Disclaimer: This case study represents a composite example derived from real-world

consulting work by J.v.G. Technology GmbH in solar module production and factory optimization. All data points are realistic but simplified for clarity and educational purposes.

In regions facing reconstruction and resource scarcity, the stability of the water supply is paramount. This essential service, however, depends entirely on another, often volatile, resource: energy.

Water pumping, purification, and distribution systems are energy-intensive. Their reliance on unstable electrical grids or costly diesel fuel is a significant vulnerability for national security and public health. This article outlines a strategic, long-term solution: establishing a dedicated, turnkey solar panel factory to secure energy independence for Syria’s water authorities.

The Critical Link Between Energy and Water Security

The Syrian water sector’s demand for electricity has been growing; some estimates suggest a 15% increase in energy consumption is needed to operate water and sanitation systems effectively. When the national grid proves unreliable, the default solution becomes diesel-powered generators—an approach that comes with several fundamental challenges:

- Fuel Scarcity and Volatility: The diesel supply can be inconsistent and subject to extreme price fluctuations, making operational budgeting nearly impossible and threatening service continuity.

- High Operational Costs: Continuous reliance on diesel drains financial resources that could otherwise be invested in infrastructure maintenance and expansion.

- Logistical Complexity: Transporting and securing fuel for hundreds of remote pumping stations is a significant and ongoing logistical burden.

This energy dependency places the entire water infrastructure at risk. Any disruption in fuel supply directly impacts water access for communities and agriculture, with severe humanitarian and economic consequences.

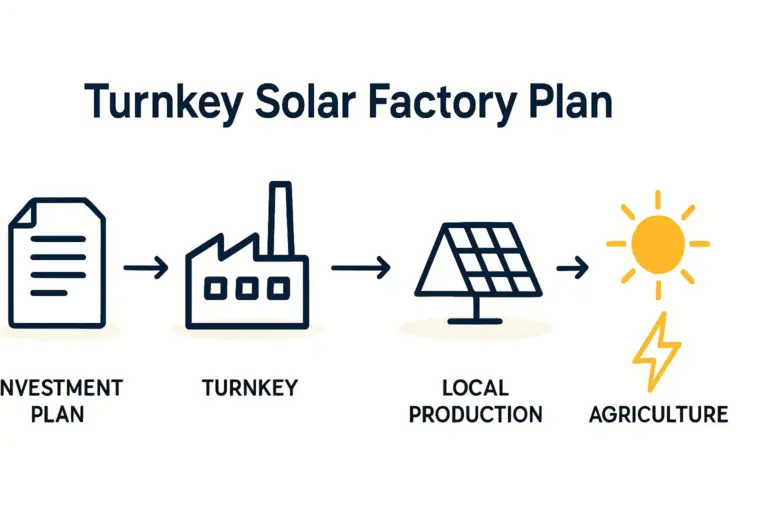

A Strategic Solution: The Dedicated Solar Module Factory

Rather than perpetually purchasing imported solar panels on the open market, a more resilient strategy is to develop domestic manufacturing capacity. A turnkey solar module factory, designed specifically to supply the nation’s water authorities, allows the country to transition from a consumer of technology to a producer of its own energy security.

This approach offers substantial advantages:

- Energy Sovereignty: It ends reliance on foreign supply chains for a critical infrastructure component. The nation controls the production of the technology needed to power its water systems.

- Customization and Reliability: Modules can be designed and built to withstand local environmental conditions—such as high temperatures and dust—and engineered for the specific load requirements of water pumps, ensuring maximum reliability and longevity.

- Economic Development: The project creates skilled jobs, facilitates technology transfer, and builds a new industrial sector. This is a tangible investment in the country’s economic future.

- Long-Term Cost Control: By manufacturing modules locally, water authorities can achieve a stable, predictable, and ultimately lower cost of energy over the 25+ year lifespan of the solar installations.

The Turnkey Project Blueprint

While establishing a solar factory is a complex undertaking, a structured turnkey approach simplifies the process, mitigating risks and ensuring a successful outcome. Based on experience gained from European PV manufacturers’ turnkey projects, a typical project plan unfolds in clear, manageable phases. For a new entrant, understanding how to start a solar factory is the foundational first step.

