Disclaimer: This case study represents a composite example derived from real-world

consulting work by J.v.G. Technology GmbH in solar module production and factory optimization. All data points are realistic but simplified for clarity and educational purposes.

The $5 Million Blueprint: How to Launch a 50 MW Solar Factory in the UAE

When most entrepreneurs consider solar manufacturing, they often picture vast, billion-dollar gigafactories that dominate the market. This perception can be intimidating, suggesting the industry is accessible only to the largest global players.

For the discerning investor, however, a different and more strategic opportunity exists: the boutique production model. This model focuses on flexibility, specialized products, and regional market needs, offering a compelling business case—especially in a forward-thinking hub like the United Arab Emirates.

This blueprint details how to establish a 50 MW ’boutique’ solar module assembly facility in the UAE. It explores how a focused investment, aligned with national strategic goals, can create a viable and highly profitable enterprise by targeting niche, high-value market segments.

The Strategic Advantage of Manufacturing in the UAE

An industrial project’s success hinges on its operating environment. The UAE offers a uniquely favorable landscape for solar manufacturing, driven less by market chance and more by deliberate government policy.

Alignment with National Vision

The UAE’s commitment to a sustainable future is cemented in ambitious national strategies. The UAE Net Zero 2050 and Energy Strategy 2050 initiatives aim to dramatically increase the share of clean energy in the country’s grid, creating consistent, long-term domestic demand for solar components.

Furthermore, the Dubai Industrial Strategy 2030 specifically targets the growth of advanced manufacturing sectors. A modern solar module factory aligns perfectly with this vision, positioning it to receive potential government support and benefit from a pro-industrial ecosystem.

The In-Country Value (ICV) Program

Perhaps the most compelling commercial advantage is the UAE’s In-Country Value (ICV) Program. This procurement-led initiative gives preferential treatment to companies that contribute to the local economy.

For government and state-affiliated projects, tender bids from companies with a high ICV score—achieved through local manufacturing and sourcing—are heavily favored. This means a UAE-based module manufacturer has a distinct, government-mandated competitive edge over foreign importers, effectively creating a protected market for a significant portion of utility-scale and commercial projects.

