Disclaimer: This case study represents a composite example derived from real-world

consulting work by J.v.G. Technology GmbH in solar module production and factory optimization. All data points are realistic but simplified for clarity and educational purposes.

A Strategic Opportunity for a Private Family Office

For a forward-thinking family office in Qatar, diversifying assets beyond traditional sectors is no longer just an option—it is a strategic imperative. As the nation pivots towards its ambitious Vision 2030, which targets generating 20% of its energy from renewable sources, a unique industrial opportunity emerges.

This is not about speculative ventures. It is about building tangible, long-term assets that align with national priorities and capture value from the region’s most abundant resource: the sun.

This document outlines a detailed investment case for establishing a 100 MW solar module manufacturing facility in Qatar. It provides a blueprint for a private family office to enter the renewable energy sector, not merely as a passive investor, but as a key industrial player producing high-performance technology tailored for the demanding climate of the Gulf region.

The Strategic Rationale: Why Solar Manufacturing in Qatar?

The decision to invest in local solar manufacturing is rooted in strong economic and policy drivers. Qatar’s high gross domestic product per capita, combined with its strategic goals, creates an ideal environment for this venture.

Alignment with Qatar National Vision 2030

The Qatari government is actively seeking to diversify its economy away from hydrocarbon dependence. Projects that build local industrial capacity and contribute to the green energy transition are therefore highly favored. Establishing a solar module factory directly supports the twin pillars of economic diversification and environmental development outlined in Vision 2030, positioning the investment for potential government support and long-term stability.

Unmatched Natural Advantage

Qatar possesses one of the highest Global Horizontal Irradiance (GHI) levels in the world, averaging between 2,000 and 2,200 kWh/m² annually. This exceptional solar resource ensures strong and consistent performance for solar installations, driving sustained demand for high-quality modules. Local manufacturing enables the production of panels specifically engineered to maximize output in these high-irradiance conditions.

Growing Regional Demand and Policy Support

Qatar’s state-owned utility, KAHRAMAA, has set a target of installing 5 GW of solar power by 2035. This policy creates a predictable, large-scale domestic market. Projects like the 800 MWp Al Kharsaah Solar PV Power Plant signal the scale of this ambition.

Beyond Qatar, the entire GCC region is experiencing a surge in solar energy adoption, creating significant export opportunities for modules made in Qatar that benefit from regional trade agreements and logistical advantages.

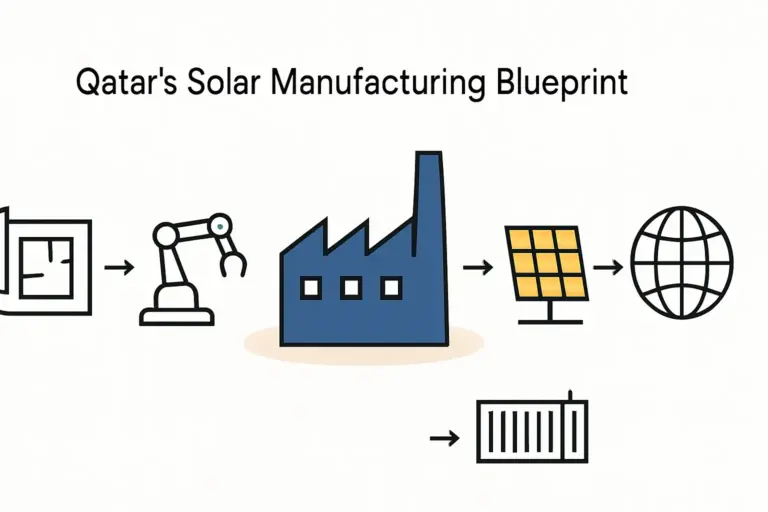

A Blueprint for a 100 MW Turnkey Solar Factory

A 100 MW factory is a significant industrial undertaking, capable of producing approximately 250,000 to 300,000 solar modules per year. For an investor without a technical background, the most efficient and de-risked pathway is a turnkey solution. This involves partnering with a technology and engineering expert who manages the entire process—from initial design to full-scale production.

Drawing on experience gained from European PV manufacturers’ turnkey projects, the setup involves several core components.

1. Site Selection and Infrastructure

The choice of location is critical. Industrial zones such as Mesaieed or Ras Laffan offer pre-existing infrastructure, streamlined logistics, and favorable utility connections. A 100 MW semi-automated production line typically requires a facility of approximately 5,000–7,000 square meters.

Crucially, this building must have advanced climate control systems to maintain the stable temperature and low humidity levels required for high-quality module lamination—a key consideration in Qatar’s environment.

2. Technology and Equipment: The DESERT+ Advantage

Standard solar modules often underperform in the extreme heat and dusty conditions of the Gulf. Focusing on specialized DESERT+ modules significantly strengthens the investment case. These modules are engineered with features such as:

-

High-Temperature Resistance: Utilizing materials and cell technologies that minimize power loss as temperatures rise.

-

Bifacial Technology: Capturing reflected sunlight from the ground, which is particularly effective over Qatar’s sandy terrain, increasing energy yield by up to 15%.

-

Durable Construction: Using robust frames and anti-reflective, self-cleaning glass to withstand sandstorms and reduce soiling losses.

