and shields the business from the volatility of international shipping costs.

The Technology Leap: Why Advanced Cells Like TOPCon Thrive Here

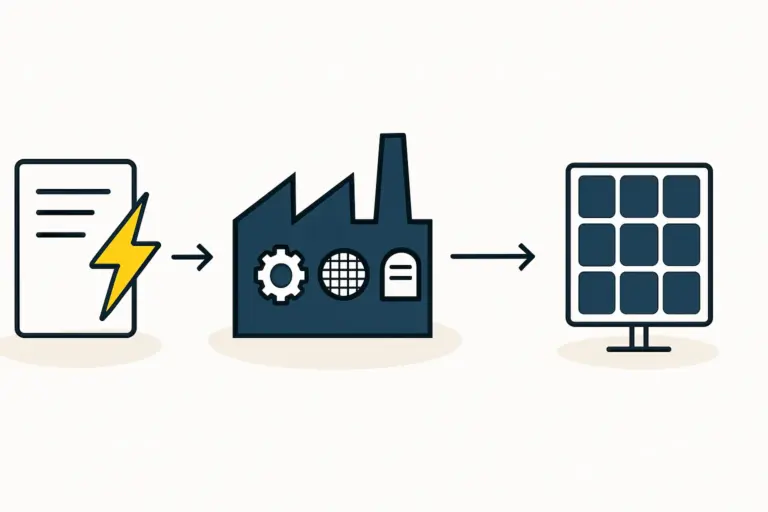

While many regions can support standard PERC module production, Tamil Nadu’s ecosystem is uniquely suited for the next generation of solar technology. The state’s incentives are often more generous for businesses investing in advanced manufacturing processes, such as those required for TOPCon solar cell technology.

TOPCon (Tunnel Oxide Passivated Contact) cells represent a significant efficiency improvement over the industry-standard PERC (Passivated Emitter and Rear Cell) technology. However, their production demands a higher degree of process control, automation, and technical oversight.

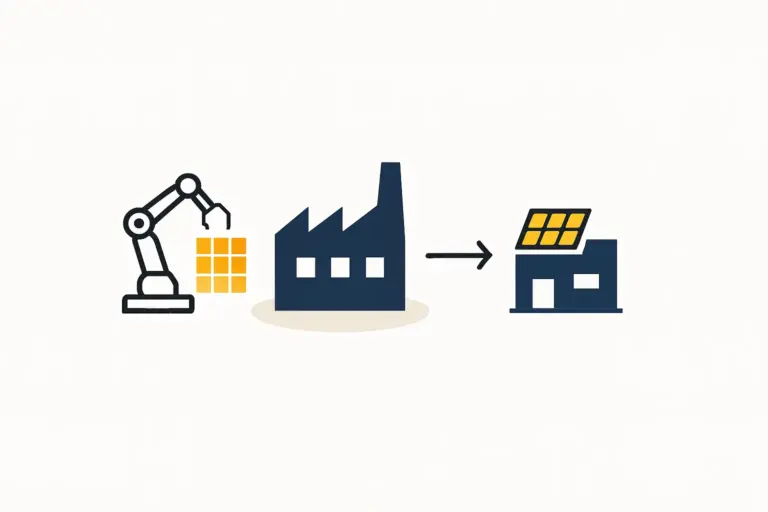

Here, Tamil Nadu’s industrial DNA becomes a decisive advantage. The state’s experience in electronics and precision engineering provides the ideal environment to implement and optimize these more complex manufacturing lines. This allows a new facility to compete on technology and quality, not just on price. A well-planned turnkey solar manufacturing line can be designed from the outset to capitalize on these advanced cell architectures.

Navigating the Local Landscape: From Potential to Production

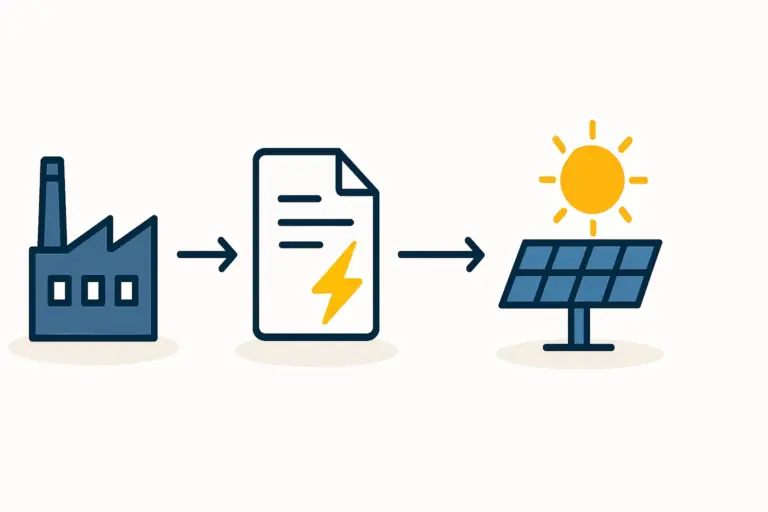

Despite its many advantages, establishing a factory in any new territory presents challenges. Navigating local bureaucracy, land acquisition protocols, and utility connections requires experienced guidance. The process of integrating with local suppliers and ensuring compliance with all state and national regulations is a complex undertaking.

Effective factory planning must account for these on-the-ground realities. This makes support from a consultancy with direct experience in the region essential. An experienced partner can help a new investor navigate these hurdles, manage timelines, and ensure the project moves efficiently from blueprint to full operation. For instance, the EU-based Photovoltaic Manufacturing Solution Partner has supported numerous clients, such as Mr. Goyal from India, in navigating these exact challenges to establish successful manufacturing operations.

Frequently Asked Questions (FAQ)

What is the typical investment for a 50 MW solar module factory in Tamil Nadu?

While costs vary with technology and level of automation, a typical budget for a 50 MW facility using modern equipment would be in the range of USD 5–8 million. This includes machinery, initial setup, and working capital but excludes land and building costs.

How long does it take to establish a factory from planning to production?

With a well-structured plan and experienced partners, a timeline of 10–14 months is realistic. This covers company registration, land acquisition, construction, equipment procurement and installation, and initial commissioning.

Do I need a local partner to set up a business in Tamil Nadu?

While not legally mandatory for 100% foreign direct investment in this sector, having a local presence or an experienced consultancy to manage local interactions is strongly recommended. It significantly simplifies administrative processes and building relationships with suppliers.

What is the primary language for conducting business?

English is widely spoken in business and government circles in Tamil Nadu, making it a very accessible state for international investors. Tamil is the local language, and having staff fluent in it is beneficial for day-to-day operations.

Conclusion: A Strategic Convergence for Solar Pioneers

Tamil Nadu offers more than just a location for a solar factory; it provides a comprehensive industrial ecosystem. For the entrepreneur or business leader looking to enter the market with a technological edge, the convergence of skilled labor, a mature supply chain, and policy support for advanced manufacturing creates a powerful and sustainable competitive advantage.

By understanding and leveraging these unique regional strengths, a new solar module manufacturing facility can be positioned not merely as a production plant, but as a center of technological excellence poised to serve the growing demand for high-efficiency solar energy solutions in India and beyond.

Download the Tamil Nadu Solar Manufacturing Strategic Analysis (PDF)

Author: This case study was prepared by the

turnkey solar module production specialists at J.V.G. Technology GmbH

It is based on real data and consulting experience from J.v.G. projects

worldwide, including installations ranging from 20 MW to 500 MW capacity.