Disclaimer: This case study represents a composite example derived from real-world

consulting work by J.v.G. Technology GmbH in solar module production and factory optimization. All data points are realistic but simplified for clarity and educational purposes.

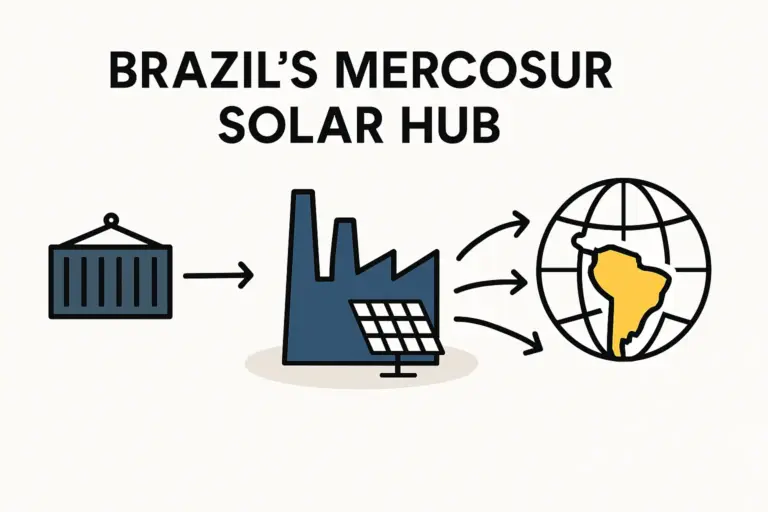

Brazil’s agribusiness is a global powerhouse, accounting for over a quarter of the nation’s GDP. Yet, for many operators—from family-run farms to large-scale cooperatives—unpredictable and rising energy costs are a significant operational challenge. This challenge, however, also creates a substantial investment opportunity: establishing a local solar module factory tailored specifically to the needs of the agricultural sector.

This blueprint outlines a strategic approach for entrepreneurs and investors to capitalize on this opportunity. It explores how a turnkey solar factory can be financed through specific agricultural credit lines, serve the market via farming cooperatives, and be implemented from start to finish using a proven technical framework.

The Untapped Synergy: Solar Energy and Brazilian Agriculture

The connection between solar energy and agriculture is direct and powerful. Consistent energy is essential for irrigation, cooling, processing, and general farm operations. Given Brazil’s high levels of solar irradiation, solar power isn’t just an alternative—it’s an optimal solution for achieving energy independence and cost stability.

A local solar module factory offers distinct advantages over importing panels. It creates a reliable supply chain, allows for product customization, and builds trust within the community. For the agricultural end-user, the benefits are clear:

- Reduced Operational Costs: Lowering dependence on an expensive and sometimes unreliable national grid.

- Energy Independence: Gaining control over a critical input, insulating operations from price hikes and power outages.

- Access to Favorable Financing: Leveraging government incentives designed to promote sustainable agriculture.

- Increased Productivity: Ensuring reliable power for critical systems like solar water pumps for irrigation.

A Strategic Market Entry: Focusing on Farming Cooperatives

Reaching thousands of individual farms is logistically complex. A more effective market approach is to partner with Brazil’s well-established farming cooperatives. These organizations serve as trusted hubs for their members, aggregating demand and facilitating the adoption of new technologies.

By positioning the solar factory as a strategic supplier to these cooperatives, an investor can:

- Access a Concentrated Market: Engage with a single entity that represents hundreds or thousands of end-users.

- Simplify Sales and Distribution: Utilize the cooperative’s existing network to deploy solar solutions efficiently.

- Build Lasting Commercial Relationships: Become an integral technology partner for the region’s agricultural community.

This model elevates the factory from a simple component manufacturer to a key enabler of the region’s agricultural sustainability and profitability.

Unlocking Investment with Government-Backed Agricultural Credit

A compelling aspect of this business case is its alignment with Brazilian national policy. The government offers several credit lines designed to help farmers invest in technology to improve efficiency and sustainability. These programs can be leveraged to create strong, localized demand for the factory’s output.

Key programs include:

- Pronaf (Programa Nacional de Fortalecimento da Agricultura Familiar): Provides financing for small family farmers to invest in modernization, including renewable energy systems.

