Disclaimer: This case study represents a composite example derived from real-world

consulting work by J.v.G. Technology GmbH in solar module production and factory optimization. All data points are realistic but simplified for clarity and educational purposes.

The global energy transition is unlocking significant industrial opportunities, but few locations offer the unique convergence of factors found in Saudi Arabia.

For an investor considering a solar panel manufacturing venture, the Kingdom provides more than just a market—it offers a strategic platform for creating a globally competitive, export-focused enterprise. This combination of ambitious national strategy, low operational costs, and prime logistical access makes a compelling case for establishing a large-scale production facility.

This blueprint outlines the strategic considerations for developing a 500 MW solar module factory within a Saudi Special Economic Zone (SEZ). It is designed to serve the growing energy demands of the GCC and North African markets, detailing a path for leveraging the country’s inherent advantages to build a profitable and sustainable manufacturing operation.

The Strategic Rationale: Why Saudi Arabia?

A successful manufacturing venture is built on strong economic and logistical advantages. Saudi Arabia offers a powerful combination of government support, cost efficiencies, and market access that is difficult to replicate.

Leveraging Vision 2030 for Global Competitiveness

Saudi Arabia’s Vision 2030, a national transformation plan, heavily emphasizes economic diversification and renewable energy. By 2030, the government aims to generate 58.7 GW of its electricity from renewable sources, creating a substantial and predictable domestic market for locally manufactured solar modules.

Furthermore, Local Content Requirements (LCRs) associated with these projects offer a significant advantage to producers based within the Kingdom. This creates a favorable environment for new entrants to establish a foothold before scaling for export.

The Unmatched Advantage of Low Energy Costs

Solar module manufacturing is an energy-intensive process. Electricity tariffs for industrial consumers in Saudi Arabia are among the lowest in the world, often ranging from just $0.01 to $0.02 per kWh.

This provides a fundamental cost advantage over competitors in Europe or even China, where energy costs can be several times higher. In an industry where production margins are critical, this single factor can profoundly impact long-term profitability and competitiveness.

A Logistical Hub for MENA and Beyond

Strategically located at the crossroads of Asia, Europe, and Africa, Saudi Arabia offers unparalleled logistical access to key growth markets. Demand for solar in the MENA region is projected to expand from 17 GW to over 132 GW by 2030. A factory based in the Kingdom is perfectly positioned to meet this demand with shorter shipping times and lower transportation costs than Asian suppliers.

Modern and efficient ports like Jeddah Islamic Port and King Abdullah Port provide the world-class infrastructure needed to import raw materials and export finished modules to Egypt, Jordan, the UAE, and the broader North African market.

Designing a Competitive Product: The DESERT+ Module

Competing on price alone is a challenging strategy. A more sustainable approach is to develop a product specifically engineered for the target market’s environmental conditions. The MENA region’s climate—characterized by high ambient temperatures, intense UV radiation, and abrasive sand—demands a more robust solar module than standard designs.

The proposed core product is a specialized ‘DESERT+’ module, designed for maximum performance and longevity in harsh desert environments. Its key features would include:

- High-Temperature Performance: Utilizing cells with a superior temperature coefficient to minimize power loss in extreme heat.

- Durable Materials: Incorporating reinforced, anti-reflective coated glass to withstand sand abrasion and specialized encapsulants and backsheets that resist degradation from high UV exposure.

- Robust Frame Design: A stronger, corrosion-resistant frame to handle high wind loads and ensure structural integrity over a 30-year lifespan.

By producing a technologically superior module tailored for the region, the business can position itself as a premium provider. This approach can command higher prices and achieve greater bankability for large-scale solar projects, whose financiers often seek components with proven durability.

The Financial Framework: Capitalizing on Special Economic Zones

Establishing the 500 MW facility within one of Saudi Arabia’s new Special Economic Zones (SEZs) enhances the business case considerably. These zones are designed to attract foreign investment by offering a suite of powerful financial incentives.

These benefits typically include:

- 0% Corporate Income Tax: For a period of up to 20 years, dramatically increasing net profitability.

- 0% Customs Duties: On all imported raw materials, machinery, and production equipment.

- 100% Foreign Ownership: Providing the investor with full control over the enterprise.

- Favorable Regulatory Environment: Streamlined processes for permits, licensing, and labor.

These benefits significantly lower both initial capital expenditure and ongoing operational costs, directly improving the project’s return on investment. While the investment for a 500 MW facility is substantial, the financial advantages of an SEZ make the project considerably more attractive and resilient.

