Qatar’s National Vision 2030 charts a clear course towards economic diversification and sustainable development, with renewable energy as a central pillar. As the nation commissions landmark projects like the 800 MWp Al Kharsaah Solar Power Plant, a strategic question arises: is there an opportunity beyond simply developing solar farms? The answer lies in establishing a local manufacturing base to supply these projects with technology optimized for Qatar’s unique environmental conditions.

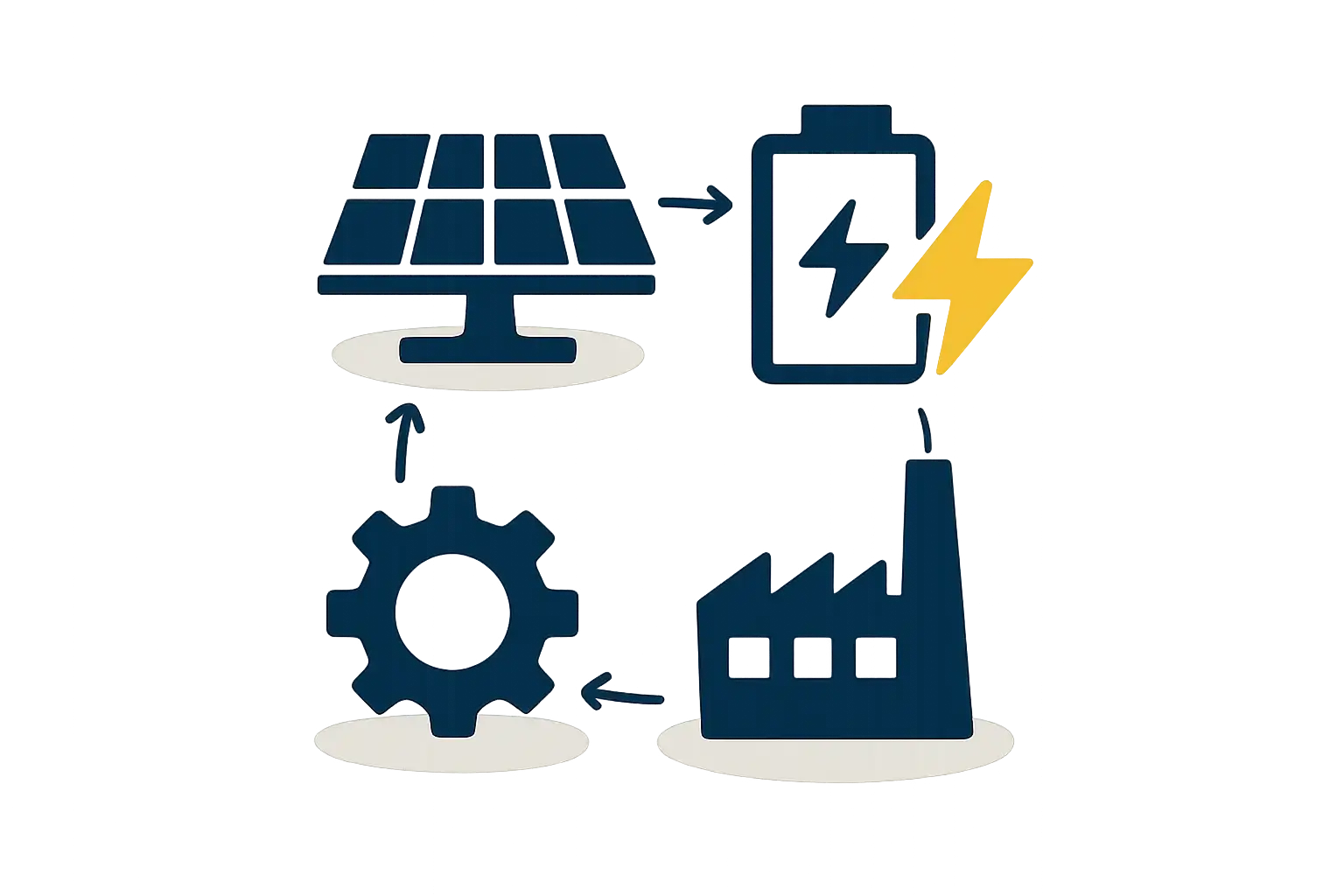

This document outlines the business case for a dedicated production line focused on bifacial solar modules featuring DESERT+ technology. Such a facility would not only align with national strategic goals but also create a significant competitive advantage by producing a product superior to standard imports in the local high-temperature, high-albedo environment.

The Strategic Opportunity: Why Qatar Needs Specialized Solar Manufacturing

Utility-scale solar development in Qatar faces environmental conditions that are both a tremendous asset and a technical challenge. The country’s high solar irradiance is among the world’s best, offering immense potential for energy generation. Yet, the combination of intense heat, airborne sand, and highly reflective ground (high albedo) means that standard solar modules often underperform or degrade faster than specified.

This creates a clear gap in the market. A local factory producing modules engineered for these conditions offers a compelling value proposition to large-scale project developers. Manufacturing in-country also reduces logistical complexity, shortens supply chains, and contributes directly to the nation’s industrial development goals.

