For family offices and long-term investors, entering a new industrial sector requires calculated risk and strategic foresight. The global shift towards renewable energy presents a compelling opportunity, yet the technical complexity of manufacturing can be formidable. This holds especially true for the solar photovoltaic (PV) industry, a field defined by rapid technological evolution and intricate supply chains.

However, with a structured approach, establishing a sophisticated manufacturing operation is not only achievable but represents a powerful diversification into a future-proof industry. This article outlines a de-risked pathway for non-technical investors, such as family offices, to establish a vertically integrated solar business in Turkey using a turnkey project model.

The Strategic Imperative for Solar Manufacturing in Turkey

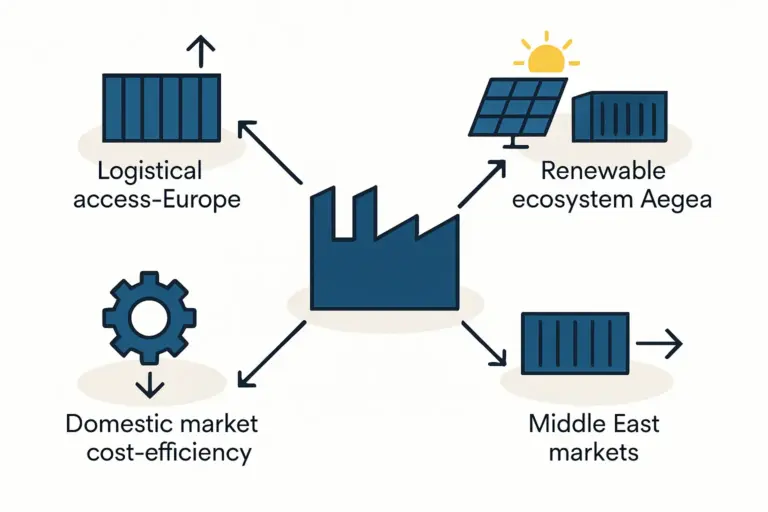

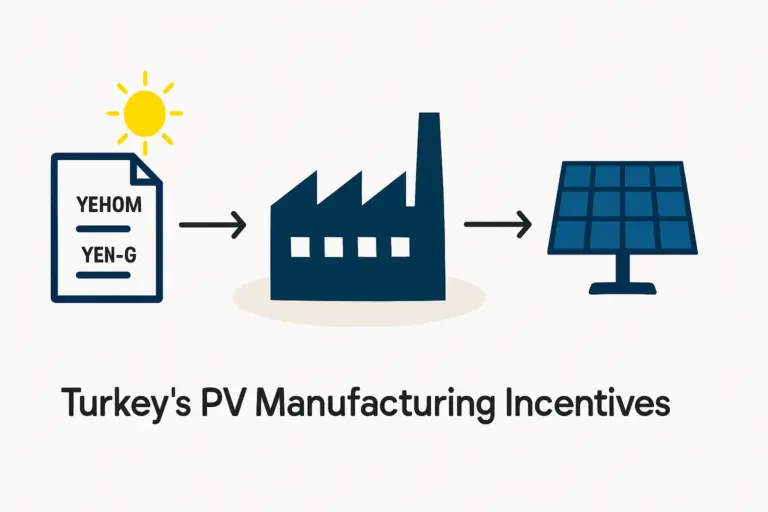

Turkey’s position in the global energy landscape is undergoing a significant transformation. The government has set ambitious targets, aiming to increase its installed solar capacity to 52.9 GW by 2035. These targets create a powerful and sustained domestic demand for high-quality, locally produced solar modules. For an investor, this translates into a clear, long-term market opportunity underpinned by national strategy.

Beyond domestic demand, Turkey’s strategic location offers a distinct advantage for exporting to Europe, the Middle East, and North Africa. Government support mechanisms, such as the Renewable Energy Resources Support Mechanism (YEKDEM), often include incentives for using domestically manufactured components, further strengthening the business case for local production.

Understanding Vertical Integration in Solar Manufacturing

In solar PV, vertical integration refers to a business model where a company controls multiple stages of the production process. Instead of simply assembling solar panels from components purchased from various suppliers, a vertically integrated company produces its own core components.

A typical solar value chain includes:

- Polysilicon to Ingot/Wafer Production: The raw material is melted and formed into highly pure crystalline silicon ingots, which are then sliced into ultra-thin wafers.

- Solar Cell Production: Wafers are processed through a series of chemical and physical treatments to create photovoltaic cells that convert sunlight into electricity.

- Solar Module Assembly: The solar cells are interconnected, laminated with protective materials like glass and backsheets, framed, and fitted with a junction box to create the final solar panel.

