Disclaimer: This case study represents a composite example derived from real-world

consulting work by J.v.G. Technology GmbH in solar module production and factory optimization. All data points are realistic but simplified for clarity and educational purposes.

In Oman’s dynamic energy sector, In-Country Value (ICV) is not just a policy—it is a fundamental part of every major tender and contract negotiation. Achieving a high ICV score is a critical differentiator that often determines the success of multi-million Omani Rial bids.

While many businesses focus on optimizing existing operations to meet these targets, a more strategic, forward-looking opportunity lies in local solar module manufacturing. This approach transforms the ICV requirement from a compliance obligation into a powerful engine for diversification and growth. By establishing a local solar module production line, a company can directly address core ICV pillars while creating a new, profitable venture that aligns perfectly with the goals of Oman Vision 2040.

Understanding the ICV Framework and Its Strategic Importance

Introduced to retain more of the oil and gas industry’s wealth within Oman, the ICV program is designed to localize supply chains, develop local talent, and stimulate economic diversification. Companies are certified and scored on their contributions across several key areas, including:

- Goods & Services: The value of goods manufactured and services provided within Oman.

- Investment in Fixed Assets: Capital expenditure on local facilities and infrastructure.

- Omanization: The development and employment of the Omani workforce.

- Local Supplier Development: Sourcing from Omani small and medium-sized enterprises (SMEs).

For established energy firms, continuously improving this score can be an ongoing challenge. Investing in a local solar factory, however, naturally addresses each of these pillars, providing a clear and quantifiable path to a higher ICV certification.

The Strategic Intersection: Oman Vision 2040 and Local Manufacturing

Oman’s national strategy is clear: a significant shift toward renewable energy is a top priority. The Sultanate aims for renewables to generate at least 30% of its electricity by 2030, a goal requiring the installation of thousands of megawatts of solar capacity. This national mandate creates a substantial, predictable domestic market for solar panels.

At present, this demand is met almost exclusively by imports. This reliance creates strategic vulnerabilities and a significant outflow of capital—the very issues the ICV program was designed to mitigate.

A local solar module factory stands at the intersection of these two national priorities. It leverages the guaranteed demand created by Vision 2040 to build a business that is inherently a high-performer in the ICV framework.

A Turnkey Solar Factory: The Blueprint for Maximizing ICV

A turnkey solar module production facility offers a structured, efficient pathway for new entrants into the manufacturing sector. For business professionals without deep technical expertise in photovoltaics, this model de-risks the investment by providing a complete, ready-to-operate solution. Such a venture directly boosts a company’s ICV score in several ways.

Investment in High-Value Assets and Local Goods

The primary investment in a factory—the building, machinery, and infrastructure—contributes directly to the ‘Fixed Assets’ component of the ICV score.

Furthermore, while certain specialized components like solar cells may initially be imported, many other materials can be sourced locally. Items such as aluminum frames, junction boxes, glass, and packaging materials can be procured from or developed with Omani suppliers, directly increasing the ‘Goods & Services’ contribution.

Omani Workforce Development and Knowledge Transfer

A semi-automated solar module factory with a 20-50 MW annual capacity typically requires a workforce of 25 to 40 employees. These are not just manual labor positions, but skilled roles for technicians, engineers, quality control specialists, and administrative staff. A turnkey project partner like an expert-led European solar project architecture and modeling firm typically includes comprehensive training programs, facilitating the transfer of technical knowledge and creating a highly skilled local workforce in line with the nation’s Omanization goals. [Link: Learn more about how to start a solar factory with our comprehensive guide.]

Fostering a Local Supplier Ecosystem

The impact extends beyond the factory walls. A local manufacturing plant becomes an anchor for a new industrial ecosystem, creating opportunities for Omani SMEs in logistics, raw material supply, equipment maintenance, and waste management. Crucially, it stimulates the growth of local solar installation companies, giving them a competitive advantage through access to locally manufactured, readily available modules. This ripple effect is a powerful contributor to a company’s overall ICV score.

The Business Case Beyond ICV: Building a Resilient, Profitable Venture

While the ICV benefits are compelling, a solar module factory is a robust business opportunity in its own right, offering a strategic path to diversify revenue away from the volatility of traditional energy markets.

Securing the National Solar Supply Chain

Local module manufacturing reduces Oman’s dependency on international markets, which are often subject to logistical disruptions, price fluctuations, and geopolitical risks. A domestic factory bolsters supply chain security for the nation’s critical energy transition projects, creating a significant value proposition for both government and private-sector utility-scale solar developments.

