It may seem counterintuitive to explore new solar opportunities in a country that already generates over 98% of its electricity from renewable sources. Uruguay achieved this milestone through significant investments in wind, solar, and hydropower.

But this success brings a new, more nuanced challenge: how to expand solar capacity without competing for land needed for the country’s other economic powerhouse—agriculture. This dynamic opens up a specialized, high-potential market for entrepreneurs who can produce application-specific solar modules.

This case study explores the business logic of establishing a solar module production line in Uruguay tailored for agrivoltaics (APV), outlining how a local facility can address the agricultural sector’s unique needs and create a durable competitive advantage over imported, standardized modules.

The Challenge of Land Use: A Global Issue with a Local Solution

As solar energy expands globally, a common point of friction is land use. Large, ground-mounted solar farms can occupy vast tracts of land that might otherwise be used for farming or grazing. In a nation like Uruguay, where agriculture—particularly beef, soybean, and dairy—is a cornerstone of the economy, this conflict is especially pressing.

Agrivoltaics offers a direct solution by enabling the dual use of land. These systems mount solar modules on elevated structures, allowing agricultural activities to continue underneath. This synergy not only resolves the land-use conflict but also offers tangible benefits for the farm.

For example, the shade provided by the panels can protect certain crops from excessive heat and reduce water evaporation from the soil. For livestock, this shade offers relief from heat stress, which can improve animal welfare and productivity.

Why Uruguay Presents a Unique Opportunity for Specialized Manufacturing

While importing standard solar modules is always an option, a local manufacturing facility tailored to the agrivoltaics market offers several strategic advantages.

Political and Grid Readiness: Uruguay’s established renewable energy infrastructure means the grid is stable and capable of integrating new, decentralized power sources. The country also has strong political and social acceptance of renewable technology.

Energy Needs of the Agricultural Sector: Modern farms are energy-intensive, requiring power for irrigation pumps, dairy cooling systems, and processing equipment. APV allows farmers to generate this power on-site, reducing their operational costs and reliance on the grid.

New Revenue Streams: Farmers can sell excess electricity back to the grid, creating a valuable new source of income that complements their agricultural output.

Market Evolution: The market is shifting from large, state-driven utility-scale projects to smaller, private, application-specific installations. This trend favors specialized producers who understand and can cater to local needs.

As J.v.G. turnkey projects demonstrate, identifying and serving a local niche like agrivoltaics provides a significant competitive advantage over competitors focused on mass-producing standard modules.

Technical Requirements: The Shift from Standard to Specialized Modules

Producing modules for agrivoltaics is not a matter of simply mounting standard panels on higher racks. The technology itself must be optimized for dual-use environments. A local manufacturer can build a reputation on modules designed with the specific features this market demands.

Bifacial Technology for Enhanced Yield

Agrivoltaics is an ideal application for bifacial modules, which can capture sunlight on both their front and back sides. In an elevated APV array, the back of the module captures sunlight reflected from the ground and crops below, increasing total energy generation by 10–25%. This enhanced output is a powerful selling point for farmers looking to maximize their return on investment. For a detailed technical overview, see What are bifacial solar modules?.

Semi-Transparency and Durability

The type of crop determines the optimal amount of sunlight that should pass through the solar array. While some plants benefit from partial shading, others require more direct light. Semi-transparent modules, often built with a glass-glass structure, allow a controlled percentage of light to penetrate to the crops below.

This glass-glass construction also offers superior durability—a critical feature in an agricultural setting where modules may be exposed to dust from machinery and impacts from farming activities. The choice between constructions is a key decision, as detailed in Glass-Glass vs. Glass-Backsheet Modules: A Guide for Manufacturers.

Adapting the Manufacturing Line for Agrivoltaics

A common concern for prospective manufacturers is whether a specialized market like APV requires a completely different and more expensive factory. The answer is no. The key is production flexibility.

A modern, well-designed solar module production line can produce both standard and specialized modules. The core machinery remains largely the same, but specific equipment choices and configurations enable this versatility. For instance:

- Stringers: The machine that solders solar cells together must be able to handle bifacial cells, which have electrical contacts on both sides.

- Laminators: The laminator must be able to process heavier, more rigid glass-glass module structures in addition to standard glass-backsheet ones.

- Framing Stations: The framing station should accommodate the specific dimensions and structural requirements of APV modules, which may need more robust frames for higher mounting.

A production line with a nominal capacity of 50 MW can often be adapted with minimal changes to its core layout. The primary adjustments are in the lamination and cell-handling stages. For those planning a new facility, The Complete Guide to Solar Module Manufacturing Equipment provides a foundational understanding of the necessary machinery.

The Business Case: Beyond Uruguay

The principles at play in the Uruguayan market are not unique. They serve as a blueprint for entrepreneurs in other regions where agriculture is a dominant industry. Any country with high solar irradiation and a strong agricultural sector—from the plains of Africa to the fields of Southeast Asia—presents a similar opportunity for specialized agrivoltaics manufacturing.

By focusing on a niche with clear local demand, a manufacturer can build a defensible market position, insulated from the intense price competition of the global commodity module market.

Frequently Asked Questions (FAQ)

What is the primary benefit of agrivoltaics for a farmer?

The primary benefit is the dual use of land, which generates two distinct revenue streams: one from agriculture and one from energy generation. Additionally, it can lower farm operating costs by providing on-site power and can improve crop or livestock health through protective shading.