The production line will be equipped with carefully selected solar panel manufacturing machines for cell stringing, lamination, framing, and testing, all calibrated to produce these specialized modules.

3. Human Capital and Training

A 100 MW factory is expected to create skilled employment for 50 to 70 individuals, including engineers, technicians, operators, and administrative staff. A critical component of a turnkey project is comprehensive training. The technical partner is responsible for training the local workforce to operate the machinery, manage quality control, and maintain the facility to international standards. Platforms like pvknowhow.com also provide structured e-courses to help build foundational knowledge for key management personnel.

The Investment Lifecycle: From Vision to Profitability

A structured, phased approach is essential for a project of this scale. The timeline from initial decision to first module production can realistically be completed within 12 to 15 months.

Phase 1: Feasibility and Business Planning (Months 1–3)

This initial phase covers detailed market analysis, financial modeling, and a raw material sourcing strategy. It culminates in a comprehensive, bankable solar panel manufacturing business plan that validates the project’s viability for stakeholders and financial institutions.

Phase 2: Financing and Partner Selection (Months 3–6)

With a solid business plan, the family office can secure financing. Options in Qatar include self-funding, leveraging support from the Qatar Development Bank (QDB), or partnering with local commercial banks. Simultaneously, a formal agreement is signed with the turnkey technology partner who will execute the project.

Phase 3: Implementation and Setup (Months 6–12)

Managed by the turnkey partner, this execution phase includes:

-

Finalizing the factory layout and design.

-

Procuring, shipping, and installing all manufacturing equipment.

-

Establishing the supply chain for raw materials (glass, solar cells, aluminum frames, etc.).

-

Recruiting and initiating the training of the core operational team.

Phase 4: Operations and Market Entry (Month 12 onwards)

The final phase covers commissioning the production line, achieving initial quality certifications (e.g., IEC 61215, IEC 61730), and ramping up production. The commercial team then secures offtake agreements with local EPCs, developers, and regional distributors.

Financial Projections and Key Metrics for a 100 MW Facility

While precise figures depend on final equipment choices and site conditions, a family office can model the investment based on industry benchmarks.

-

Initial Capital Expenditure (CAPEX): The total investment typically falls in the range of $15 million to $25 million USD. This covers machinery, building modifications, initial raw material stock, and project management fees.

-

Operational Expenditure (OPEX): Key ongoing costs include the Bill of Materials (BOM), which represents 70-80% of the cost per module, followed by labor, electricity, and maintenance.

-

Revenue Streams: Primary revenue will come from sales to utility-scale solar farms in Qatar, commercial and industrial rooftop projects, and exports to neighboring markets like Saudi Arabia, the UAE, and Oman.

-

Profitability and ROI: With a focus on high-quality DESERT+ modules that command a premium over standard imports, the factory can achieve healthy profit margins. The projected payback period is typically between four and six years, delivering a strong and stable return on investment thereafter.

Navigating Challenges and Ensuring Success

A successful project requires a realistic understanding of potential challenges.

-

Supply Chain Resilience: Establishing reliable, cost-effective supply chains for high-grade raw materials is paramount. An effective turnkey partner will leverage their global network to secure these channels.

-

Climate-Specific Challenges: The operational plan must include robust maintenance protocols to manage the impact of dust and heat on machinery and the final product.

-

Market Competition: The key to competing with large-scale international manufacturers is to differentiate on quality, local availability, customer service, and the superior performance of climate-specific modules.

Frequently Asked Questions

-

Do we need a technical background to start a solar factory?

No. The turnkey model is specifically designed for business professionals and investors without a background in photovoltaic engineering. The technology partner handles all the technical expertise, from plant design to staff training and operational oversight. -

What is the typical timeline to get a 100 MW factory operational?

A well-managed turnkey project can be operational within 12 to 15 months from the final investment decision. -

How difficult is it to secure raw materials in the GCC region?

While key materials like solar cells are typically imported from Asia, many other components, such as glass and aluminum frames, can be sourced regionally. A thorough supply chain strategy is a core part of the initial business plan. -

What kind of government support is available in Qatar for such projects?

Qatar encourages industrial development through bodies like the Qatar Development Bank, which may offer favorable financing. Operating within special economic zones can also provide tax incentives and streamlined regulatory processes. -

Can we export modules manufactured in Qatar to other countries?

Yes. Modules manufactured in Qatar can be exported globally. The GCC region presents the most immediate and lucrative export market due to proximity and growing demand.

The Path Forward

For a Qatari family office, establishing a 100 MW solar module factory is more than an investment; it is a nation-building enterprise. It creates skilled jobs, enhances technological sovereignty, and positions the family’s portfolio at the forefront of the global energy transition. It represents a durable legacy, turning the nation’s sunlight into a tangible, profitable, and sustainable industrial asset.

For principals ready to explore this opportunity, the logical next step is a detailed analysis of the investment required for a solar panel factory to begin the due diligence process.

Download the 100 MW Qatar Solar Factory Investment Case (PDF)

Author: This case study was prepared by the

turnkey solar module production specialists at J.V.G. Technology GmbH

It is based on real data and consulting experience from J.v.G. projects

worldwide, including installations ranging from 20 MW to 500 MW capacity.