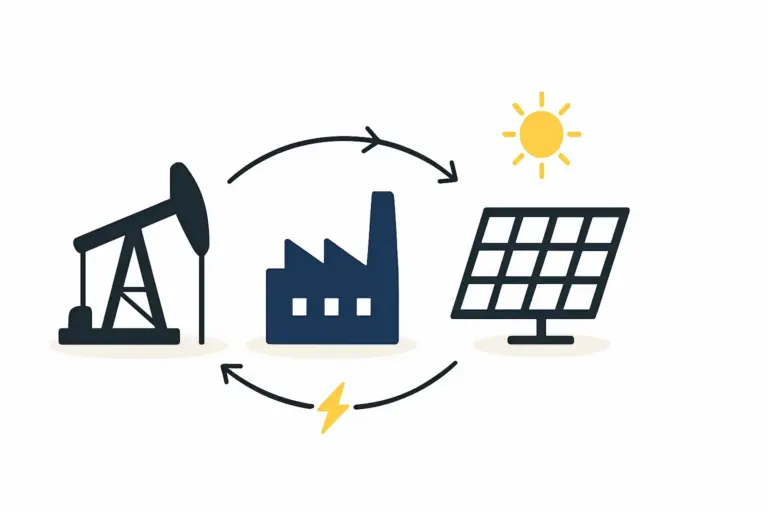

For generations, the wealth of many prominent Libyan families has been intrinsically linked to the nation’s vast oil reserves. This resource has fueled growth and opportunity, but its inherent price volatility and finite nature pose a long-term challenge to legacy planning.

A prudent family office today does more than manage existing assets; it actively seeks to build new, sustainable pillars of wealth for the future.

This guide outlines a compelling opportunity to do just that: establishing a 50-100 MW solar module manufacturing plant in Libya. This is more than an investment in a factory; it is an investment in industrial capacity, energy independence, and a tangible national asset that can serve Libya and the wider region for decades to come.

The Confluence of Opportunity: Why Solar Manufacturing in Libya?

Libya possesses a unique combination of natural and economic factors that make it an ideal location for solar module production. While the initial thought for many is simply to build solar farms, the greater strategic advantage lies in controlling the manufacturing of the core technology itself.

Unmatched Natural Resources

Libya is one of the most sun-rich countries in the world, receiving between 3,000 and 3,500 hours of sunshine annually. This immense solar irradiation is the primary raw material for a thriving solar energy sector, guaranteeing strong and consistent domestic demand for locally produced modules.

Pressing National Energy Demand

A growing population and the ongoing need for reconstruction place significant strain on the national grid. Local production of solar modules offers a direct solution for improving energy security, reducing reliance on imported fuels for power generation, and supporting the electrification of remote communities. This aligns with national priorities outlined in initiatives such as the ‘Renewable Energy Strategic Plan 2025.’

Economic Diversification as a National Imperative

The Libyan economy is heavily dependent on oil, which accounts for over 95% of export revenues. Establishing a high-tech manufacturing sector such as solar panel production is a direct and effective path to diversification. This creates a new revenue stream and fosters technical expertise, building a more resilient economic foundation.

Strategic Geographic Position

Located at the nexus of Africa, the Middle East, and Europe, Libya is perfectly positioned to become a regional hub for solar technology. Libyan-made solar modules can be highly competitive in neighboring African markets and even exported to Europe, leveraging the country’s proximity to reduce logistics costs.

The Turnkey Plant: A Managed Pathway into a New Industry

Entering a new, technically complex industry such as solar manufacturing can appear daunting for investors without a background in photovoltaics. This is where the turnkey model offers a clear, structured, and risk-mitigated path forward.

