Disclaimer: This case study represents a composite example derived from real-world

consulting work by J.v.G. Technology GmbH in solar module production and factory optimization. All data points are realistic but simplified for clarity and educational purposes.

Algeria possesses one of the world’s most significant solar resources, with the potential to generate an estimated 4,000 times its current annual electricity consumption. Despite this immense natural advantage, the nation remains heavily reliant on imported photovoltaic technology. This presents both a strategic challenge and an unparalleled opportunity: to transform solar potential into sovereign industrial capacity.

This article presents a comprehensive investment case for establishing a national solar manufacturing hub in Algeria through a Public-Private Partnership (PPP). We detail the strategic imperative, a viable operational framework, and the necessary financial and legal structures for government bodies and institutional investors. The objective is not merely to build factories, but to lay the groundwork for energy independence, economic diversification, and long-term technological sovereignty.

The Strategic Imperative: Why Local Manufacturing is Critical for Algeria

For a nation aiming to achieve its ‘Vision 2030’ and reduce hydrocarbon dependency, a robust domestic solar manufacturing sector is not a luxury—it is a cornerstone of national strategy. Reliance on imported solar modules exposes the country to supply chain volatility, foreign exchange fluctuations, and a loss of potential economic value.

Establishing a local manufacturing hub addresses several key national objectives simultaneously:

-

Energy Security: Domestic production ensures a stable supply of solar modules to meet ambitious national renewable energy targets, such as the planned installation of over 5 GW of solar capacity.

-

Economic Diversification: A manufacturing hub creates a new, high-value industrial sector, reducing the economy’s dependence on oil and gas revenues.

-

Job Creation: The development of a full-scale hub—from module assembly to cell and wafer production—can generate thousands of skilled and semi-skilled jobs, fostering a new generation of technical experts.

-

Value Retention: By manufacturing locally, a significant portion of the investment in solar projects remains within the Algerian economy, stimulating growth in related industries.

The fundamental question is not if Algeria should pursue this path, but how. The scale and complexity of such a venture demand a collaborative model that leverages both public authority and private-sector expertise.

The Public-Private Partnership (PPP) Model: A Blueprint for Success

A Public-Private Partnership provides the ideal structure for a project of this magnitude. It allows for a clear division of responsibilities, aligning the government’s strategic strengths with the operational and technical agility of an experienced private partner. This collaborative framework is the first step toward building a solar panel factory on a national scale.

Defining Roles: Government and Private Sector Synergies

In a well-structured PPP, each partner contributes its core competencies:

The Role of the Public Partner (Government):

-

Strategic Direction & Policy: Setting national renewable energy targets and creating a supportive regulatory environment.

-

Land and Infrastructure: Providing suitable land for the manufacturing hub and ensuring access to essential utilities like electricity and water.

-

Permitting and Approvals: Streamlining bureaucratic processes for construction and operation.

-

Offtake Guarantees: Acting as a primary buyer for initial output through Power Purchase Agreements (PPAs) for national projects, providing revenue certainty.

The Role of the Private Partner (Technical & Operational Expert):

-

Technology & Expertise: Supplying state-of-the-art manufacturing equipment and production know-how.

-

Operational Management: Overseeing the factory’s day-to-day operations, ensuring efficiency, quality control, and output targets are met.

-

Capital Investment: Co-investing in the project, demonstrating long-term commitment.

-

Training & Knowledge Transfer: Developing and implementing comprehensive training programs for the local workforce.

