Disclaimer: This case study represents a composite example derived from real-world

consulting work by J.v.G. Technology GmbH in solar module production and factory optimization. All data points are realistic but simplified for clarity and educational purposes.

The Sahara Desert receives enough solar energy in a few hours to power all of Europe for a year. This vast potential offers a profound opportunity, particularly for nations like Algeria seeking to secure their future. For entrepreneurs and institutional investors, this is more than an environmental goal—it is a strategic business case for building regional self-sufficiency in food, water, and energy. This article outlines the business case for a local solar module factory in Southern Algeria, specifically to supply the growing agricultural and desalination sectors.

At its core, the challenge is an energy paradox. The very regions with the highest potential for solar power are often the most underserved by reliable electrical grids, hindering the development of critical infrastructure. By shifting the focus from importing finished solar panels to manufacturing them locally, a new model emerges that builds industrial capacity, creates skilled jobs, and directly addresses national security priorities.

The Energy-Water-Food Nexus in the Sahara

Southern Algeria’s development is intrinsically linked to its ability to secure water and produce food. Both endeavors are highly energy-intensive, creating a direct and growing demand for power in off-grid or weak-grid locations.

The Agricultural Power Demand

Modern agriculture in arid regions relies on technologies like center-pivot irrigation to draw water from deep aquifers. While essential for cultivating vast tracts of land, these systems have significant energy requirements.

A single center-pivot irrigation system, common in large-scale desert farming, can require between 50 and 100 kilowatts (kW) of power to operate its pumps and machinery. Supplying this power with diesel generators is costly, logistically complex, and subject to price volatility. Solar power offers a stable, predictable, and ultimately more economical alternative.

Localizing solar module production ensures a dedicated supply chain for these critical agricultural projects, insulating them from the high costs and logistical hurdles of transporting fragile, bulky panels to remote desert locations.

The Desalination Imperative

For coastal and inland communities with access to saline groundwater, desalination is key to water security. The most common method, reverse osmosis (RO), is effective but requires a substantial and constant supply of electricity.

Modern reverse osmosis plants typically consume 3 to 4 kilowatt-hours (kWh) of energy to produce one cubic meter of fresh water. Powering these facilities with locally manufactured solar modules creates a sustainable and resilient water supply—an opportunity especially relevant where the grid is unreliable, as consistent power is crucial for the delicate membranes used in the RO process.

The Strategic Advantage of Local Manufacturing

While importing solar modules may seem straightforward, a local manufacturing facility offers distinct strategic and economic advantages that align perfectly with national development goals.

Overcoming Logistical Barriers

Transporting finished solar modules from coastal ports to project sites deep within the Sahara can be prohibitively expensive, and the risk of damage during transit is high. A factory located closer to the point of use dramatically reduces these logistical costs and complexities, improving project economics and timelines.

Aligning with National Policy

The Algerian government has set ambitious renewable energy targets, aiming for 22 gigawatts (GW) of clean energy capacity by 2030, with 13.5 GW designated for solar PV.

Government tenders and development policies increasingly include local content requirements, giving preference to projects that use domestically produced components. A local factory is therefore not just an operational advantage but a critical enabler for participating in these large-scale national initiatives.

The Turnkey Factory Model

For entrepreneurs and investors without a background in photovoltaics, establishing a manufacturing plant can seem daunting. However, a turnkey solar manufacturing line provides a structured, de-risked path into the industry. This model involves a specialized engineering partner who manages the entire setup process.

The typical scope of a turnkey project includes:

- Feasibility and Planning: Defining the factory’s capacity, technology, and financial model.

- Machine Procurement and Integration: Sourcing, installing, and commissioning the entire production line.

- Process Engineering: Optimizing the pv module manufacturing process for efficiency and quality.

- Training and Handover: Equipping the local workforce with the skills needed to operate and maintain the facility.

Based on experience gained from European PV manufacturers’ turnkey projects, a moderately sized factory with a 20-50 MW annual capacity can be established in a 2,000-3,000 square meter facility and become operational within 12 to 15 months. Such an operation typically requires a workforce of 25 to 40 employees, creating valuable skilled jobs in the region.

The Investment Profile and Execution Plan

Entering the solar manufacturing sector requires a clear understanding of the financial and operational commitments. While specific figures vary, a general framework can be established.

Investment Considerations

The initial capital expenditure covers machinery, facility retrofitting, and operational setup. A detailed financial plan must account for both upfront costs and working capital. For those exploring this opportunity, understanding the typical solar factory investment costs is a crucial first step in the due diligence process.