Phase 1: Feasibility, Partnerships, and Funding

The initial phase focuses on building a robust business case and securing the necessary support. This involves forming a consortium with the relevant Syrian water authorities to establish a long-term offtake agreement. This commitment gives the project a guaranteed primary customer—a crucial element for securing financing from international development banks and humanitarian funds (e.g., UNDP, World Bank) focused on infrastructure resilience.

Phase 2: Factory Design and Equipment Sourcing

A facility with an annual capacity of 20–50 MW is a suitable starting point to meet the demands of the water sector. This scale requires a building of approximately 3,000–5,000 square meters and a workforce of 30–50 employees. The factory layout and selection of solar panel manufacturing machines are tailored to produce high-reliability modules optimized for water pumping applications. An established European industrial solutions provider provides the complete engineering package, from initial layout to final equipment commissioning.

Phase 3: Implementation, Training, and Commissioning

With a clear plan, project implementation can be completed in under 12 months. This phase includes building preparation, machine installation, and, most importantly, comprehensive training of the local workforce. The objective is not merely to build a factory but to empower a local team to operate it efficiently and independently for decades.

Phase 4: Full-Scale Operation and Quality Assurance

Once operational, the factory begins producing modules under strict quality control protocols. The output will directly supply pre-planned solarization projects for water pumping stations, purification plants, and administrative buildings across the country, systematically reducing the sector’s reliance on fossil fuels.

Navigating Government Contracts and International Funding

At its core, a project of this nature is a public-private partnership. Success hinges on aligning the project’s objectives with national priorities and the mandates of international funders.

-

Establish a Public Mandate: The project must be framed as a solution to a national strategic challenge: water security. A formal agreement with the Ministry of Water Resources or a similar body is the cornerstone of the proposal.

-

Develop a Bankable Proposal: A meticulous technical and financial plan must be prepared, detailing everything from production costs to long-term economic benefits. This plan demonstrates project viability to potential investors and funding bodies. Exploring the typical investment requirements for a solar factory is crucial at this stage.

-

Engage Development Partners: International organizations are often keen to fund projects that deliver clear humanitarian benefits, promote sustainability, and build local capacity. A proposal for a solar factory that powers water infrastructure aligns perfectly with these goals.

Why a Turnkey Solution is Essential for This Mission

For critical infrastructure, there is no margin for error. A turnkey approach, managed by a single, a specialized EU engineering partner, offers distinct advantages:

- Unified Responsibility: One partner oversees the entire project from concept to commissioning, eliminating coordination issues between multiple suppliers.

- Guaranteed Performance: The factory is designed as an integrated system, with performance guarantees covering both the production line and the final solar modules.

- Reduced Project Risk: An experienced partner anticipates challenges, navigating the complexities of international logistics, technology integration, and staff training to ensure the project stays on schedule and within budget.

Frequently Asked Questions (FAQ)

What is the typical investment for a 20–50 MW solar factory?

The investment for a complete turnkey line of this capacity typically ranges from €4 million to €7 million, depending on the level of automation and specific technology choices. This includes all production machinery, training, and commissioning.

How many employees are required to operate such a facility?

A semi-automated 20–50 MW factory can be operated effectively with a staff of approximately 30 to 50 individuals, including operators, technicians, engineers, and administrative personnel.

Why build a factory instead of simply importing solar panels?

Importing panels addresses an immediate need but fosters long-term dependency. Building a factory is a strategic investment in self-sufficiency. It localizes the supply chain, creates economic value, and allows for product customization. Crucially, it ensures that a critical national service is not vulnerable to external market shocks or geopolitical instability.

Can this factory be expanded to serve other sectors?

Absolutely. Once the primary demand from the water authorities is met, the factory’s production can be expanded or diversified to supply solar modules for other government needs, commercial projects, or even residential markets, further contributing to the nation’s energy transition.

Download the Syrian Water Infrastructure Solar Case Study (PDF)

Author: This case study was prepared by the

turnkey solar module production specialists at J.V.G. Technology GmbH

It is based on real data and consulting experience from J.v.G. projects

worldwide, including installations ranging from 20 MW to 500 MW capacity.