For many international observers, Libya presents a paradox: a nation with some of the highest solar irradiation potential in Africa, yet one where development is hobbled by persistent energy instability.

The national grid, heavily concentrated along the Mediterranean coast, often experiences daily blackouts lasting from six to twelve hours. For remote communities in the vast southern regions, this challenge is even greater, leaving critical infrastructure like clinics, schools, and water pumps without reliable power.

While importing solar modules may seem like a straightforward solution, a more strategic and sustainable approach lies in establishing local, decentralized solar manufacturing facilities. This model not only addresses the immediate need for power but also fosters long-term economic resilience and technical independence.

The Energy Paradox in Southern Libya

Libya’s geography gives it an exceptional solar resource, receiving an average of 2,000–2,200 kilowatt-hours per square meter annually. However, this natural wealth remains largely untapped. The centralized power infrastructure is fragile and fails to adequately serve the interior, particularly the vast Fezzan region encompassing cities like Sabha and Murzuq, and the remote southeastern oasis of Kufra.

This energy deficit creates significant obstacles to economic development and public service delivery. At the same time, transporting finished solar modules from northern ports across challenging terrain is a logistically complex and expensive undertaking that risks damaging the product. By producing power at the point of need, a decentralized strategy bypasses these challenges.

A Decentralized Solution: Local Production for Local Needs

Instead of relying on a fragile, long-distance supply chain, a decentralized plan involves setting up smaller, regional solar module factories. This approach marks a shift from energy importation to local energy creation.

The core benefits of this model include:

- Reduced Logistical Costs and Risks: Manufacturing modules locally eliminates the substantial costs and breakage risks associated with transporting fragile glass panels over long distances.

- Economic Empowerment: A local factory creates direct and indirect employment, contributing to regional economic stability and providing valuable technical skills.

- Energy Security and Independence: Communities gain control over their energy supply, reducing dependence on the unreliable national grid and volatile fuel imports for generators.

- Customized Technology: Production can be tailored to the demanding environmental conditions of the Sahara, ensuring module longevity and performance.

The Modular Factory Model

Beginning this transformation doesn’t require a massive, sprawling industrial complex. Modern manufacturing makes it possible to deploy a complete, modular turnkey solar manufacturing line within a compact and efficient facility. These setups are engineered for rapid implementation and can be scaled according to regional demand.

A typical small-scale factory with an annual capacity of 20–50 MW can be designed to fit within a modest industrial building. Experience with J.v.G. turnkey projects shows that a workforce of fewer than 30 trained individuals per shift is often all that’s needed to run such an operation.

This modular approach allows an investor or public entity to start with a manageable initial investment and expand production as the local market for solar installations grows.

Key Components of a Successful Regional Initiative

Launching a successful decentralized manufacturing project requires a holistic approach that integrates financing, workforce development, and appropriate technology.

Securing Investment and International Support

The strategic importance of stabilizing remote regions through energy access is well-recognized by international development bodies. Organizations like the United Nations Development Programme (UNDP) and the World Bank often support renewable energy projects in post-conflict or underserved areas, viewing them as critical catalysts for peace and prosperity.

A well-structured business plan can attract this type of co-financing, blending private investment with development aid. Entrepreneurs pursuing this path should prepare a detailed analysis of the solar factory investment requirements, including equipment, infrastructure, and operational costs.

Building a Skilled Local Workforce

Technology is only one part of the equation; human capital is the other. Training a local workforce is a core pillar of the decentralized model. This process not only ensures the efficient operation of the factory but also creates a new generation of technical experts within the community.

Modern solar manufacturing equipment is highly automated, but it still requires skilled operators for machine supervision, quality control, and maintenance. A structured training program, often provided by the equipment supplier, can effectively equip motivated local workers to become proficient technicians.

Technology Engineered for the Environment

The Libyan desert is one of the most demanding environments on Earth for any technology. Extreme daily temperature fluctuations, high UV radiation, and abrasive sandstorms can cause conventional solar modules to degrade prematurely.

Selecting the right photovoltaic technology is not just a preference—it is a requirement for long-term project viability. The manufacturing process in a local factory can be configured to produce modules specifically designed for these conditions. For example, J.v.G. Technology’s DESERT+ solar modules incorporate specialized materials and construction techniques to withstand high temperatures and abrasive sand, ensuring a service life of 25 years or more even in harsh climates. A local Libyan factory could be equipped to produce precisely this type of robust technology.

