Disclaimer: This case study represents a composite example derived from real-world

consulting work by J.v.G. Technology GmbH in solar module production and factory optimization. All data points are realistic but simplified for clarity and educational purposes.

Qatar’s commitment to renewable energy, underscored by its National Vision 2030 and landmark projects like the 800 MW Al Kharsaah solar power plant, creates a significant opportunity for industrial diversification.

As the nation aims to generate at least 2 GW of solar power by 2030, a domestic market for high-quality, locally manufactured solar modules is emerging. For an entrepreneur or business leader looking to enter this sector, building a large-scale manufacturing facility can seem daunting. Such an undertaking requires immense capital and specialized expertise from day one.

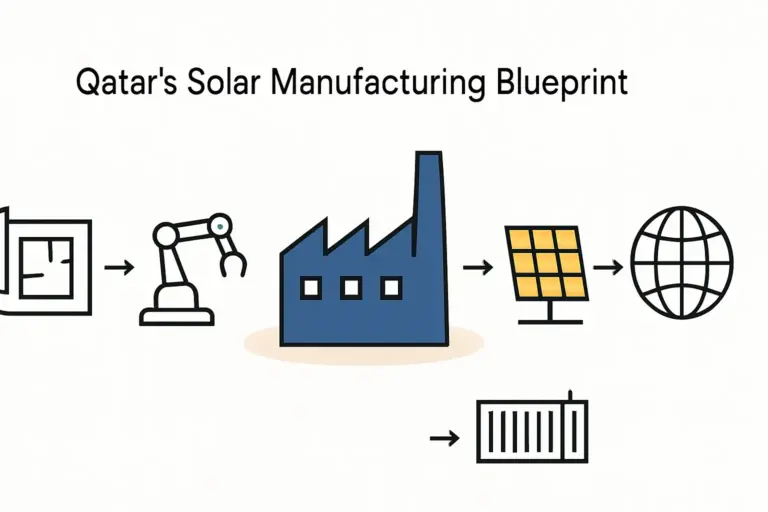

Yet the most successful market entries are often not the largest, but the most strategic. A phased approach—beginning with a pilot production line before scaling to a gigawatt-level facility—is a prudent, risk-mitigated path to establishing a major presence in Qatar’s solar industry. This method allows a new enterprise to build technical expertise, secure critical certifications, and establish market credibility before committing to a nine-figure investment.

The Unique Challenges and Opportunities of the Qatari Solar Market

Success in Qatar requires modules specifically engineered for the local environment. Standard solar panels, designed for moderate European climates, often underperform in the Gulf region. The primary environmental stressors include:

-

High Ambient Temperatures: Extreme heat significantly reduces power output and accelerates the degradation of solar cells.

-

Soiling: Frequent dust and sand accumulation on the module surface can block sunlight, reducing energy generation by 10–20% if not managed properly.

-

High Humidity: Combined with temperature fluctuations, humidity can lead to moisture ingress and corrosion, shortening a module’s lifespan.

Meeting these challenges requires specialized technology. DESERT+ modules, for example, use materials and construction techniques that optimize performance and durability in these conditions. A local manufacturer capable of producing these high-performance modules would hold a distinct competitive advantage, catering directly to the needs of large-scale solar projects in the region.

The Risks of a Large-Scale Initial Investment

Jumping directly into a 500 MW or larger facility presents several substantial risks for a new entrant, particularly one without a background in photovoltaics.

1. High Capital Expenditure and Unproven Operations

A fully automated 500 MW production line requires a significant upfront investment, often exceeding USD 50 million. Committing such capital without an experienced operational team or established production workflows is a high-stakes gamble. Any unforeseen technical challenges or process inefficiencies become incredibly costly at this scale.

2. Complex and Lengthy Certification Process

Before any solar modules can be sold for bankable projects, they must pass rigorous testing to achieve international certifications, primarily IEC 61215 (performance) and IEC 61730 (safety). Certifying a new product from a brand-new, large-scale factory is a complex undertaking. A single failure in the testing process can halt production, leading to significant financial losses and delays.

3. Building Market Trust from Zero

Securing offtake agreements and winning tenders for major solar projects requires a proven track record. Investors and project developers are understandably hesitant to purchase millions of dollars worth of modules from a newly established factory with no history of performance or reliability.