Understanding Bifacial and DESERT+ Technology: A Competitive Advantage

Capitalizing on this opportunity requires understanding the technology that offers a distinct advantage in the Gulf region. This business case rests not on producing generic solar panels, but on manufacturing a highly specialized product.

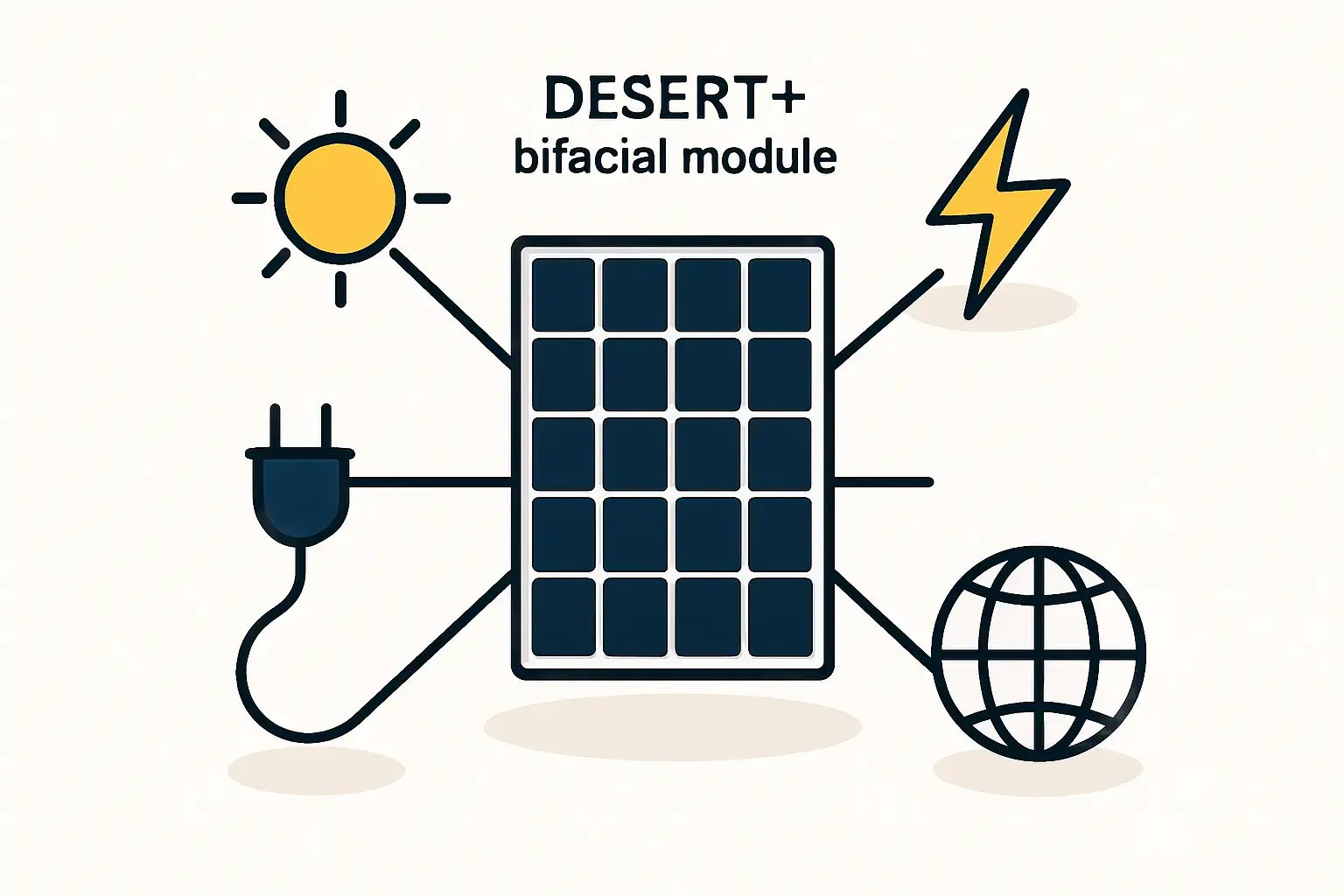

The Power of Two Sides: Bifacial Modules

While a standard (monofacial) solar module captures sunlight on its front side only, a bifacial module has active solar cells on both its front and rear surfaces. This design allows it to capture direct sunlight from above while also absorbing light reflected from the ground.

In an environment like Qatar, where the ground is often light-colored sand or rock, ground reflectivity, or ‘albedo,’ is exceptionally high. This reflected energy, which a standard module wastes, is captured by a bifacial module, resulting in a substantial gain in energy yield—often between 10% and 25%, depending on site conditions. Further information on this topic is available, explaining the specifics of bifacial module technology.

Engineered for Endurance: DESERT+ Technology

DESERT+ is not a single feature but a suite of enhancements engineered for hot, arid climates. Drawing on decades of experience from J.v.G. Technology GmbH in challenging environments, these adaptations include:

- Heat-Resistant Materials: Using specialized encapsulants and backsheets that withstand prolonged exposure to high ambient temperatures without rapid degradation.