By controlling both cell production and module assembly, a business gains significant advantages, including greater control over product quality, insulation from supply chain volatility, and potentially higher profit margins. For a deeper understanding of each component, A Guide to Solar Panel Components offers a valuable overview.

The Challenge: Navigating Complexity as a Non-Technical Investor

While the opportunity is clear, the operational hurdles are significant for those without a background in photovoltaic engineering. Common challenges often deter investors, who see the operational risk as outweighing the market opportunity.

- Technical Complexity: Selecting the right manufacturing technology (e.g., PERC, TOPCon), sourcing reliable machinery, and optimizing production lines require deep domain expertise.

- Project Management: Coordinating the design, construction, and commissioning of a factory is a multi-year undertaking involving dozens of suppliers and contractors.

- Operational Expertise: Recruiting and training a skilled workforce, from line operators to quality control engineers, is critical for success.

- Supply Chain and Logistics: Establishing reliable supply chains for raw materials like polysilicon, glass, and aluminum frames is a complex global endeavor.

These challenges are precisely the problem a turnkey project model is designed to solve.

The Turnkey Solution: A Single Partner for End-to-End Execution

A turnkey solar manufacturing project is an integrated solution where a single, experienced partner takes responsibility for the entire process, from initial concept to a fully operational, staffed, and certified factory. This partner acts as the investor’s expert representative, managing every detail and handing over the ‘keys’ to a running business.

J.v.G. Technology’s turnkey approach de-risks the investment by providing a single point of responsibility and a proven methodology.