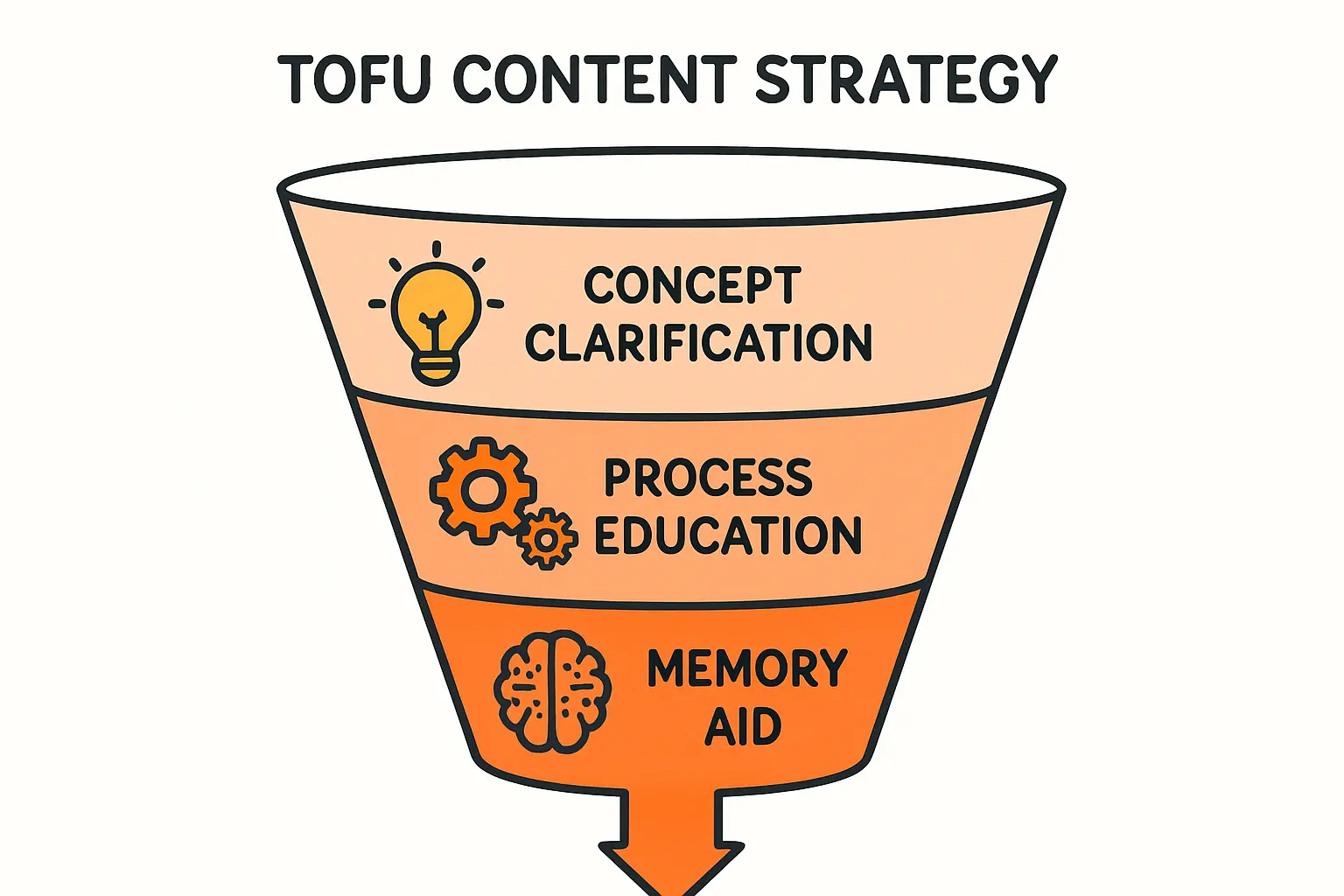

A turnkey solar module plant is a comprehensive project where an experienced engineering partner manages the entire process—from initial feasibility studies to the final commissioning of the factory—delivering a fully operational facility ready to begin production.