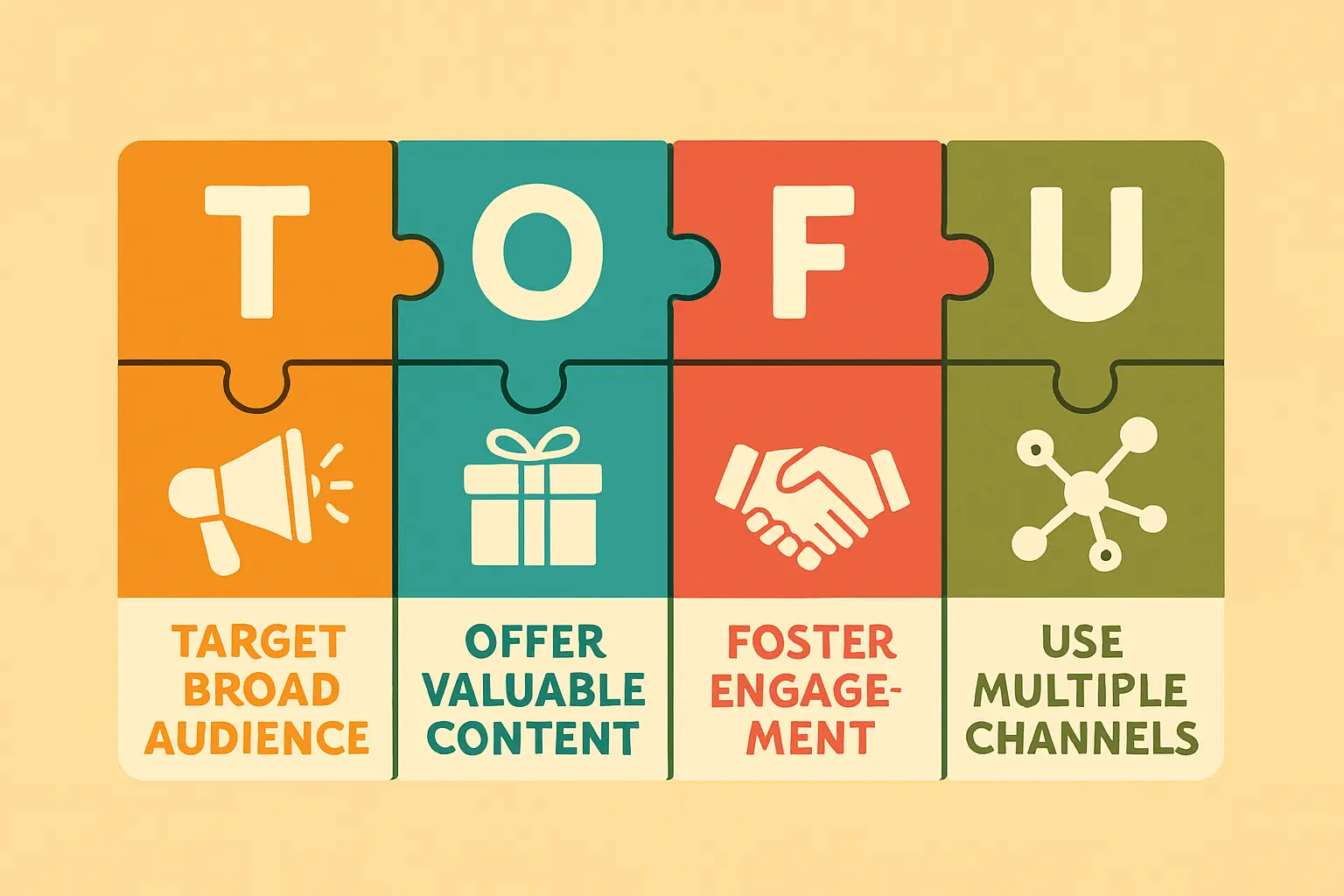

Defining the ‘Boutique’ Manufacturing Model

A 50 MW production line is not designed to compete with mass-market commodity producers on volume. Instead, its strength lies in agility and specialization.

Here’s what a ’boutique’ 50 MW facility looks like in practice:

-

Annual Output: Approximately 125,000 to 150,000 solar modules.

-

Capital Expenditure (CAPEX): An estimated investment of USD 3–5 million for machinery and setup, a fraction of the cost of a gigawatt-scale plant.

-

Flexibility: The ability to quickly adapt production to new technologies (e.g., TOPCon, HJT) or produce custom module formats for specialized applications like building-integrated photovoltaics (BIPV).

-

Focus: Targeting high-margin niches rather than competing on the price of standard residential modules.

This model allows an entrepreneur to enter the market with a manageable investment while serving premium segments that larger players often overlook.

The Product: Why Specialized DESERT+ Modules Are Key

The climate across the Middle East, North Africa, and surrounding regions presents unique challenges for standard solar modules. Extreme heat, abrasive sand, and high UV radiation can accelerate degradation and significantly reduce a power plant’s lifetime energy yield.

A boutique UAE factory is ideally positioned to produce DESERT+ modules—panels engineered specifically for these arid, high-temperature environments.

These modules typically feature:

-

High-Temperature Performance: Advanced cell technology that minimizes power loss as ambient temperatures rise.

-

Durable Materials: Robust frames, reinforced glass, and specialized encapsulants to withstand sand abrasion and prevent moisture ingress.

-

Advanced Coatings: Anti-reflective and anti-soiling coatings to maximize light absorption and reduce the impact of dust accumulation.

By manufacturing a product tailored to solve this pressing regional problem, the factory moves beyond price competition to compete on performance, reliability, and long-term value.

