An advanced production line is often seen as the heart of a solar module factory, but the skilled team operating it ultimately determines its output and quality. For entrepreneurs exploring new manufacturing locations, understanding the local human resource landscape is as critical as analyzing machinery specifications. Austria presents a compelling case, but one that requires a nuanced understanding of its labor market, where high costs are directly linked to high productivity and technical excellence.

This analysis examines the Austrian workforce, from the availability of skilled labor and prevailing wage structures to the robust educational systems that support the advanced manufacturing sector.

The Foundation of Austrian Technical Expertise

Austria’s strength in solar manufacturing does not exist in a vacuum. It is built upon a deep industrial heritage in mechanical engineering, mechatronics, and electronics. This legacy has created a mature talent pool with skills directly transferable to the sophisticated processes of solar module assembly.

Professionals in these fields are accustomed to the precision, automation, and quality control standards required in high-value manufacturing, particularly in the automotive and machinery sectors.

A new solar enterprise in Austria, therefore, is not starting from scratch; it is tapping into an existing ecosystem of technical competence. This established base significantly shortens the learning curve for a new workforce and reduces risks associated with process implementation.

Analyzing Labor Costs in the Context of Productivity

For many international investors, European labor costs can seem prohibitive at first glance. A closer examination, however, reveals a more complex picture. The average gross monthly salary for a skilled worker in Austria’s manufacturing sector is approximately €3,800. Ancillary labor costs, such as social security and other contributions, typically add another 30–40% to the base salary.

While these figures are higher than in many other regions, they are accompanied by exceptional levels of productivity, efficiency, and low error rates. Investing in a highly skilled Austrian technician often translates into greater output, reduced material waste, and less downtime for a solar panel production line.

This focus on quality and efficiency can lead to a lower total cost of ownership and a more competitive final product—a crucial factor when considering the overall investment requirements for a solar factory.

Labor Availability and Strategic Recruitment

With high employment rates, competition in Austria for top technical talent is strong. Companies entering the market must compete with established players in the automotive and high-tech machinery industries. This challenge, however, is balanced by several key advantages for a solar manufacturing venture.

The high level of English proficiency among Austrian professionals and younger technicians simplifies communication and integration for international management teams. Furthermore, the growing global importance of renewable energy makes the solar sector an attractive career path for ambitious engineers and technicians.

A successful recruitment strategy highlights the innovation and long-term stability of the solar industry. Attracting the right talent is a core component of evaluating the complete solar manufacturing opportunities in Austria.