- Pronamp (Programa Nacional de Apoio ao Médio Produtor Rural): Offers similar credit lines for medium-sized agricultural producers.

- Moderinfra (Programa de Modernização da Frota de Tratores Agrícolas e Implementos Associados e Colheitadeiras): Supports investment in infrastructure, which can include energy generation systems vital for modern farming.

A local solar module factory makes it significantly easier for farmers and cooperatives to use these funds, as they can source reliable, locally produced solar technology with dedicated technical support.

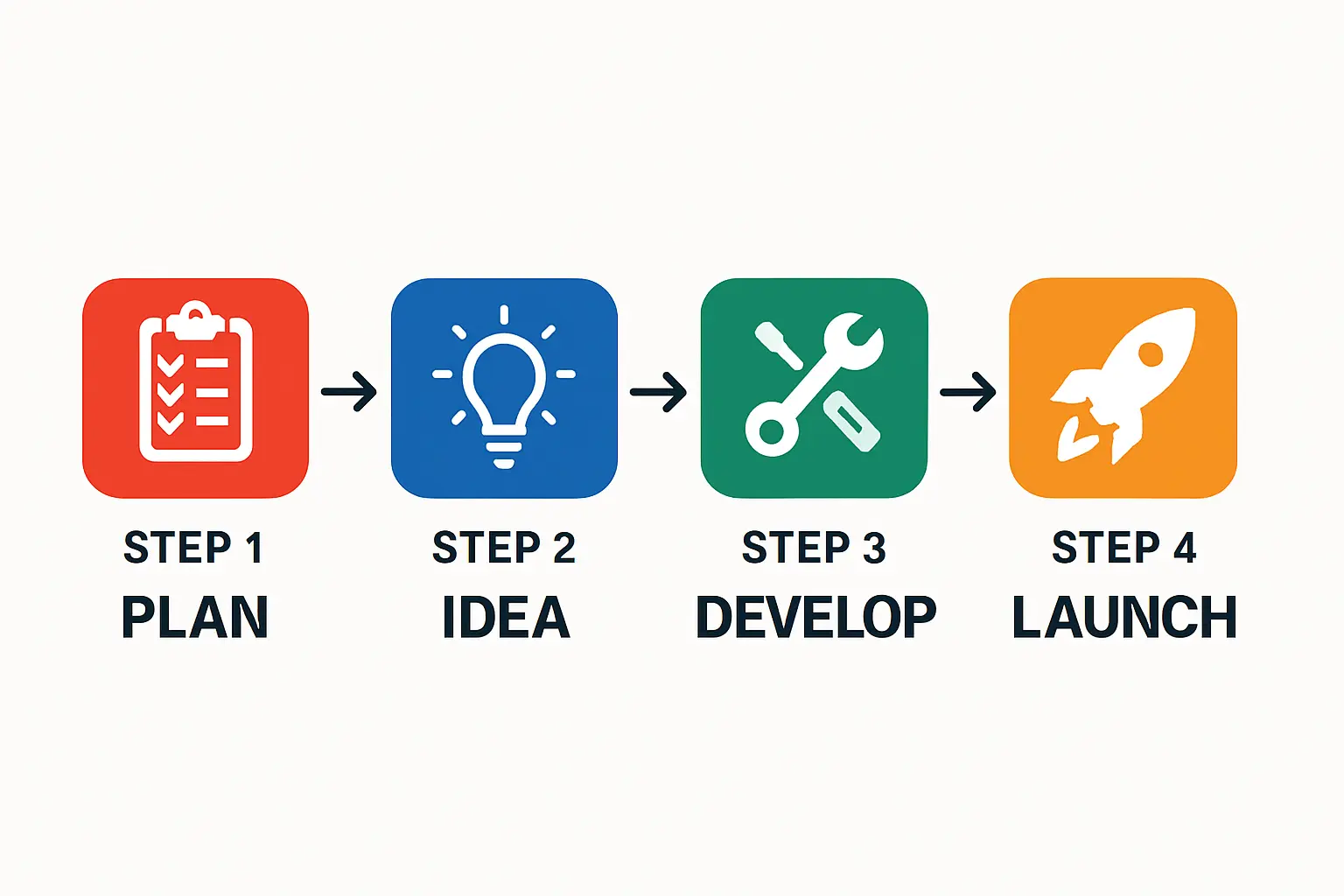

The EU-Based Photovoltaic Manufacturing Solution Partner Turnkey Blueprint: From Concept to Production

Entering the solar manufacturing industry doesn’t require a deep technical background. Setting up a turnkey solar panel production line is a structured process that handles all technical complexities for the investor.