From Concept to Community Impact: A Phased Approach

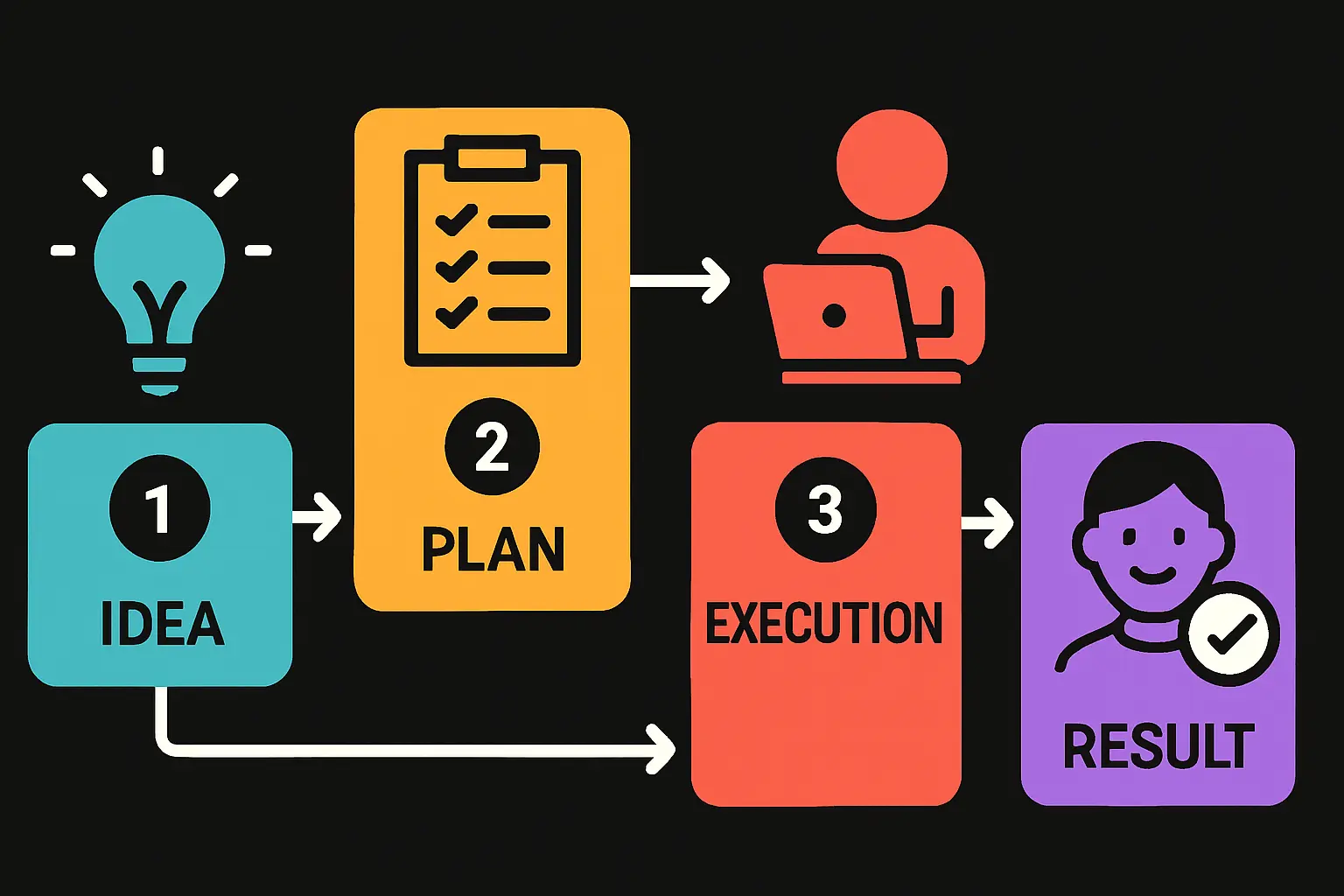

Bringing a decentralized solar factory online follows a logical and manageable sequence of steps:

-

Phase 1: Feasibility and Financing (3-6 Months): Develop a comprehensive business plan, conduct site selection studies, and secure the necessary investment from private and/or international partners.

-

Phase 2: Factory Setup and Commissioning (6-9 Months): Prepare the factory building, procure and install the manufacturing line, and commission the equipment.

-

Phase 3: Workforce Training and Initial Production (2-3 Months): Conduct intensive on-site training for the local team and begin initial production runs, focusing on quality control and process optimization.

-

Phase 4: Full-Scale Operation and Impact: With the factory running, the locally made modules can be deployed to power critical infrastructure—hospitals, schools, water wells, and local businesses—creating a virtuous cycle of energy independence and economic growth.

With the right process and expert guidance, a new solar module line can be fully operational in under a year.

Frequently Asked Questions (FAQ)

What is the typical size of such a factory?

A starter factory for regional supply typically has an annual production capacity of 20 to 50 megawatts (MW). This is sufficient to power thousands of homes and community facilities each year. The physical footprint for the production line itself can be as small as 1,500 square meters.

How many jobs can a small-scale factory create?

A 20–50 MW factory generally creates 25–35 direct jobs per shift in production, quality assurance, and maintenance. It also supports numerous indirect jobs in logistics, installation, and sales.

What kind of training is required for the workforce?

The workforce does not need prior experience in solar manufacturing. A comprehensive training program, typically lasting several weeks, covers machine operation, safety protocols, and quality control standards. The primary requirements are technical aptitude and a willingness to learn.

Is it difficult to source raw materials in a remote location?

While some raw materials like solar cells and specialized glass are sourced internationally, a well-planned logistics strategy ensures a steady supply. A key advantage of local manufacturing is that the most voluminous and fragile component—the glass—undergoes its final, risky journey as a raw material rather than a finished, high-value product.

Conclusion: A Pathway to a Brighter Future

The challenge of powering Southern Libya is not insurmountable; it is an opportunity to implement a forward-thinking, resilient, and empowering energy strategy. By establishing decentralized solar manufacturing facilities, the region can transform its greatest natural resource—the sun—into a foundation for lasting stability and prosperity. This model provides a clear, actionable blueprint for investors, entrepreneurs, and policymakers to build a self-sufficient energy future, one community at a time.