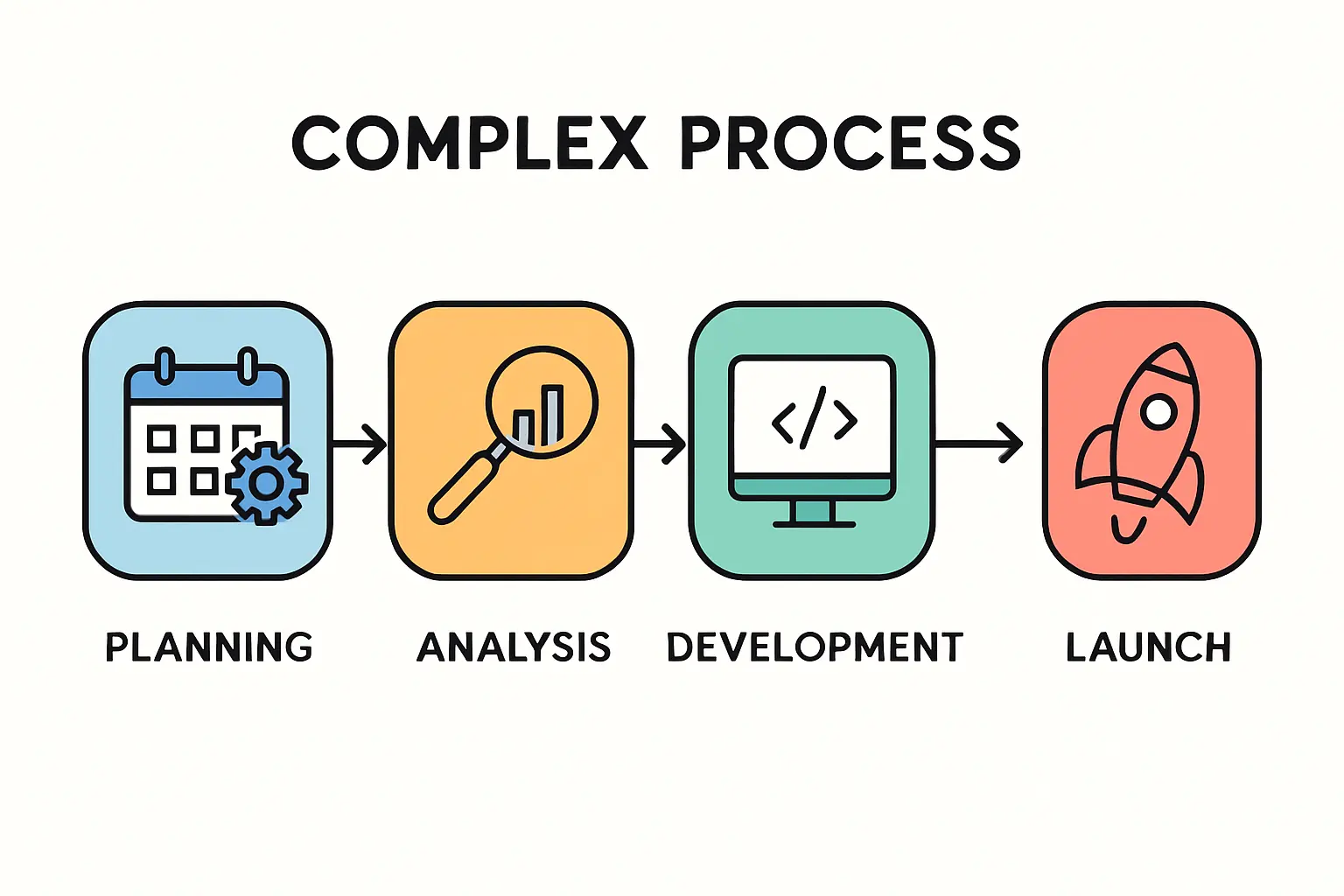

A Phased Approach to Building a National Hub

A national manufacturing hub should not be built in a single, high-risk step. A logical, phased approach allows capacity to scale with market demand and workforce skill development.

-

Phase 1: Solar Module Assembly (500 MW – 1 GW Initial Capacity): The foundational stage involves assembling imported solar cells into finished modules. This phase has a lower technological barrier, allows for rapid market entry, and serves as the primary training ground for the local workforce.

-

Phase 2: Solar Cell Production: Once the module assembly line is stable and profitable, the next logical step is backward integration into cell manufacturing. This step significantly increases local value-add and reduces dependence on international cell suppliers.

-

Phase 3: Ingot, Wafer, and Ancillary Materials Production: The final phase aims for near-complete vertical integration, including the production of silicon ingots and wafers, and potentially encouraging local manufacturing of other key components like solar glass and aluminum frames.

A Turnkey Operational Plan for the Hub

A successful PPP requires more than a legal agreement; it demands a clear and detailed operational blueprint. A comprehensive solar panel manufacturing business plan is the foundational document for all stakeholders.

Core Components of the Manufacturing Hub

The physical plant should be designed for modular expansion. Key facilities include:

-

A fully automated module assembly line.

-

A climate-controlled solar cell production facility.

-

Warehousing for raw materials and finished goods.

-

An R&D laboratory for quality control and future product development.

-

A dedicated Training Academy for workforce development.

Technology Transfer and Workforce Development

The hub’s long-term success hinges on the effective transfer of knowledge to the local workforce. The private partner is responsible for designing and executing a multi-stage training program covering everything from basic machine operation to advanced process engineering and quality assurance. This ensures the facility can be operated sustainably by Algerian talent.