Based on premier EU provider’s experience with turnkey projects, implementation follows a clear, four-phase approach designed to integrate the factory into the agricultural ecosystem.

Phase 1: Business and Financial Planning

The initial phase focuses on developing a robust business plan. This involves defining the factory’s production capacity (e.g., 50 MW per year), identifying target cooperatives, and structuring the financial model. A clear understanding of the investment requirements for a solar factory is crucial for securing funding, whether from private investors or financial institutions.

Phase 2: Factory Design and Equipment Selection

In this phase, the physical layout of the factory is designed for optimal workflow and safety. Selecting the right solar module manufacturing equipment is critical, as this choice depends on the specific types of modules best suited for the agricultural market.

Phase 3: Implementation and Training

This phase covers the shipment, installation, and commissioning of all machinery. A core component of the turnkey approach is comprehensive training for the local workforce. This knowledge transfer empowers the local team to operate and maintain the production line independently, ensuring long-term success.

Phase 4: Production and Market Support

Once the line is operational, the focus shifts to producing high-quality solar modules and supplying them to the target market. Ongoing technical support ensures production remains efficient and helps the factory adapt to future technological advancements.

Tailoring Technology for Agricultural Needs

Not all solar modules are created equal. A factory dedicated to the agribusiness sector can produce panels optimized for specific applications, creating a significant competitive advantage.

A primary agricultural need is reliable solar water pumping to support irrigation, a major cost center for many farms. Beyond this, an advanced application known as agrivoltaics offers a powerful dual use for land. In agrivoltaics systems, solar panels are installed in a way that allows crops to be cultivated underneath.

For this application, bifacial solar modules are particularly effective. These modules capture sunlight on both their front and back surfaces, generating power from direct sunlight above and from light reflected off the ground and crops below. This technology can increase energy yield by up to 25% compared to conventional panels, making it a highly efficient solution for land-conscious agricultural businesses.

Frequently Asked Questions (FAQ)

What is the typical investment size for such a factory?

For a 20–50 MW semi-automated production line, the investment typically ranges between €1.5 million and €4 million. This includes machinery, installation, training, and initial raw materials.

How long does it take to get a factory operational?

With a structured turnkey approach, a solar module factory can be fully operational in under 12 months from the start of the project.

Do I need a technical background in solar energy?

No. The turnkey model is designed for business professionals and investors who may not have a technical background. The engineering partner, like an EU PV factory turnkey supplier, manages all technical aspects, from planning and installation to staff training. The investor’s focus remains on business strategy and market development.

Why not just import cheaper solar panels?

Importing panels can involve complex logistics, import duties, and a lack of local technical support. A local factory builds trust, ensures a reliable supply, allows for module customization to local needs (e.g., specific frame strength for high winds), and contributes to the local economy—often a key factor for cooperatives and government bodies.

What kind of modules are best for agricultural use?

Robust, durable modules are essential for any farm application. For advanced uses like agrivoltaics, high-efficiency bifacial modules offer the best return on investment due to their ability to generate more power from a given area.

Conclusion and Next Steps

Establishing a local solar factory for Brazil’s agribusiness sector is a commercially sound investment that addresses a fundamental market need. The opportunity is supported by strong demand, favorable government financing, and a proven, structured implementation process.

By focusing on farmers’ needs and leveraging the powerful network of cooperatives, an investor can build a profitable enterprise that also contributes to the sustainability and energy independence of a vital economic sector.

For investors considering this path, the next step is to gain a deeper understanding of the implementation process. Learning more about the practicalities of starting a solar module factory provides the foundational knowledge needed to turn this concept into a reality. The pvknowhow.com platform offers structured educational materials and courses to guide investors through each stage of the journey.

Download the Brazil Agribusiness Solar Investment Blueprint (PDF)

Author: This case study was prepared by the

turnkey solar module production specialists at J.V.G. Technology GmbH

It is based on real data and consulting experience from J.v.G. projects

worldwide, including installations ranging from 20 MW to 500 MW capacity.