Disclaimer: This case study represents a composite example derived from real-world

consulting work by J.v.G. Technology GmbH in solar module production and factory optimization. All data points are realistic but simplified for clarity and educational purposes.

The Kingdom of Saudi Arabia’s Vision 2030 has catalyzed one of the world’s most ambitious renewable energy programs, with a target of 58.7 GW of clean energy capacity by the end of the decade. For entrepreneurs and investors, this presents a significant opportunity that extends beyond project development to the industrial backbone required to support it: local, high-efficiency solar module manufacturing.

However, entering this market requires more than just capital; success demands a strategic understanding of which technology will deliver the best performance in the region’s demanding climate and provide a competitive edge in national utility-scale tenders. This analysis outlines the business case for establishing a state-of-the-art production line focused on next-generation TOPCon solar modules, specifically engineered for desert conditions.

The Strategic Advantage of TOPCon Technology in a Desert Environment

For decades, PERC (Passivated Emitter and Rear Cell) technology has been the industry standard. While reliable, it is reaching its physical efficiency limits. For a market as competitive and technically demanding as Saudi Arabia, deploying a superior technology is not just an advantage—it is a necessity for long-term viability.

TOPCon (Tunnel Oxide Passivated Contact) technology offers a critical alternative. Its advanced cell architecture significantly reduces energy losses, delivering higher module efficiency. A standard PERC module might achieve 21.5% efficiency, while a TOPCon module can readily exceed 22.5%.

This efficiency gain has profound implications for utility-scale projects:

-

Higher Energy Yield: A 1.0% absolute efficiency increase can translate to nearly 5% more energy generated over the project’s lifetime.

-

Lower Balance of System (BOS) Costs: More power per module means fewer modules, mounting structures, and cables are needed for the same total project capacity, reducing land and installation costs.

-

Superior Temperature Performance: TOPCon cells have a better temperature coefficient than PERC. In the high ambient temperatures of the Saudi desert, where module surface temperatures can exceed 70°C, TOPCon modules degrade less and produce more power. This superior performance is a crucial factor in calculating the Levelized Cost of Energy (LCOE).

These technical advantages form the basis of the DESERT+ module concept—a solar module engineered with TOPCon technology, bifacial cells, and durable materials (like 2.0 mm glass on both sides) to maximize energy yield and reliability in harsh desert conditions.

Investment Profile for a 500 MW TOPCon Facility

Establishing a solar module manufacturing facility requires a clear understanding of the capital expenditure. Based on current market data and experience from European PV manufacturers’ turnkey projects, a 500 MW high-efficiency DESERT+ (TOPCon) production line represents a balanced investment for entering the Saudi utility-scale market.

A typical investment profile for such a facility is in the range of €25 million to €30 million. This investment can be broken down into three main categories:

-

Production Equipment: This is the largest component, encompassing the highly automated machinery required for a state-of-the-art solar module production line. A TOPCon line also requires specialized equipment for processes that differ from standard PERC manufacturing.

-

Building and Infrastructure: A 500 MW facility typically requires a factory floor space of approximately 10,000 to 12,000 square meters. This space accommodates production areas, warehousing for raw materials and finished goods, and office space.

-

Working Capital and Initial Costs: This category covers the initial procurement of raw materials (cells, glass, frames, etc.), operational ramp-up costs, and personnel training.

While the initial investment for a TOPCon line is moderately higher than for a legacy PERC line, the return on investment (ROI) is projected to be substantially greater. Producing premium, high-performance modules enables stronger profit margins and creates a more compelling value proposition for large-scale project tenders.