Operational Blueprint: Location, Line, and Labor

A clear operational plan is essential to any successful business case. The UAE’s infrastructure offers distinct advantages in every key area.

Strategic Location: The Free Zone Advantage

Establishing the factory within a free zone such as KEZAD (Khalifa Economic Zones Abu Dhabi) or JAFZA (Jebel Ali Free Zone) offers substantial benefits:

-

100% foreign ownership.

-

Exemption from corporate and personal income taxes.

-

Streamlined customs and import/export processes.

-

Access to world-class logistics infrastructure, including major seaports and airports.

This simplifies the corporate structure and optimizes the supply chain for both raw material imports and finished product exports.

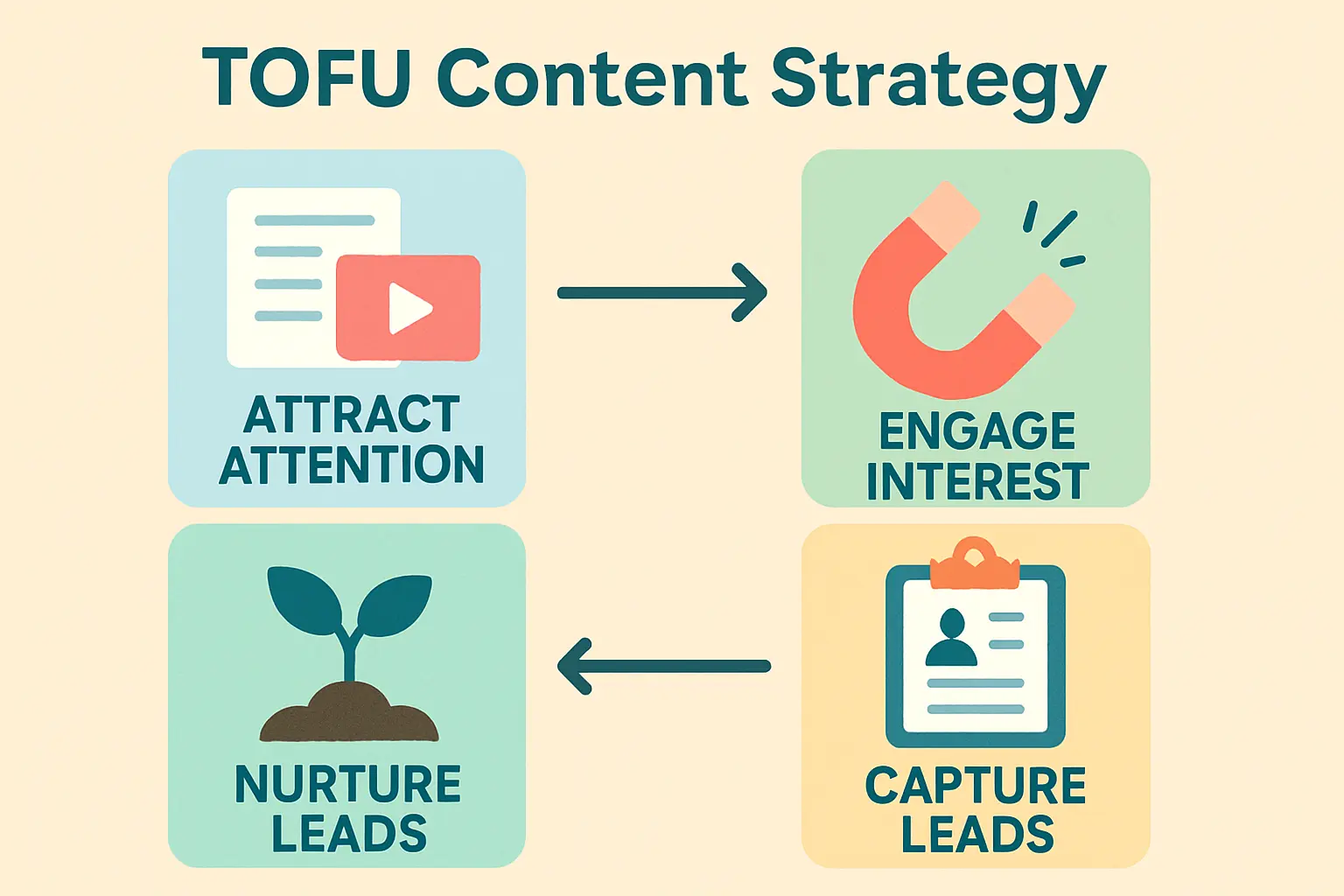

The Production Line and Facility

The assembly line is the heart of the operation. A semi-automated 50 MW solar module production line occupies a modest footprint, typically requiring a 2,500–3,000 square meter factory building. The process involves several key stages, from cell stringing and bussing to lamination and final testing.

Labor and Skill Requirements

A team of just 25 to 30 employees per shift can efficiently operate the 50 MW line, including technicians, operators, and quality control staff. While specialized engineering oversight is crucial, the operational team can be trained on-site, simplifying recruitment.

Financial Outline and Project Timeline

Investors need a clear understanding of the financial requirements and execution timeline.

Investment and Financing

The primary capital expenditure for machinery is in the USD 3–5 million range. Additional costs for the facility lease, initial raw materials, and working capital should also be factored into the overall business plan.

Fortunately, industrial projects aligned with the UAE’s strategic goals can often access favorable financing. Institutions like the National Development Bank (NDB) and the Abu Dhabi Fund for Development (ADFD) have mandates to support the nation’s industrial diversification and may be viable funding partners.

Project Execution Timeline

With a clear plan and an experienced technical partner, a 50 MW production line can become operational surprisingly quickly. A typical timeline, from the final investment decision to the first certified module coming off the line, is just 9 to 12 months.

Execution Partner: The Role of Technical Expertise