Planning a market entry starts with a comprehensive solar panel manufacturing business plan to map out these financial and operational hurdles.

Phase 1: The Pilot Line – A Foundation for Strategic Growth

The most effective way to mitigate these risks is to start with a smaller, semi-automated pilot line, typically with a capacity of 20–50 MW per year. This initial phase is not about maximizing output; it is about building a solid foundation for the future.

Objective 1: Master the Manufacturing Process

A pilot line serves as a real-world training ground. It allows the core team to understand the nuances of production, from handling raw materials to operating key machinery and implementing quality control checkpoints. This hands-on learning, a key takeaway from EU PV factory turnkey supplier projects, is invaluable. It creates a culture of technical competence within the organization before the pressures of mass production begin and is a critical element of a successful launch.

Objective 2: Secure Certifications Efficiently

Producing a small batch of modules for IEC certification from a pilot line is significantly faster and more cost-effective. The process is more controlled, allowing for precise adjustments to meet testing standards. Once certification is achieved, the module design is validated, and this ‘recipe’ can be confidently replicated when scaling up production.

Objective 3: Build Commercial Traction

With a certified, locally produced DESERT+ module, the company can approach potential customers with tangible proof of quality. These first modules can be used for demonstration projects, supplied to smaller-scale rooftop installations, or offered to project developers for field testing. This establishes a market presence, builds a brand reputation, and helps secure the initial offtake agreements necessary to finance a larger expansion.

Phase 2: Scaling to a 500 MW Automated Facility

Once certifications are secured, an experienced team is in place, and initial market traction is achieved, the enterprise is in a strong position to move to Phase 2: developing a large-scale, automated production facility.

The knowledge gained from the pilot line directly informs the design and equipment selection for the main factory. The pilot line can then be repurposed for research and development, testing new materials, or producing small batches of specialized, high-margin modules.

The transition to a large-scale operation becomes a calculated expansion rather than a speculative venture. The full-scale facility will then require a comprehensive list of manufacturing machinery, optimized for efficiency and throughput. By this stage, the company has de-risked the investment by proving its technical capabilities and confirming market demand for its product. This makes the venture far more attractive to financiers and large-scale customers, paving the way for it to become a key supplier for Qatar’s ambitious solar energy projects.

Frequently Asked Questions about Starting Solar Manufacturing in Qatar

What is the typical investment for a pilot line?

A semi-automated pilot line with a capacity of 20–50 MW typically requires an investment in the range of USD 2–5 million for machinery and setup. This is a fraction of the cost of a large-scale automated line, making it a more accessible entry point.

How long does it take to get a pilot line operational and certified?

With expert guidance, a pilot production line can be set up and commissioned within 8–12 months. The subsequent IEC certification process typically takes an additional 4–6 months, meaning a fully certified product can be ready for the market in under 18 months.

Why is DESERT+ technology specifically recommended for Qatar?

DESERT+ modules are engineered to counter the effects of high temperatures and soiling. They often feature higher temperature coefficients, anti-reflective and anti-soiling coatings on the glass, and robust sealing to prevent moisture ingress. The result is higher energy yields and a longer operational lifespan in Qatar’s climate compared to standard modules.

Can a non-technical entrepreneur succeed in this industry?

Yes, provided they partner with the right technical experts. An entrepreneur doesn’t need to be a solar engineer to build a successful manufacturing business—a key message of platforms like pvknowhow.com. The phased approach, combined with guidance from experienced consultants like established European turnkey engineering team, offers a structured path for business leaders to enter the industry with confidence.

Your Strategic Entry into Qatar’s Solar Future

Entering Qatar’s growing solar manufacturing market does not require a massive, high-risk leap. A strategic, phased approach—starting with a pilot line to build expertise and prove the product, followed by a well-planned expansion—offers a clear and prudent roadmap to success. This method transforms a daunting industrial project into a series of manageable, value-creating steps, positioning the enterprise to become a cornerstone of Qatar’s sustainable energy future.

Download the Qatar Solar Manufacturing Case Study (PDF)

Author: This case study was prepared by the

turnkey solar module production specialists at J.V.G. Technology GmbH

It is based on real data and consulting experience from J.v.G. projects

worldwide, including installations ranging from 20 MW to 500 MW capacity.