Entrepreneurs planning a new solar panel factory often focus on production machinery and the final product. Yet, a venture’s success often hinges on a less visible but critical factor: the supply chain.

A state-of-the-art production line is only as effective as the system feeding it raw materials and components. For any new manufacturing facility in Austria, grasping the logistical landscape isn’t just an operational detail—it’s a fundamental strategic advantage.

This guide explores the logistics, sourcing, and supply chain infrastructure in Austria. It explains how to leverage the country’s unique geographic position and industrial capabilities to build a resilient, efficient supply system for a solar module manufacturing plant.

Why Austria’s Geographic Position is a Strategic Asset

Located at the crossroads of Western, Eastern, and Southern Europe, Austria offers more than just a central location. It provides direct access to a sophisticated, integrated logistics network that connects major industrial hubs and ports, forming a powerful foundation for any manufacturing enterprise.

For a solar manufacturer, this central position translates into the efficient movement of both inbound raw materials and outbound finished modules. Austria is integrated into several Trans-European Transport Network (TEN-T) corridors—high-capacity rail and road routes designed for streamlined freight transport across the continent. This infrastructure ensures reliable connections to Europe’s largest markets, including Germany, Italy, and the rapidly growing economies of Central and Eastern Europe.

Austria also has strong connections to southern seaports, particularly the Port of Trieste in Italy. The ‘Sempre Operativo Logistik’ (SOL) project enhances the rail link between Austria and Trieste, creating a highly efficient gateway for components arriving by sea from Asia and other global markets. This route can offer significant time savings compared to northern European ports like Hamburg or Rotterdam.

This strategic positioning is a key consideration detailed in the broader analysis of solar manufacturing opportunities in Austria. It transforms the country from merely a location into a logistical hub.