For an entrepreneur entering the solar industry from another sector, navigating the technical complexities of factory planning, machine procurement, and process optimization can be the greatest challenge. This makes a partnership with a specialized engineering firm invaluable.

The EU PV factory turnkey supplier’s project experience shows that engaging a partner for turnkey solar manufacturing solutions de-risks the entire process. Such a partner handles everything from initial line design and machine selection to installation, commissioning, and staff training. This frees the business owner to focus on commercial strategy, financing, and market development, confident that the technical execution is in expert hands.

Frequently Asked Questions (FAQ)

Why 50 MW and not a larger capacity?

The 50 MW ’boutique’ scale is a strategic choice. It keeps the initial investment manageable, allows for greater operational flexibility, and enables a focus on high-margin, specialized products. It avoids direct competition with global commodity giants, carving out a profitable niche instead.

Can this manufacturing model be replicated in other GCC countries?

Yes, the core principles of this model apply across the Gulf Cooperation Council (GCC) and the wider MENA region. Many countries are implementing similar local content programs and have a strong demand for climate-specific solar modules. The key is to adapt the strategy to the specific regulatory and market conditions of each country.

What are the main challenges to anticipate?

The primary challenges are typically securing a consistent supply chain for high-quality raw materials, training and retaining a skilled technical team, and establishing initial sales channels. A robust business plan and an experienced technical partner can help mitigate these challenges effectively.

Is prior experience in manufacturing required to start such a venture?

While manufacturing experience is beneficial, it is not a prerequisite. This business model often targets successful entrepreneurs from other industries who possess strong commercial acumen. By leveraging turnkey solutions and expert consultancy, they can bridge the technical knowledge gap and focus on their core strengths in business development. Platforms like pvknowhow.com also provide structured e-courses to assist with the initial planning phase.

Download the UAE Solar Module Investment & Launch Case Study (PDF)

Author: This case study was prepared by the

turnkey solar module production specialists at J.V.G. Technology GmbH

It is based on real data and consulting experience from J.v.G. projects

worldwide, including installations ranging from 20 MW to 500 MW capacity.