Investors considering a new solar manufacturing venture often focus first on machinery, location, and capital. Experience shows, however, that the most critical factor for long-term success is the quality and composition of the local workforce.

In a high-skill economy like Australia, understanding the labor landscape isn’t just an operational detail—it’s a strategic necessity. While Australia’s high-wage reputation might seem like a barrier, a closer analysis reveals a different picture: a highly educated talent pool, a robust vocational training system, and a deep-seated culture of technical excellence. For entrepreneurs exploring Australia’s growing solar manufacturing opportunities, harnessing this human capital is key to building a competitive and sustainable enterprise.

The Structure of a Modern Solar Factory Workforce

Contrary to the common misconception of hundreds of low-skilled assembly workers, a modern automated facility operates with a much leaner, more skilled team. This workforce is typically segmented into three core groups.

1. Production Operators

These are the hands-on personnel responsible for overseeing specific stages of production. They manage material loading, monitor machine performance, and conduct initial quality checks. While extensive formal education isn’t always required, strong attention to detail and the ability to follow precise technical protocols are essential.

2. Technicians and Engineers

This group forms the technical heart of the factory. It includes:

-

Maintenance Technicians: Responsible for the upkeep, troubleshooting, and repair of the sophisticated machinery on the solar module production line.

-

Process Engineers: Tasked with optimizing production flow, improving efficiency, and ensuring the manufacturing process meets all quality standards.

-

Quality Control Specialists: Conduct detailed material and product testing at various stages, from incoming raw materials to the final module inspection.

3. Management and Administration

This team oversees the facility’s overall operations. It includes roles such as the Plant Manager, Production Supervisor, and staff for logistics, human resources, and finance. These positions require a blend of technical understanding and strong business management skills.

