Many successful entrepreneurs who identify a promising market like solar manufacturing soon face a common hurdle: the perception of European bureaucracy. The image of complex regulations and lengthy administrative processes can seem daunting, especially for investors from outside the EU.

But what is often perceived as a barrier is actually a framework designed for stability, quality, and long-term success. Austria’s regulatory environment isn’t an obstacle course; it’s a clear, predictable pathway for building a reputable and valuable manufacturing operation.

This guide provides a comprehensive overview of the key legal, environmental, and operational standards for establishing a solar module factory in Austria. It is designed to demystify the process for business professionals, transforming regulatory requirements from abstract challenges into manageable components of a robust business plan. Understanding this landscape is the first step toward leveraging Austria’s position as a strategic hub for high-tech manufacturing in the heart of Europe.

Understanding the Austrian Regulatory Framework

Austria operates under a federal system, meaning regulations are set at both the national (Bund) and state (Bundesländer) levels. While federal laws provide the primary legal structure, state authorities are often responsible for implementation and specific permitting. For a solar module factory, investors will focus on regulations in three core areas.

Key Legal Pillars for Manufacturing

-

Trade Law (Gewerbeordnung): This is the foundational law governing all commercial activities. It outlines the requirements for obtaining a trade license (Gewerbeberechtigung), which is mandatory to operate any business, including manufacturing.

-

Building Codes (Bauordnung): Each of Austria’s nine states has its own building code. These regulations govern everything from the structural integrity of the factory building to fire safety and energy efficiency standards.

-

Environmental Law: A comprehensive set of federal and EU-level laws governs the environmental impact of industrial operations. This includes waste management, water usage, and emissions, ensuring that production aligns with Europe’s high environmental standards.

Navigating these pillars is more straightforward than it might seem. With a structured approach, the process becomes a clear sequence of steps. Our guide on how to start a solar factory provides more detail on planning this journey.

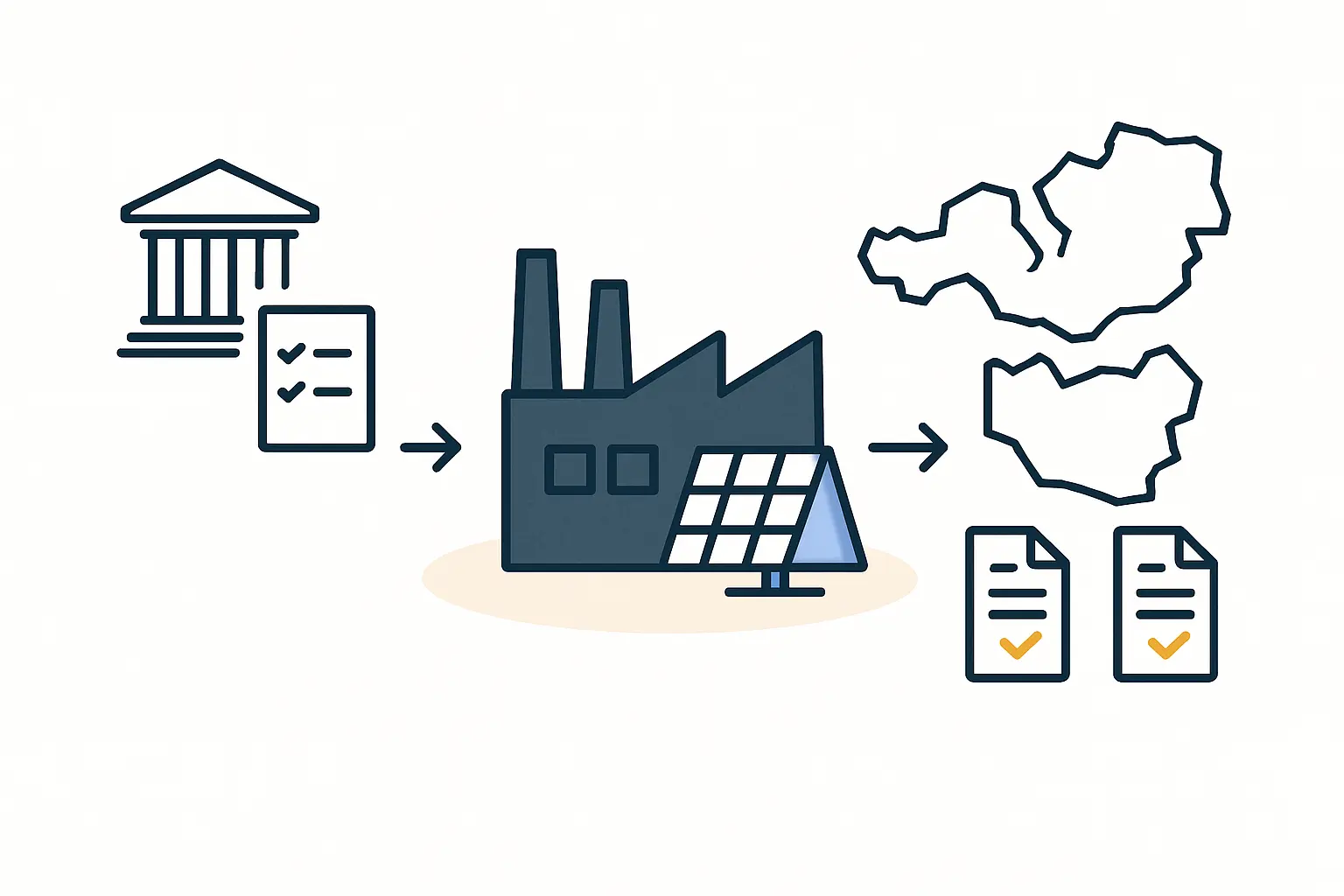

The Core Permitting Process: A Step-by-Step Overview

Establishing a solar manufacturing facility in Austria requires a sequence of approvals. While timelines can vary based on project scale and location, the process is logical and well-documented.