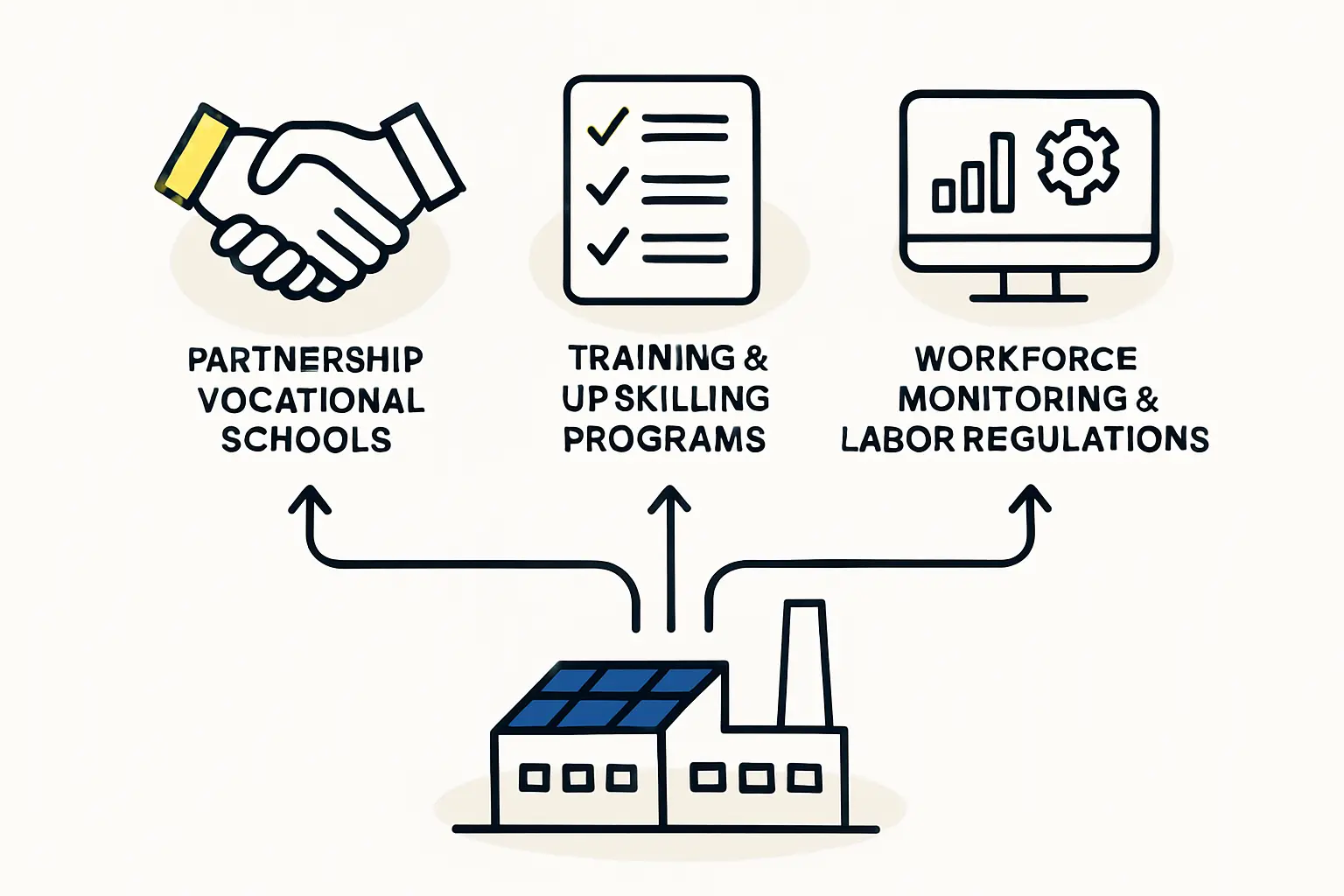

The Dual Education System: A Sustainable Talent Pipeline

One of Austria’s most significant structural advantages is its dual education system. This model combines classroom-based vocational schooling with hands-on, paid apprenticeships inside companies. Students graduate not just with a theoretical understanding but with years of practical, real-world experience.

For a solar panel factory, this system is invaluable. It consistently produces a steady stream of job-ready technicians skilled in mechatronics, automation, and electrical systems—the exact competencies needed on the factory floor. This reduces the burden of basic training for new hires, allowing a company to focus on specialized, process-specific knowledge.

This reliable supply of qualified young professionals is a key factor for long-term operational success.

Leveraging Institutional Support and R&D Networks

New enterprises in Austria are not left to navigate the market alone. The Public Employment Service Austria (AMS) offers various programs to support companies, including wage subsidies for hiring specific groups of job seekers and funding for employee training and qualification initiatives.

Austria’s strong network of technical universities (like TU Wien and TU Graz), applied research institutions (like Fraunhofer Austria), and regional technology clusters (such as Silicon Austria Labs) creates a fertile ground for innovation. Locating a factory near these hubs provides direct access to cutting-edge research, a pool of highly educated graduates, and opportunities for R&D collaboration. This synergy between industry and academia helps a manufacturing operation remain technologically competitive.

Frequently Asked Questions (FAQ)

What are the key technical skills to look for when hiring in Austria?

The most critical skills are in mechatronics, which combines mechanics, electronics, and computing. Expertise in automation technology, electrical engineering, and quality control management is also highly sought after for modern solar manufacturing facilities.

Is it difficult for a foreign company to navigate Austrian labor laws?

Austrian labor laws are comprehensive and highly structured, providing predictability for both employers and employees. While the system is detailed, it is manageable with support from local legal and HR experts. The clarity of the regulations is often seen as a benefit for long-term planning.

How long does it typically take to assemble a core technical team?

With a well-defined recruitment strategy and a competitive compensation package, a core team of engineers, line supervisors, and senior technicians can typically be assembled within six to nine months. The availability of talent from adjacent industries often accelerates this process.

Can government programs help reduce initial labor costs?

Yes, programs administered by the AMS can provide tangible financial support. These may include temporary wage subsidies for new hires or grants to cover the cost of upskilling the workforce on specific solar production technologies, which can ease the initial financial outlay.

A Strategic View on Workforce Investment

Ultimately, establishing a factory in Austria requires viewing the workforce not as a cost center, but as a strategic investment in quality and innovation. The country offers a stable, predictable labor environment with a highly skilled workforce, backed by a world-class education system and strong institutional support.

While the upfront salary costs are notable, they are offset by the high productivity, technical problem-solving capabilities, and process discipline of the workforce. For the entrepreneur focused on producing high-quality, technologically advanced solar modules, the Austrian labor market provides a solid foundation for long-term success. Understanding this dynamic is a fundamental step for anyone learning how to start a solar module factory.