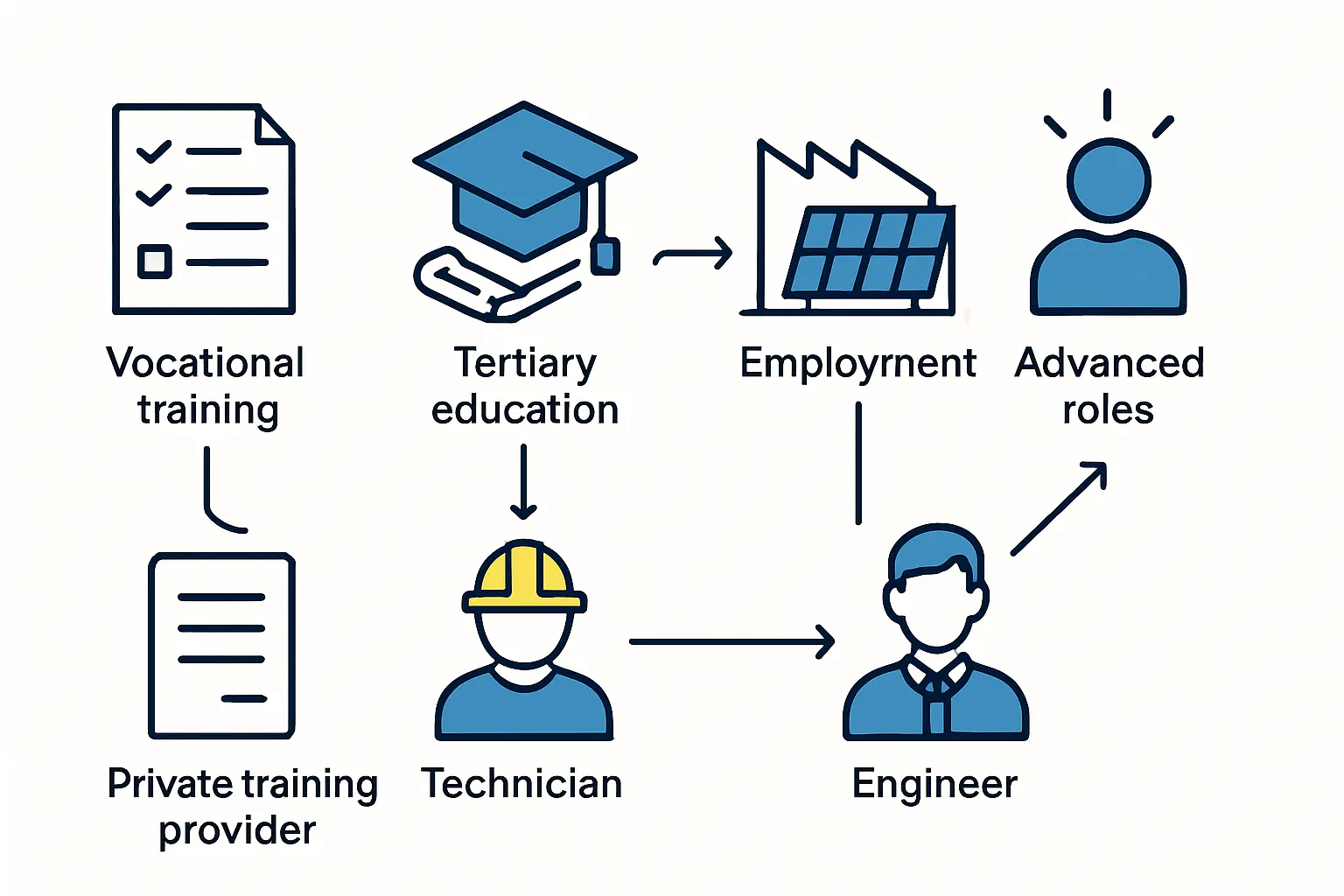

Sourcing Talent: Australia’s Educational and Industrial Landscape

Australia has a well-developed ecosystem for nurturing the talent required for advanced manufacturing. A successful recruitment strategy will draw from two primary educational pillars.

University Graduates: The Engineering Core

Australia is home to world-renowned universities with exceptional programs in engineering, materials science, and renewable energy. Institutions like the University of New South Wales (UNSW) and the Australian National University (ANU) have been at the forefront of photovoltaic research for decades. Graduates from these programs are ideally suited for roles as process engineers, R&D specialists, and quality assurance managers, bringing cutting-edge knowledge to the factory floor.

Vocational Training: The Technical Backbone

The Technical and Further Education (TAFE) system is a national network of institutions providing vocational training. TAFE graduates possess the practical, hands-on skills essential for technician roles.

While their direct experience in solar manufacturing may be limited, their skills are highly transferable from adjacent industries like:

- Advanced Manufacturing

- Automotive Production

- Electronics and Semiconductor Industries

- Mining Technology (Mechatronics and Automation)

This industrial base provides a ready pool of technicians who can be retrained for the specifics of solar module production. Based on experience from J.v.G. turnkey projects, a well-structured training program can bring a skilled technician from an adjacent field up to speed within a few months.