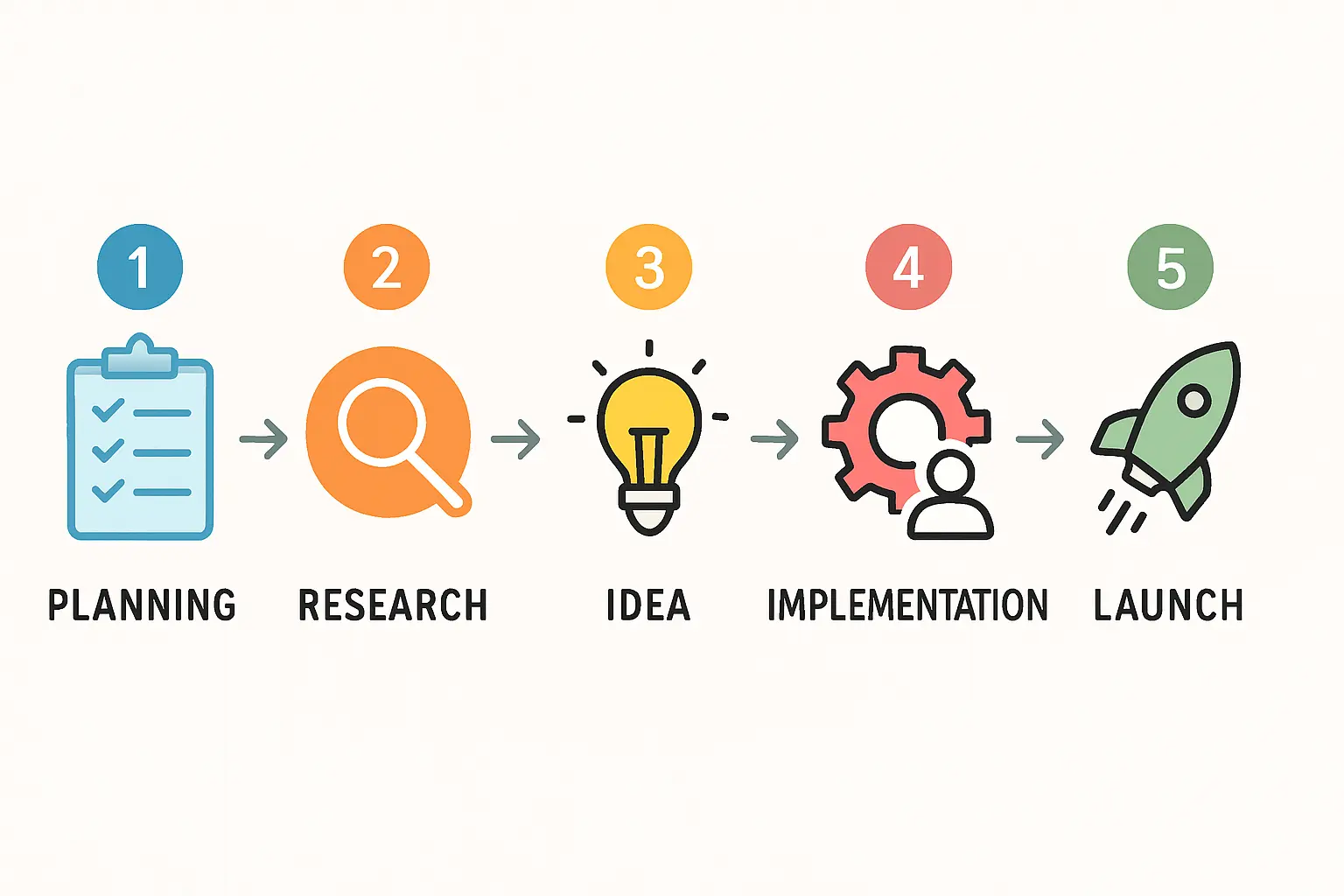

A Phased and Scalable Investment Model

Entering the solar manufacturing industry does not require a giga-factory from day one. A strategic entry with a 20 to 50 MW line allows an investor to establish a market presence, build a brand, and develop technical expertise with a manageable capital outlay. Based on experience gained from European PV manufacturers’ turnkey projects, such a facility can be planned, built, and commissioned in under 12 months. [Link: This guide outlines typical investment requirements for a 20–50 MW setup.] As demand grows, the production line can be expanded modularly.

Frequently Asked Questions (FAQ)

What is the typical initial investment for a turnkey solar factory?

A semi-automated production line with an annual capacity of 20-50 MW generally requires an investment in machinery between €1.5 million and €3 million. This excludes the cost of the building and working capital.

Does the business owner need to be a solar technology expert?

No. The turnkey model is specifically designed for entrepreneurs and investors who are not photovoltaic experts. The technical partner provides the process knowledge, machine integration, and staff training required to run the operation successfully. The owner’s expertise in business management, finance, and local market dynamics is what drives success.

How long does it take for a new factory to become operational?

With a clear plan and an experienced technical partner, a new solar module production line can typically be operational within 10 to 12 months from the project start date.

Can a local Omani factory compete with large international manufacturers?

Yes, particularly in domestic and regional markets. A local manufacturer’s advantages extend beyond price per watt. Key differentiators include faster delivery times, no import duties (within the GCC), product specifications customized for local climate conditions (like high heat and dust), and the significant commercial advantage of contributing to a client’s ICV score.

Conclusion: Aligning Corporate Growth with National Vision

For energy companies in Oman, investing in a turnkey solar module factory is a strategic decision. It directly addresses the challenge of maximizing In-Country Value, creating a powerful competitive advantage in major contract tenders.

Beyond compliance, this represents a commercially sound diversification into a high-growth sector central to Oman Vision 2040. By establishing local production, a business can create a profitable new revenue stream, strengthen national supply chain resilience, and play a pivotal role in Oman’s sustainable energy future. This is a business model where corporate success and national interest are perfectly aligned.

Download the Oman Solar In-Country Value (ICV) Case Study (PDF)

Author: This case study was prepared by the

turnkey solar module production specialists at J.V.G. Technology GmbH

It is based on real data and consulting experience from J.v.G. projects

worldwide, including installations ranging from 20 MW to 500 MW capacity.