Step 1: Business Registration and Legal Entity Formation

The first step is establishing a legal entity in Austria. The most common form for international investors is the Gesellschaft mit beschränkter Haftung (GmbH), equivalent to a limited liability company. This process involves registering the company in the Austrian Commercial Register (Firmenbuch) and is typically handled with the support of a local legal or tax advisor.

Step 2: Securing an Industrial Site and Building Permit

Identifying a suitable location is critical. Austria has numerous designated industrial zones with pre-existing infrastructure, which can significantly streamline the permitting process. Once a site is selected, the building permit process begins.

-

Zoning Compliance: The land must be zoned for industrial use (Industriegebiet).

-

Building Application (Bauanzeige/Baubewilligung): A formal application, including architectural plans and technical specifications, is submitted to the local building authority (Bauamt). For a typical 20–50 MW solar module factory requiring a 3,000–5,000 square meter facility, this is a critical stage. The plans must demonstrate compliance with the state-specific building code.

Step 3: The Environmental Impact Assessment (UVP)

An Environmental Impact Assessment, known in German as an Umweltverträglichkeitsprüfung (UVP), is a formal procedure to evaluate the potential environmental effects of a large-scale project. Depending on its production capacity and location, a solar module factory may be required to undergo a full UVP.

The assessment examines:

- Air and Water: Potential emissions and water discharge.

- Waste Management: Protocols for handling production waste, including broken cells, EVA trim, and chemicals.

- Noise Levels: The impact of machinery operation on the surrounding area.

Though thorough, this process ensures the facility meets EU-wide environmental standards, which in turn strengthens its long-term operational license and public acceptance.

Step 4: Operational Permits and Trade License

With building and environmental clearances secured, the final step is obtaining the trade license (Gewerbeberechtigung) for manufacturing. The trade authority verifies that the facility, equipment, and designated personnel meet all legal requirements for safe and compliant operation. This license provides the final authorization to begin production.

Key Compliance Standards for Solar Module Production

Beyond the initial setup, ongoing operations must adhere to specific product and safety standards to access the European market. These standards are not just regulatory hurdles; they are hallmarks of quality that build customer trust.

Product Certification: CE Marking and IEC Standards

To be sold anywhere in the European Economic Area (EEA), solar modules must bear the CE mark. This mark is a self-declaration by the manufacturer that the product meets all relevant EU safety, health, and environmental protection requirements.

Adherence to International Electrotechnical Commission (IEC) standards is also crucial, serving as the global benchmark for quality.

- IEC 61215: Tests the design and performance of crystalline silicon modules.

- IEC 61730: Covers module safety qualifications, including electrical and fire safety.

Achieving these certifications is essential for market credibility and a core part of setting up the quality control systems within the factory. Our guide to solar panel manufacturing machines explains how modern equipment helps ensure compliance with these standards from day one.

Environmental, Health, and Safety (EHS) Compliance

Austria has stringent regulations for workplace safety. This includes mandatory training, protective equipment, and clear protocols for handling materials. Compliance with the EU’s Waste Electrical and Electronic Equipment (WEEE) Directive is also crucial. This directive governs the collection and recycling of end-of-life solar modules, making producers responsible for their products’ entire lifecycle.

Common Challenges and How to Prepare

Drawing on experience from J.v.G. turnkey projects in Europe, entrepreneurs should anticipate and plan for a few key challenges:

-

Timelines: The full permitting process, from site selection to operational license, can take between 9 and 18 months. Building this timeline into the solar factory investment requirements from the outset is crucial for realistic financial planning.

-

Local Expertise: Engaging local architects, environmental consultants, and legal advisors who are fluent in German and familiar with state-level authorities is essential for a smooth process.

-

Documentation: Austrian authorities require precise and detailed documentation. A disciplined approach to record-keeping and application preparation is key to preventing significant delays.

Proactive planning and expert guidance are the best ways to manage these challenges, turning potential hurdles into a predictable project management exercise.

Frequently Asked Questions (FAQ)

How long does the entire permitting process typically take in Austria?

For a mid-sized factory (20–50 MW), a realistic timeline is 12–18 months from the start of the planning phase to receiving the final operational license. Projects in pre-zoned industrial parks may be faster.

Do foreign investors face different regulations than local ones?

No. Austrian law treats foreign and domestic investors equally. The requirements for establishing a business, obtaining permits, and complying with regulations are the same for all parties.

Are there government incentives for setting up a green-tech factory?

Yes, both Austria and the EU offer various grants, tax incentives, and low-interest loans for projects in the renewable energy and green technology sectors. These opportunities should be explored early in the business planning phase.

What kind of professional support is essential for this process?

A typical project will require a team of local experts, including a business lawyer (for company formation), a tax consultant, an architect (for building plans), and an environmental consultant (for the EIA process).

Conclusion: A Framework for Success

Establishing a solar module factory in Austria involves a detailed and rigorous regulatory process. Yet this process is defined by clarity, predictability, and a commitment to high standards. For the discerning investor, these regulations are not a liability but an asset, ensuring that the final operation is safe, sustainable, and capable of producing a world-class product for the European market.

With proper preparation and expert guidance, navigating this landscape becomes a straightforward part of the journey. The next logical step for any serious entrepreneur is to translate these requirements into a detailed financial model. Understanding the costs associated with compliance is fundamental to building a comprehensive and successful business plan.