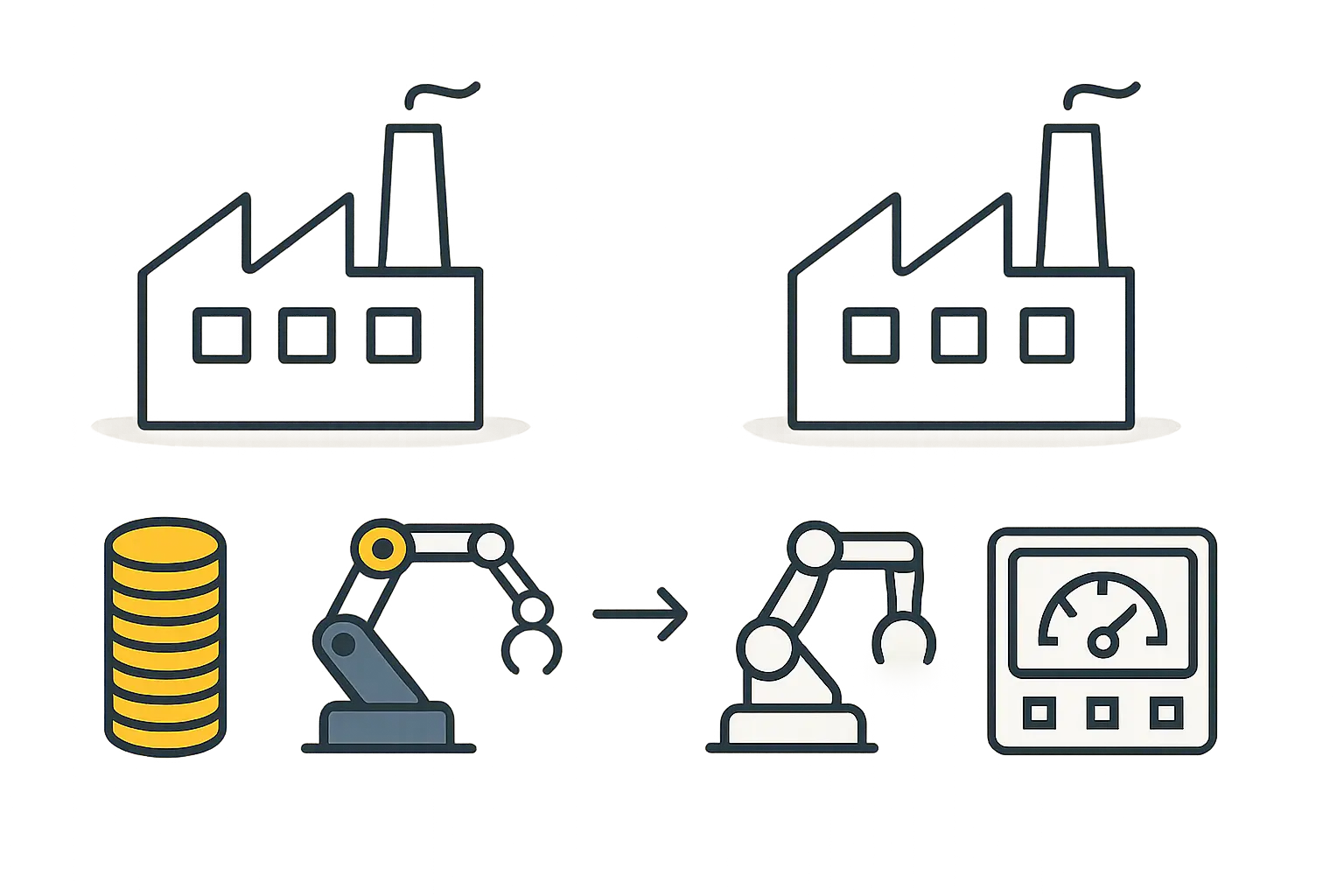

Managing Labor Costs Through Automation and Efficiency

The primary concern for investors in Australia is managing labor costs. The solution lies not in seeking lower wages but in maximizing productivity through automation. Modern solar production lines are heavily automated, particularly in processes like cell stringing, bussing, and lamination.

This high level of automation fundamentally changes the labor equation. It shifts the focus from a large manual assembly workforce to a smaller, more skilled team of technicians who can operate and maintain these complex systems. This approach reduces the number of employees per megawatt of annual capacity, directly mitigating the impact of higher individual wages.

The strategic advantage is clear: a highly automated facility run by skilled local technicians can achieve superior quality control and operational uptime, ultimately leading to a more competitive product.

A Realistic Look at Labor Costs in Australian Solar Manufacturing

Although salary levels in Australia are higher than in many traditional manufacturing hubs, labor doesn’t represent the largest portion of a solar factory’s operational expenditure (OpEx). Raw materials, particularly solar cells and glass, typically make up the most significant cost.

Labor costs must be viewed in the context of the total factory investment and its operational budget. A skilled workforce, though more expensive per hour, leads to lower material wastage, reduced machine downtime, and higher product reliability—all of which have a direct, positive impact on the bottom line.

As this illustrates, when planned correctly, labor costs are a manageable part of the overall OpEx. Investing in skilled personnel is an investment in quality and efficiency.

Frequently Asked Questions (FAQ)

How many employees are needed for a 50 MW solar factory?

A modern, semi-automated 50 MW facility typically requires between 25 and 40 employees, depending on the number of shifts. This usually includes around 15-25 production operators, 5-8 technicians and engineers, and 5-7 management and administrative staff.

Is prior solar industry experience essential for all roles?

No. While experience is valuable for key leadership roles like the Plant Manager or Head of Engineering, most positions can be filled by individuals with transferable skills. A structured training program, often included in turnkey factory solutions, is designed to bridge this knowledge gap.

What is the typical ramp-up and training time for a new team?

A core team of engineers and lead technicians should be hired 3-6 months before the production line is commissioned. They may undergo intensive training, sometimes at the machine supplier’s facility overseas. Production operators can typically be trained on-site over a period of 4-8 weeks as the factory begins its ramp-up phase.

Are there government subsidies for hiring or training in the renewable energy sector?

Australian federal and state governments frequently offer programs to support job creation and skills development in strategic sectors like renewable energy manufacturing. Investors should investigate current initiatives through bodies like the Australian Renewable Energy Agency (ARENA) and state development agencies.

Your Next Steps in Workforce Planning

Building a solar factory in Australia is less about finding cheap labor and more about cultivating skilled talent. The country offers a robust foundation of engineering expertise and technical skill that, when combined with modern automation, can create a globally competitive manufacturing operation.

The next logical step for a prospective investor is to develop a detailed human resources and training plan. This plan should be a core component of the initial business case, outlining recruitment strategies, training schedules, and projected labor costs.

Ready to build your detailed workforce plan? The structured e-courses on pvknowhow.com offer expert modules on workforce planning, operational cost modeling, and factory management to guide your investment.