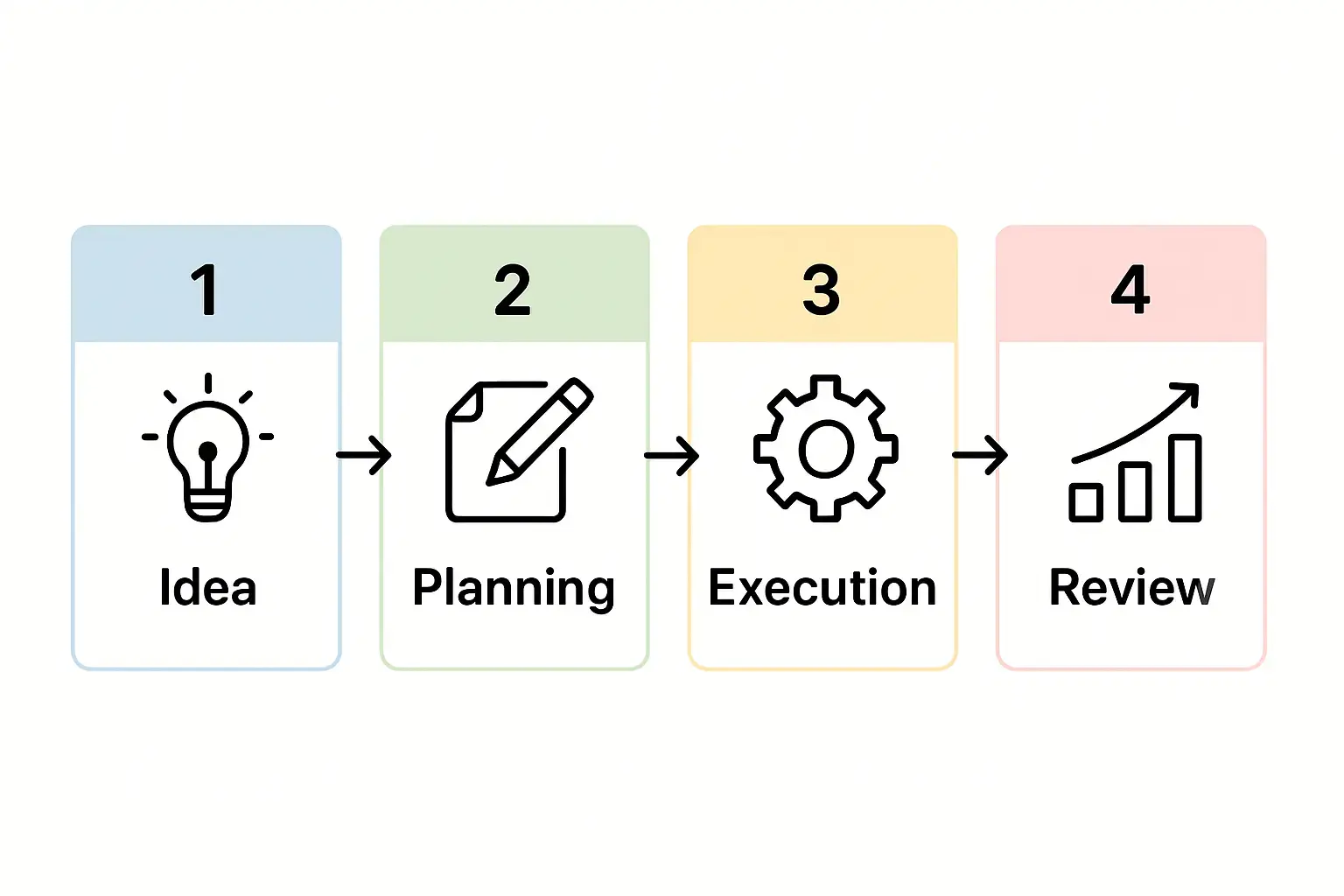

The process is typically broken down into distinct, manageable phases:

Phase 1: Feasibility Study and Business Planning

The project begins with a comprehensive analysis of market dynamics, production costs, and potential revenue streams. This phase delivers a bankable business plan, which is essential for securing financing and making an informed investment decision. Exploring resources like What Is the Investment for a Solar Factory? can provide foundational figures for this stage.

Phase 2: Factory Design and Equipment Sourcing

Based on the business plan, engineering experts design an efficient factory layout. They then leverage their industry network to specify, procure, and audit the best-suited machinery from global suppliers, ensuring compatibility and performance.

Phase 3: Project Implementation and Commissioning

The turnkey partner manages the on-site construction, oversees the installation and calibration of all machinery, and commissions the production lines to ensure they meet the targeted output and quality standards.

Phase 4: Human Resources and Training

A critical and often overlooked step is building the human infrastructure. This involves creating organizational charts, defining roles, recruiting key technical and managerial staff, and implementing comprehensive training programs for the local workforce.

Phase 5: Operational Handover and Support

Once the factory is running smoothly and producing certified products, the project is formally handed over. Often, the turnkey partner provides ongoing support for a transitional period, such as placing an experienced interim manager on-site to ensure a stable transfer of knowledge and operational control.

A Hypothetical Case: A Turkish Family Office’s Venture

Consider a family office in Istanbul with a strong background in real estate development. Seeking to diversify into green technology, they decide to establish a 500 MW vertically integrated facility for cell and module production.

Through a turnkey partnership, the entire project is mapped out over a 24-month timeline. The partner develops the financial models, designs the facility for a site near Izmir, and sources state-of-the-art TOPCon cell and module equipment. During the 18-month implementation phase, the partner’s team is on-site to manage local contractors and oversee machine installation. At the same time, they recruit a local general manager and a core team of engineers who undergo intensive training at a similar facility in Germany.

Upon commissioning, an expatriate production manager from the partner firm stays on for the first year of operation to mentor the local team, stabilize production processes, and oversee the successful completion of TÜV and ISO certifications. The family office, without needing to become technical experts, takes ownership of a fully functional, world-class manufacturing asset poised to capture a significant share of the Turkish solar market.

Frequently Asked Questions (FAQ)

What is the typical timeline for establishing a turnkey solar factory?

For a medium-sized facility (200-500 MW), a realistic timeline from contract signing to the first certified product is typically between 18 and 24 months. This includes planning, procurement, construction, commissioning, and staff training.

Is a technical background required for the investing entity?

No. The primary value of the turnkey model is its ability to enable non-technical investors to enter a technical industry. The turnkey partner provides all the necessary engineering, operational, and project management expertise. The investor’s role is focused on strategic oversight and financing.

How is the investment for a vertically integrated project structured?

The investment is significantly higher than for a simple module assembly line due to the complexity of cell manufacturing equipment. The capital outlay covers machinery, building and infrastructure, initial raw materials, and working capital. For those considering a smaller entry, How to Start a Small Solar Panel Factory provides a useful baseline.

What are the main operational costs after the factory is running?

The primary operational costs are raw materials (silicon wafers, glass, etc.), labor, electricity, and ongoing maintenance. An effective turnkey plan includes detailed financial projections for the first five years of operation to model these costs accurately.

How does a turnkey partner assist with financing?

A credible turnkey partner provides a detailed, bankable business plan and technical specifications that financial institutions require. Their reputation and track record can lend significant credibility to the project, facilitating the process of securing loans and investment.

Conclusion: A Structured Path to Industrial Leadership

For a family office or institutional investor in Turkey, entering the solar manufacturing sector represents a strategic move to build a lasting industrial asset in a high-growth market. The path to vertical integration, while complex, does not have to be an insurmountable challenge.

By leveraging a turnkey project model, investors can effectively delegate the technical and operational complexities to a trusted partner. This de-risked approach transforms a potentially daunting venture into a structured, manageable process, freeing the investor to focus on high-level strategy while building a cornerstone business for the next generation of energy infrastructure.