Is a factory for APV modules much more expensive than a standard one?

Not necessarily. The initial investment for a flexible production line capable of producing APV modules is comparable to that of a standard line. The key is selecting machinery—such as stringers and laminators—that can handle both bifacial/glass-glass and standard modules.

Can these specialized modules also be used for other applications?

Yes. Bifacial modules, for example, are increasingly popular in large-scale ground-mounted solar farms and on commercial flat roofs, especially where surfaces are reflective, like light-colored gravel or white roofing material.

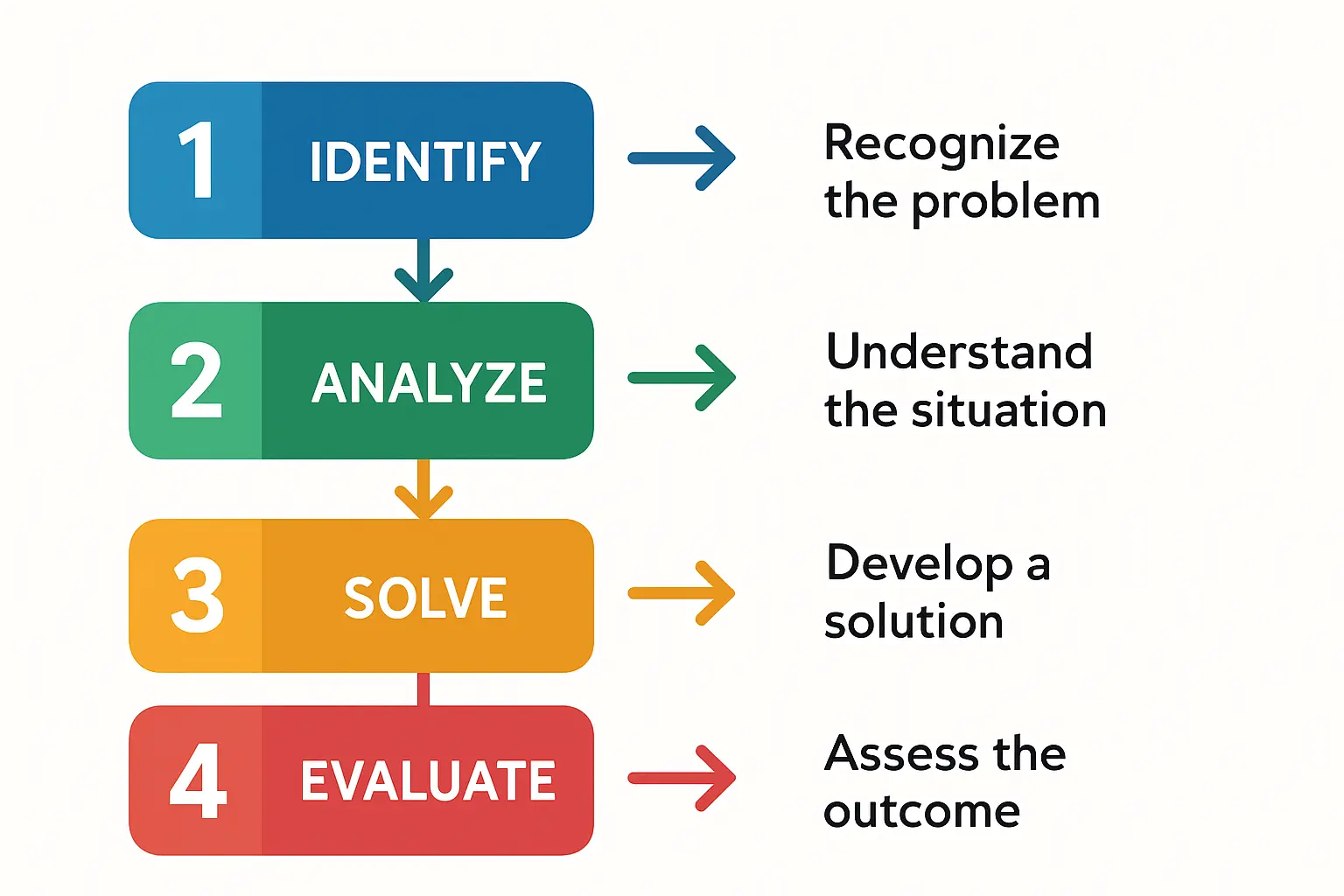

What is the first step to assess this market opportunity?

The first step is a comprehensive feasibility study and a detailed business plan. This analysis should evaluate local demand, grid connection policies, potential government incentives, supply chain logistics, and the specific technical requirements of the target agricultural sector.

Conclusion and Next Steps

The rise of agrivoltaics in Uruguay illustrates a critical lesson for aspiring solar manufacturers: success often comes from specialization, not just scale. By identifying and serving the specific needs of a local industry, an entrepreneur can build a resilient business that provides superior value compared to generic, imported products. This approach transforms a manufacturing facility from a simple assembly line into a strategic solutions provider for a key economic sector.

For those looking to enter this industry, understanding these market nuances is the critical first step. The logical next move is to build a foundational knowledge of what it takes to get started, from planning to execution. A comprehensive guide like How to Start a Solar Module Factory is essential before committing capital and resources to such a significant venture.