- Abrasion-Resistant Glass: Employing glass with a coating that resists pitting and scratching from windblown sand, which helps maintain light transmission over the module’s lifetime.

- Robust Junction Boxes: Utilizing designs and materials that prevent the ingress of fine dust and manage heat more effectively to protect the module’s electrical components.

A module combining bifacial design with DESERT+ technology is a product perfectly tailored for Qatar’s utility-scale solar farms, promising higher energy output and a longer operational lifespan.

Feasibility Study: A 100 MW Turnkey Bifacial DESERT+ Production Line

Establishing a manufacturing facility requires a clear understanding of the investment, infrastructure, and operational parameters. A turnkey approach from an experienced technical partner de-risks the process and ensures adherence to international quality standards from day one.

Initial Investment and Key Metrics

An investor planning for a 100 MW annual production capacity should anticipate the following:

- Estimated Capital Investment: Typically ranges from USD 15 million to USD 25 million for a complete turnkey line, including technology transfer and training.

- Factory Building: Requires a facility of approximately 5,000 square meters, including climate-controlled cleanroom areas for cell stringing and lamination.

- Workforce: A skilled and semi-skilled team of 50–70 employees is needed to operate the line across shifts, including technicians, engineers, quality control, and administrative staff.

Key Production Equipment

A modern, automated production line is key to ensuring high quality and consistent output. The core equipment for a complete solar module production line for bifacial modules includes:

- High-Speed Cell Stringer: A machine that automatically solders solar cells together into precise strings. Bifacial lines require stringers capable of handling double-sided cells without damaging the rear surface.

- Automatic Bussing Machine: Connects individual cell strings to form the complete module matrix.

- Laminator: A critical piece of equipment that uses heat and pressure to encapsulate the solar cells between layers of glass and protective polymers, forming a durable, weatherproof sandwich.

- Sun Simulator / IV Tester: Each finished module is tested under standardized light conditions to certify its power output and electrical characteristics.

The J.v.G. Turnkey Implementation Process

With a structured, expert-led process, the path from investment decision to full-scale production can take less than 12 months. This typically involves:

- Feasibility & Business Plan: Detailed financial modeling and technical validation.

- Factory Layout & Design: Optimizing workflow and cleanroom specifications.

- Equipment Sourcing & Qualification: Procuring and auditing machines from world-class suppliers.

- Installation & Commissioning: On-site setup and calibration of the entire production line by experienced engineers.

- Staff Training & Ramp-Up: Comprehensive training for local operators and technicians to ensure a smooth transition to full production.

- Certification Support: Guidance through the process of obtaining necessary IEC and other international certifications.

The Business Case: Lowering LCOE for Qatar’s Solar Future

The ultimate goal for any power plant developer is achieving the lowest possible Levelized Cost of Energy (LCOE)—the average cost per kilowatt-hour over the plant’s lifetime. The proposed factory contributes directly to lowering LCOE by supplying locally produced, environment-specific bifacial DESERT+ modules.

The higher energy yield from bifacial gain means a solar farm can generate more electricity from the same land area using the same number of modules. This enhanced output, spread over the 25- to 30-year life of the project, significantly lowers the LCOE. Understanding these key performance indicators is crucial for project developers and financiers.

For Qatar, this makes investments in solar infrastructure more financially attractive and accelerates the country’s transition to renewable energy. A local factory is therefore not just an industrial project; it is a critical enabler of more efficient and cost-effective national energy infrastructure.

Frequently Asked Questions

What is ‘albedo’ and why does it matter in Qatar?

Albedo is the measure of how much light a surface reflects. Light-colored surfaces like sand have high albedo, while dark surfaces have low albedo. In Qatar, the high albedo of the desert landscape means a large amount of sunlight is reflected from the ground. This is critical for bifacial modules, as they are designed to capture this reflected light to generate additional power.

Is a 100 MW factory considered large or small?

In a global context of multi-gigawatt producers, a 100 MW annual capacity is considered a medium-sized, boutique factory. This size is ideal for a focused, strategic entry into the market. It is large enough to achieve economies of scale for supplying utility projects in Qatar and the surrounding region, yet agile enough to adapt to new technologies without the massive overhead of a ‘gigafactory.’

How long does it take to set up such a factory?

With a turnkey approach led by an experienced partner like J.v.G. Technology, the timeline from final investment decision to the first certified module coming off the line is typically between 9 and 12 months.

What are the main challenges in operating a solar module factory in a desert climate?

Primary challenges include maintaining strict dust control in cleanrooms, managing cooling for the facility and its equipment, and ensuring a consistent supply of raw materials. A well-designed factory and process flow, integral to the turnkey service, mitigates these challenges from the outset.

Does J.v.G. Technology provide financial modeling support?

Yes, as part of the initial feasibility and business planning phase, J.v.G. Technology provides detailed financial models. These models help investors understand capital expenditure (CapEx), operational expenditure (OpEx), revenue projections, and return on investment based on specific market assumptions.