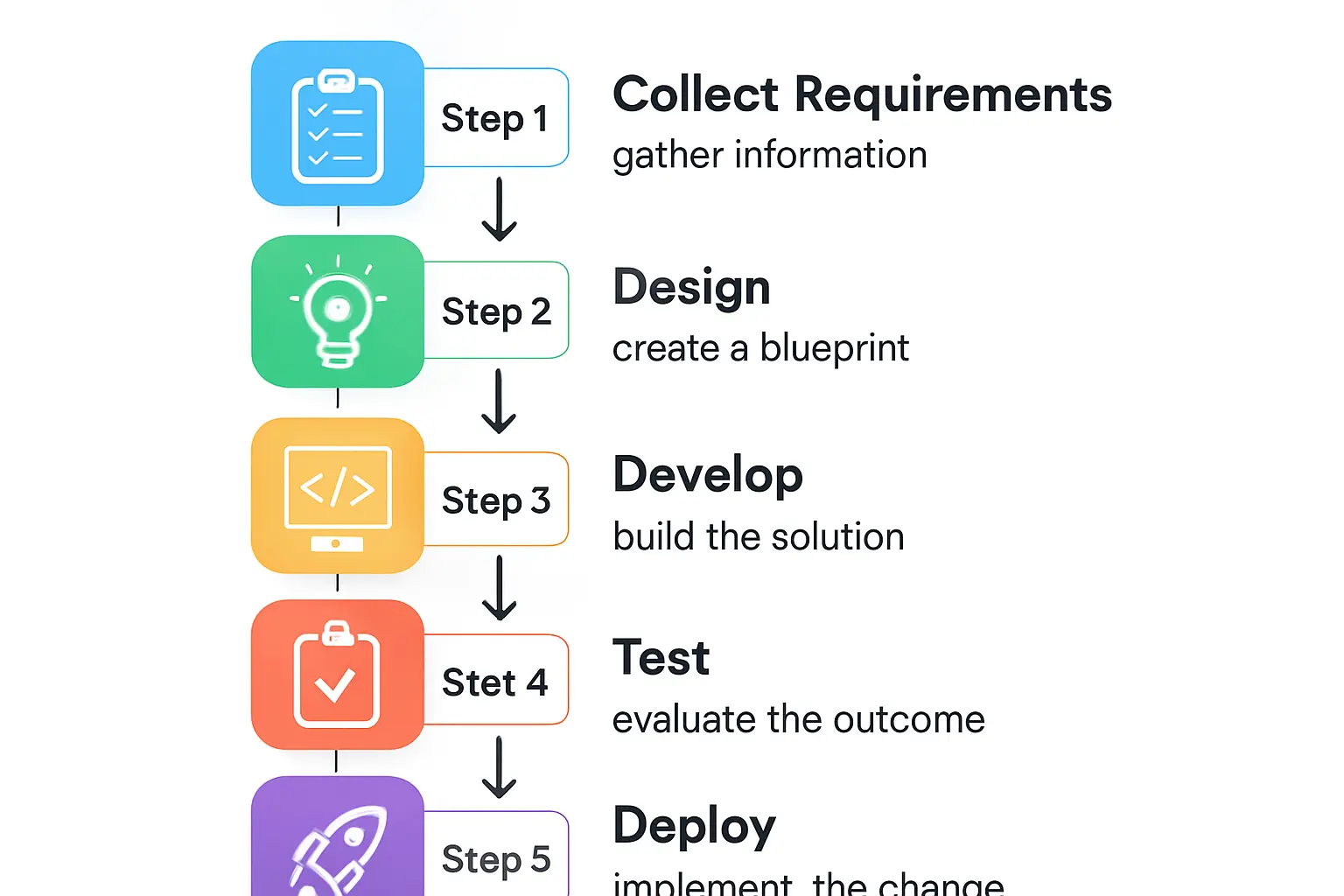

The Implementation Roadmap: From Blueprint to Production

Executing a project of this scale requires a structured, phased approach guided by experienced technical partners. A non-technical investor can navigate this complex process by collaborating with specialists to oversee the entire setup.

Based on a premier EU provider‘s experience with turnkey projects, the typical implementation path includes:

- Feasibility and Business Plan: Detailed financial modeling, site selection within an SEZ, and finalization of the product strategy.

- Engineering and Design: Custom layout of the factory floor, specification of all machinery, and design of utility infrastructure (power, water, compressed air).

- Procurement and Logistics: Sourcing all equipment for a complete turnkey solar manufacturing line, managing international shipping, and handling customs clearance.

- Installation and Commissioning: On-site installation of the production line by expert engineers, followed by rigorous testing and calibration to ensure it meets output and quality targets.

- Training and Ramp-Up: Comprehensive training for local operators and technicians on machine operation, quality control protocols, and maintenance procedures, leading to a gradual increase to full production capacity.

This structured process mitigates risks and ensures the facility is built to international standards, capable of producing certified modules for global export from day one.

Frequently Asked Questions (FAQ)

What is the typical timeline for a 500 MW factory?

From project kick-off to the start of production, a well-managed project of this scale can typically be completed in 12 to 15 months. This includes factory design, machine procurement, shipping, installation, and commissioning.

How many employees are needed for such a facility?

A semi-automated 500 MW production facility generally requires a workforce of approximately 250 to 300 personnel. This includes production line operators, maintenance technicians, quality control staff, engineers, and administrative personnel, spread across multiple shifts.

What are the key international certifications required for export?

To export to most international markets, modules must be certified to standards set by the International Electrotechnical Commission (IEC), such as IEC 61215 (design qualification) and IEC 61730 (safety qualification). Certifications from recognized bodies like TÜV are essential for market acceptance.

Can a non-technical investor succeed in this industry?

Absolutely. An entrepreneur’s success in this field depends not on being a photovoltaic expert, but on having a sound business strategy and partnering with a competent technical consultancy to manage the engineering, procurement, and implementation phases. pvknowhow.com provides structured resources to help business professionals navigate this journey.

Conclusion and Next Steps

Establishing a 500 MW export-oriented solar module factory in Saudi Arabia is a timely and strategic business opportunity. The combination of government support through Vision 2030, extremely low energy costs, a prime logistical location, and significant financial benefits from an SEZ lays a powerful foundation for success.

By focusing on a specialized, high-performance product engineered for the region, the facility can become a market leader supplying the rapidly growing energy markets of the Middle East and North Africa.

While the undertaking is significant, it is entirely manageable with a clear blueprint and the right technical partnership. For investors ready to explore the fundamentals, our guide on how to start a solar panel manufacturing business provides a comprehensive overview of the steps involved.

Download the 500 MW Solar Factory Export Strategy Case Study (PDF)

Author: This case study was prepared by the

turnkey solar module production specialists at J.V.G. Technology GmbH

It is based on real data and consulting experience from J.v.G. projects

worldwide, including installations ranging from 20 MW to 500 MW capacity.