A Phased Execution Plan

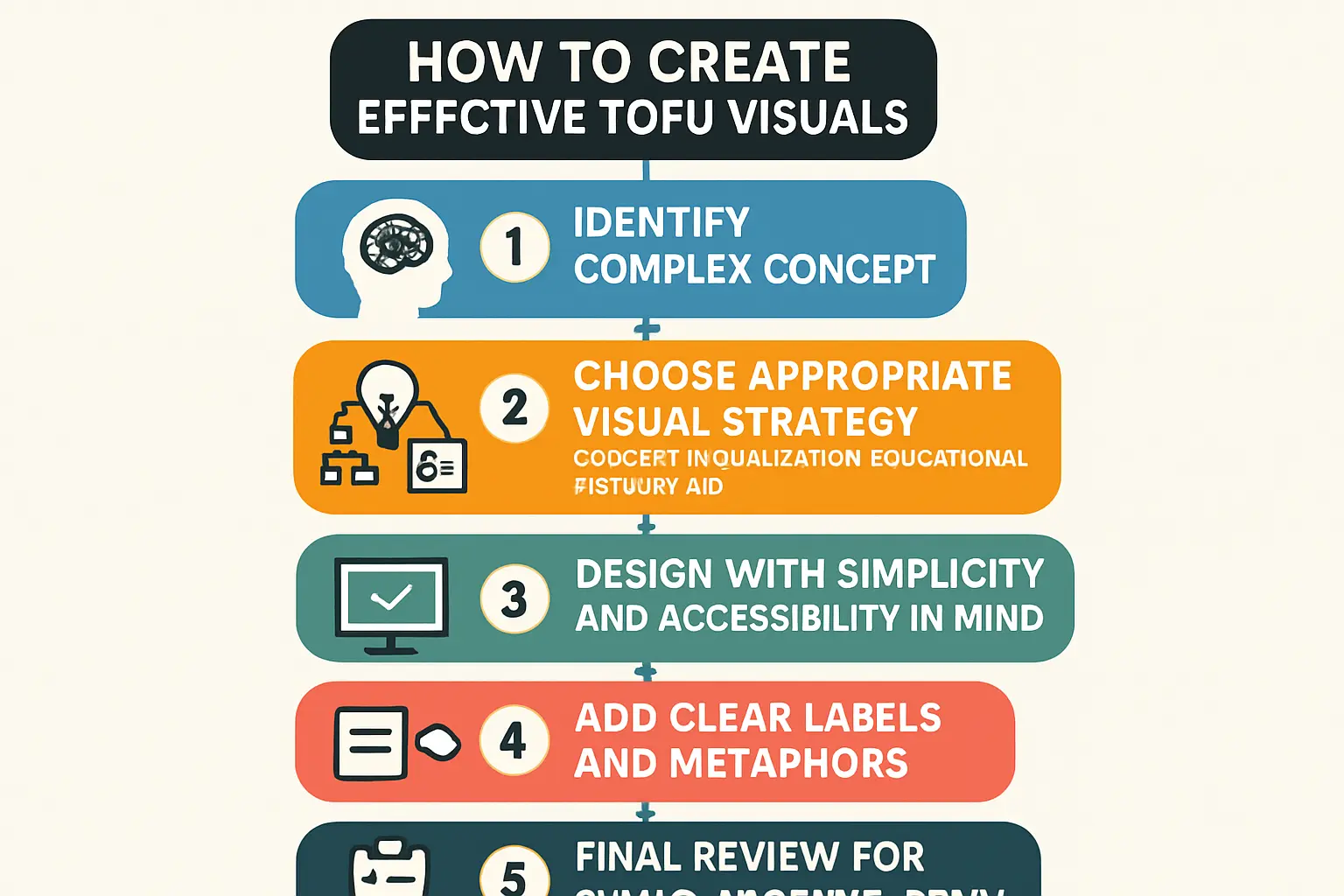

A successful factory launch follows a logical sequence of milestones:

- Phase 1: Business Planning & Feasibility (Months 1-3): Develop a comprehensive business plan, conduct market analysis, and secure initial funding.

- Phase 2: Partner Selection & Engineering (Months 4-6): Select a turnkey engineering partner, finalize factory layout, and begin machine procurement.

- Phase 3: Facility Preparation & Machine Delivery (Months 7-10): Prepare the factory building while equipment is manufactured and shipped.

- Phase 4: Installation & Commissioning (Months 11-13): Install the production line, train staff, and run initial test batches.

- Phase 5: Full-Scale Production & Certification (Months 14-15): Ramp up to full production capacity and obtain necessary product certifications (e.g., IEC).

This structured approach transforms a complex industrial project into a manageable business venture.

Frequently Asked Questions (FAQ)

-

What is the typical starting capacity for a new solar module factory?

For new entrants targeting a specific regional market, a starting capacity of 20 to 50 MW per year is common. This size is large enough to be cost-effective but small enough to manage without requiring an excessive initial investment. -

Is a technical background in photovoltaics necessary to own such a factory?

No. The turnkey model is designed specifically for business professionals and investors. The engineering partner provides the technical expertise for setup and training, allowing the owner to focus on business management, strategy, and market development. -

How many employees are needed to run a 50 MW factory?

A semi-automated 50 MW line typically requires 30 to 40 employees, including operators, technicians, quality control personnel, and administrative staff, working across one or two shifts. -

What are the primary raw materials required for module production?

The key materials include solar cells, tempered glass, encapsulant films (EVA), backsheets, and aluminum frames. A core part of the business plan is establishing reliable supply chains for these components.

Conclusion: A Strategic Investment in Regional Self-Sufficiency

Establishing a solar module factory in Southern Algeria is more than an energy project—it is a foundational investment in the region’s future. It directly addresses the critical needs for food and water security by providing the power for modern agriculture and desalination. By leveraging a proven turnkey model, investors can enter this high-growth sector with confidence, creating a profitable enterprise that also generates significant economic and social value.

For those considering this path, the next logical step is a deeper exploration of the planning and implementation process. Understanding the detailed steps provides the clarity needed to move from a strategic concept to an operational reality. A comprehensive guide on how to start a solar panel factory can serve as an invaluable resource for this journey.

Download the Southern Algeria Solar Manufacturing Case Study (PDF)

Author: This case study was prepared by the

turnkey solar module production specialists at J.V.G. Technology GmbH

It is based on real data and consulting experience from J.v.G. projects

worldwide, including installations ranging from 20 MW to 500 MW capacity.