This process typically includes:

- Feasibility and Business Planning: Detailed analysis of market demand, financial projections, and site selection.

- Factory Design and Layout: Custom engineering of the facility to optimize workflow and efficiency.

- Equipment Procurement: Sourcing, testing, and shipping of all machinery for the solar module production line.

- Installation and Commissioning: On-site assembly and calibration of the production line.

- Staff Training and Know-How Transfer: Comprehensive training for local engineers, technicians, and operators to ensure self-sufficient operation.

- Certification and Quality Control: Guidance through international certification processes (e.g., IEC, TÜV) to guarantee a world-class product.

Based on experience from J.v.G. Technology GmbH turnkey projects, a facility of this nature can be planned, built, and commissioned in under 18 months, enabling a swift transition from investment decision to revenue generation.

Financial Profile and Strategic Returns

An investment in a solar module factory is a long-term industrial asset, fundamentally different from speculative financial instruments. It offers stability and tangible value creation.

Investment and Operational Metrics

For a 50-100 MW annual capacity plant, the typical investment requirements are as follows:

- Capital Investment: Approximately €10–20 million.

- Facility Size: 10,000–20,000 square meters of land for the factory and warehousing.

- Workforce: Creation of 50–100 direct jobs for skilled and semi-skilled local personnel.

- Timeline to Operation: 12–18 months.

The returns are generated not only from the sale of solar modules to domestic utility-scale projects, commercial installations, and residential users but also from the potential for export.

Investing in solar manufacturing provides a hedge against the volatility of commodity markets. It transforms a portion of hydrocarbon wealth into a productive asset in a sector defined by stable, long-term growth.

Building a Legacy Beyond Financials

The strategic value of this investment extends far beyond the balance sheet. For a family office focused on its legacy, a solar module factory represents:

- A Nation-Building Project: Directly contributing to the country’s infrastructure and energy independence.

- A Catalyst for Employment: Creating high-quality technical jobs for a new generation of Libyans.

- A Symbol of Innovation: Positioning the family and the nation at the forefront of a future-oriented industry.

Managing this complex undertaking requires a partner with deep engineering expertise and a proven track record. Specialist firms such as J.v.G. Technology GmbH provide the end-to-end project management needed to build the facility to international standards, on time, and within budget.

Frequently Asked Questions

- Why manufacture modules instead of just building solar farms?

Building solar farms is a valid investment, but it makes you a consumer of technology. Manufacturing modules makes you a producer and owner of that technology. It captures a higher-value part of the supply chain, creates more skilled jobs, and establishes a national industrial base that can supply countless solar farms for years to come.

- Is the local workforce skilled enough to operate such a factory?

A core component of any turnkey project is intensive knowledge transfer. The engineering partner is responsible for training local managers, engineers, and line operators to run the factory independently. These are skills readily acquired by individuals with a technical aptitude.

- What are the primary risks, and how are they mitigated?

The primary risks involve project execution, technology selection, and market access. These are best mitigated by partnering with an experienced turnkey provider. Such a partner helps develop a sound business plan, selects reliable and proven machinery, and ensures the final product meets the international quality standards required for bankable projects.

- How does a Libyan-made module compete with international imports?

A locally produced module has significant advantages. It avoids import tariffs and currency exchange risks while dramatically reducing shipping costs and delivery times for local projects. Furthermore, ‘Made in Libya’ can be a powerful factor for government and private sector projects focused on local content development.

The Next Step: From Vision to Viable Project

Diversifying a family’s legacy from oil wealth into sustainable industrial assets is a strategic decision that will shape its future for generations. Establishing a solar module factory in Libya is a robust, patriotic, and forward-thinking investment. It aligns with global trends, addresses urgent national needs, and builds a foundation for long-term prosperity.

For family offices ready to transform this vision into a viable project, the next step is to seek expert guidance. Explore the detailed feasibility studies and turnkey solutions that can make this patriotic and profitable investment a reality.