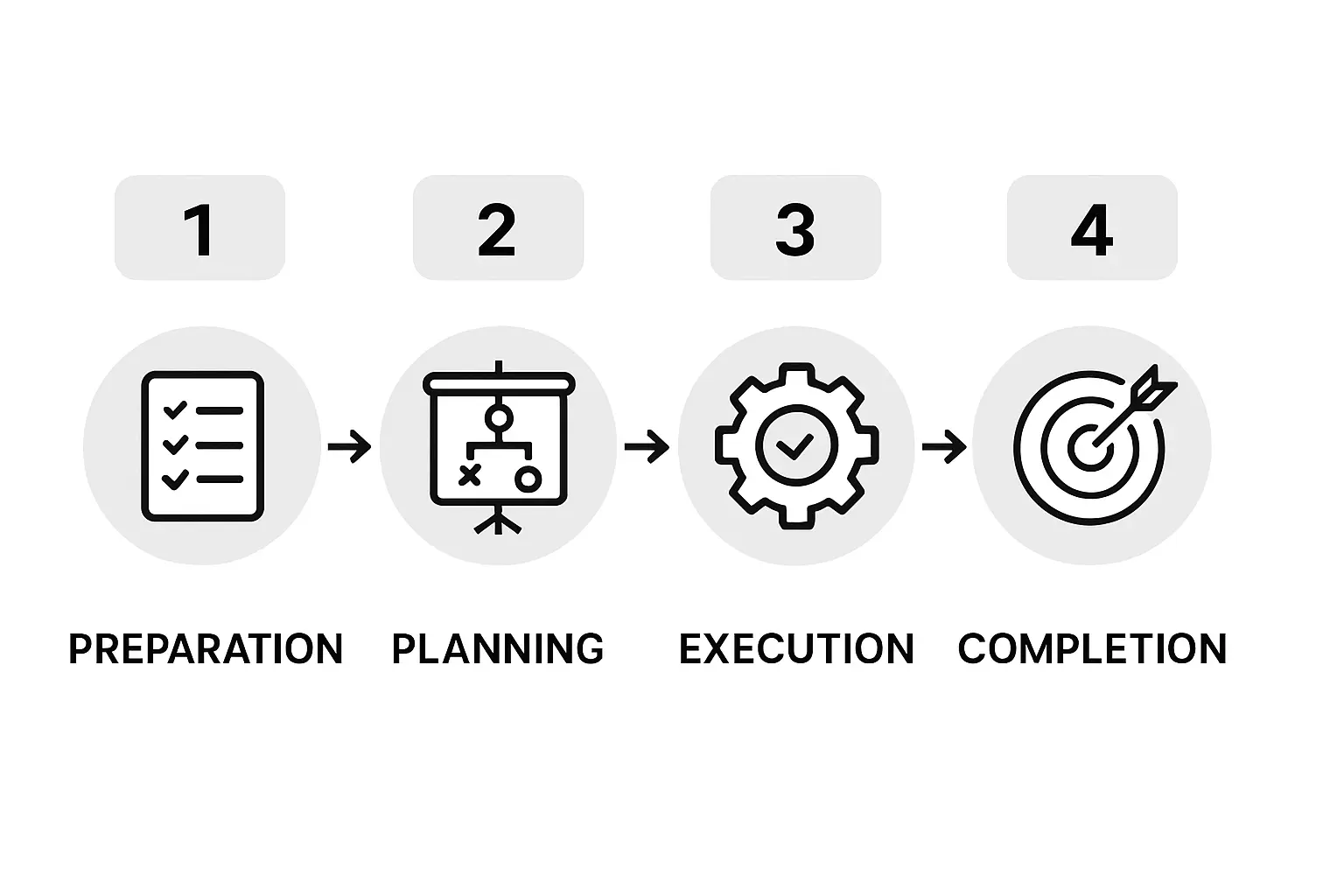

A Phased Execution Plan: From Blueprint to Production in 12 Months

Launching a successful manufacturing operation does not require an investor to be a photovoltaic expert. With a structured, professionally managed execution plan, a new facility can become operational within approximately 12 months.

The process, managed by a technical partner like an established European industrial solutions provider, is typically divided into distinct phases:

-

Phase 1: Feasibility and Engineering (Months 1-3): This involves detailed financial modeling, site selection, finalization of the factory layout, and specification of all solar manufacturing equipment.

-

Phase 2: Procurement and Logistics (Months 4-7): Orders are placed for all machinery, and complex international logistics are managed to ensure timely delivery to the site in Saudi Arabia.

-

Phase 3: Installation and Commissioning (Months 8-11): Expert engineering teams oversee the installation of the production line, connect all utilities, and perform rigorous testing to ensure every machine operates at peak performance.

-

Phase 4: Ramp-Up and Training (Month 12): The first modules are produced. Local staff receive comprehensive training on operations and quality control, ensuring a smooth transition to full-scale production.

This turnkey approach de-risks the project for the investor, ensuring that the facility is built to international standards and is capable of producing certified, bankable solar modules from day one.

Securing a Competitive Position in the Saudi Tender Market

The ultimate goal of a local manufacturing plant is to supply major utility-scale projects tendered by entities like the National Renewable Energy Program (NREP). Success in these tenders depends on two factors: cost-competitiveness and strategic alignment with national objectives.

A local TOPCon facility delivers on both fronts:

-

Lower LCOE: By producing modules with higher efficiency and better temperature performance, the facility offers project developers a product that lowers the Levelized Cost of Energy—a primary metric in tender evaluations.

-

Local Content Requirements: Vision 2030 strongly emphasizes local value creation through programs like the In-Kingdom Total Value Add (IKTVA). A locally manufactured module provides a significant advantage in meeting these requirements, making bids more attractive to government off-takers.

By investing in advanced TOPCon technology, a new entrant can bypass the crowded market for standard commodities and position itself as a premium technology supplier, essential for the next phase of Saudi Arabia’s energy transition.

Frequently Asked Questions (FAQ)

What exactly is TOPCon technology?

TOPCon (Tunnel Oxide Passivated Contact) is an advanced solar cell technology that adds an ultra-thin layer of silicon dioxide (tunnel oxide) and a layer of highly doped polysilicon to the rear surface of the cell. This structure dramatically reduces electron-hole recombination, a major source of energy loss in traditional cells, thereby boosting overall efficiency.

How many employees are required for a 500 MW factory?

A highly automated 500 MW solar module factory typically requires between 150 and 200 employees across all shifts. This includes production line operators, maintenance engineers, quality control technicians, and administrative staff.

Is it necessary to have a technical background to invest in this industry?

No. The success of an investment relies on a strong business plan and partnering with an experienced technical consultant who can manage the entire setup. An EU-based photovoltaic manufacturing solutions partner handles all technical aspects, from factory design to equipment commissioning, allowing the investor to focus on the business strategy.

Why is local manufacturing in Saudi Arabia a better strategy than importing modules?

Local manufacturing offers several distinct advantages. It reduces exposure to international shipping volatility and tariffs, ensures a stable supply chain for national projects, and aligns with Saudi Arabia’s favorable local content policies. Furthermore, it allows for the production of modules specifically optimized for the local desert climate.

What are the main challenges in this venture?

The primary challenges are technical and logistical rather than market-related. They include selecting the right technology, designing an efficient factory, managing international equipment procurement, and training a local workforce. These challenges are effectively mitigated by working with a specialized engineering partner with a proven track record in delivering turnkey production facilities.

Download: Saudi Arabia Solar Manufacturing Case Study (PDF)

Author: This case study was prepared by the

turnkey solar module production specialists at J.V.G. Technology GmbH

It is based on real data and consulting experience from J.v.G. projects

worldwide, including installations ranging from 20 MW to 500 MW capacity.