A classroom setting with engineers studying solar panel diagrams on a large screen, reflecting a focus on training and knowledge transfer.

Financial Projections and Investment Structure

The total investment will vary based on capacity and the level of vertical integration. A detailed analysis of solar manufacturing investment requirements is essential. However, a phased approach allows for manageable capital outlays.

Financing for such a project is typically structured through a blended model, combining:

-

Public Funds: Government contributions, often in the form of land, infrastructure, and initial equity.

-

Development Finance Institutions (DFIs): Loans from organizations like the African Development Bank, providing long-term, favorable financing.

-

Private Equity: Investment from the private partner and other institutional investors.

This structure distributes risk and aligns the financial interests of all parties with the project’s success.

The Legal and Regulatory Framework

A clear, stable, and investor-friendly legal framework is non-negotiable. It must provide long-term certainty for all partners.

A close-up shot of two individuals signing a formal agreement, symbolizing the legal framework of a PPP.

Creating an Investor-Friendly Environment

Key legal and policy instruments required include:

-

A robust PPP law: Clearly defining the rights and obligations of each partner, dispute resolution mechanisms, and exit strategies.

-

Investment Protection Guarantees: Protecting private investment against political risks.

-

Tax Incentives: Offering favorable tax conditions during the initial years of operation to encourage investment.

-

Standardized PPAs: Providing clear and bankable power purchase agreements for large-scale solar projects that will use the locally manufactured modules.

Mitigating Risks and Ensuring Long-Term Viability

Any large-scale industrial project carries inherent risks. A successful strategy anticipates and mitigates these challenges from the outset. Partnering with a turnkey solar manufacturing line provider can help design a resilient operational model.

Addressing Common Challenges

-

Supply Chain Volatility: The initial phases will necessarily rely on imported raw materials. The strategy should include diversifying suppliers across different geographic regions and, in later phases, fostering local production of key inputs.

-

Technological Evolution: The solar industry is highly dynamic. The factory must be designed with modularity in mind, allowing for equipment upgrades to accommodate next-generation cell technologies (e.g., TOPCon, HJT) without a complete overhaul.

-

Market Competition: While initial demand will likely come from national projects, the long-term vision should be to produce high-quality, cost-competitive modules for export to regional markets in North and West Africa.

A detailed flowchart illustrating the solar panel manufacturing supply chain, from raw materials to finished products.

FAQ: Foundational Questions for Institutional Stakeholders

-

What is the typical timeline for establishing the first phase?

With a committed PPP structure and streamlined permitting, a 500 MW module assembly line (Phase 1) can be operational within 18 to 24 months of the final investment decision. -

How many jobs can a project of this scale create?

A 1 GW integrated facility (module and cell production) can directly employ between 500 and 800 people. Indirect job creation in logistics, maintenance, and material supply can be two to three times that number. -

What are the primary raw materials, and can they be sourced locally?

Key materials include silicon cells, solar glass, aluminum frames, and encapsulant films (EVA/POE). While high-purity silicon and cells would initially be imported, there is significant potential to develop local production for glass and aluminum frames, further increasing the domestic value chain. -

How does this project align with Algeria’s national development goals?

The project directly supports Vision 2030 by promoting economic diversification, creating skilled employment, reducing import dependency, and positioning Algeria as a regional leader in renewable energy technology. -

What is the role of a European industrial solutions provider?

An experienced technical partner is responsible for the end-to-end implementation of the manufacturing facility. This scope includes factory design, equipment selection and procurement, process integration, quality control protocols, and the comprehensive training of the local workforce to ensure the plant operates at international standards.

From Vision to Execution: The Path Forward

Establishing a national solar manufacturing hub is a nation-building endeavor. It represents a strategic shift from being a consumer of renewable energy technology to becoming a producer. For Algeria, the combination of immense solar resources, a strategic geographic location, and national ambition creates a powerful case for action.

A well-structured Public-Private Partnership is the most pragmatic and effective vehicle to turn this vision into reality. By combining government support with private-sector expertise, Algeria can build a world-class manufacturing asset that will power its future for decades to come.

Download the Public-Private Partnership (PPP) Solar Case Study (PDF)

Author: This case study was prepared by the

turnkey solar module production specialists at J.V.G. Technology GmbH

It is based on real data and consulting experience from J.v.G. projects

worldwide, including installations ranging from 20 MW to 500 MW capacity.