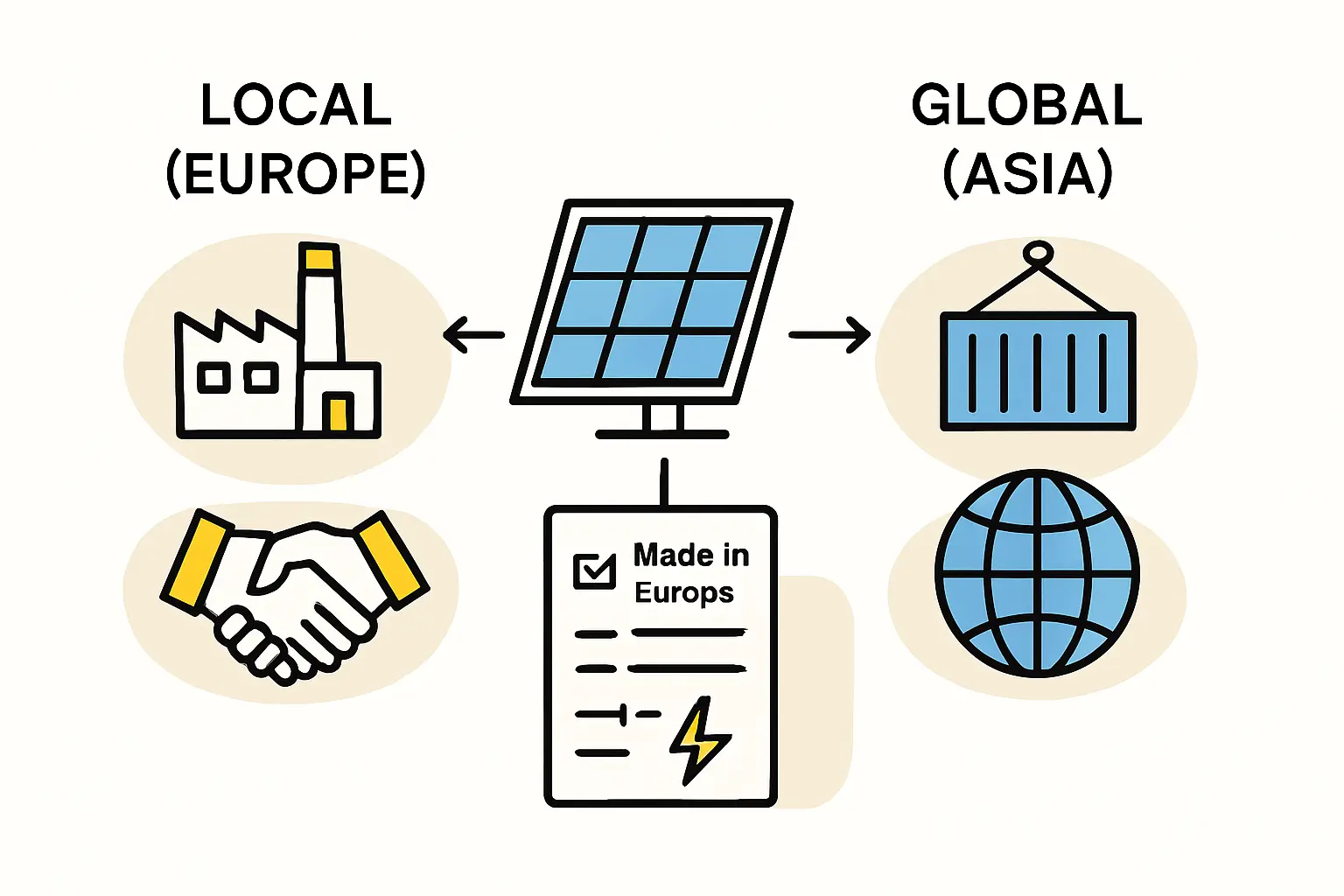

Sourcing Key Components and Raw Materials: Local vs. International

A solar module is an assembly of specialized components. New manufacturers must decide which materials to source locally or within Europe and which to import from global suppliers. Fortunately, Austria and its neighbors offer a robust ecosystem for high-quality components, which can reduce lead times and improve product quality.

Leveraging Local Austrian and European Suppliers

Sourcing components from within Europe brings several advantages: greater supply chain resilience, lower transportation costs, and a smaller carbon footprint for the final product. This can become a strong marketing point, especially for customers who value the ‘Made in Europe’ label.

Austria itself is home to highly specialized industrial firms crucial to solar manufacturing:

- Aluminum Frames: Austria’s strong aluminum industry provides access to high-quality, precision-engineered frames. Sourcing locally avoids the high cost of shipping bulky items from overseas.

- Polymers and Encapsulants: Companies like Borealis, headquartered in Vienna, are global leaders in advanced polymer solutions essential for encapsulants (EVA/POE) and backsheets.

- Specialized Electronics: The country’s respected electronics manufacturing sector can be a source for junction boxes and other minor electronic components.

Beyond Austria, the wider European market offers leading suppliers for other key materials. For example, high-quality backsheets are produced by firms like Isovoltaic (an Austrian company), and world-class inverters are manufactured by Fronius International GmbH in Upper Austria.

Navigating Global Imports for Essential Materials

While Europe has a strong industrial base, certain core components—most notably photovoltaic cells—are predominantly manufactured in Asia. A successful Austrian operation will therefore need a hybrid sourcing strategy that includes efficient global imports.

Importing goods into the European Union involves a structured process governed by common customs regulations. Key considerations include:

- Customs Duties and VAT: Solar cells and other components imported from outside the EU are subject to tariffs and Value-Added Tax (VAT). These costs must be factored into the bill of materials for a solar panel to ensure accurate financial planning.

- Carbon Border Adjustment Mechanism (CBAM): The EU is implementing the CBAM, which places a carbon price on certain imported goods. While solar panels are not yet directly included, related materials like aluminum and glass are. This regulation favors sourcing from regions with lower-carbon production methods, including many European suppliers.

- Logistics Partners: Engaging experienced freight forwarders and customs brokers is critical. These partners manage the complexities of documentation, customs clearance, and inland transportation, ensuring components move smoothly from the port of entry to the factory floor.

The Logistics Framework: From Port to Production Line

Once components arrive at a European port, they must be delivered to the manufacturing facility via a reliable inland logistics network. Austria’s infrastructure is exceptionally well-suited for this task.

Key Logistics Hubs and Infrastructure

Austria’s logistics are centered on major hubs like Vienna, Linz, and Graz. These cities feature advanced intermodal terminals where goods can be efficiently transferred between rail and road.

The national rail operator, ÖBB Rail Cargo Group, is one of Europe’s leading freight carriers, offering extensive connections across the continent. For a solar manufacturer, rail transport is ideal for moving large, standardized shipments of components like glass or solar cells. The country’s motorway network (Autobahnen) is also highly developed, providing reliable ‘last-mile’ delivery by truck directly to the factory.

Based on J.v.G. Technology GmbH’s experience with turnkey projects, a combination of sea freight to a port like Trieste, followed by rail transport to a logistics hub in Austria, and final delivery by truck offers an optimal balance of cost, speed, and reliability.

Import and Export Procedures: A Practical Overview

For a business professional new to European manufacturing, customs procedures can seem daunting. However, the system is highly standardized.

- Intra-EU Trade: Once goods have cleared customs in any EU member state, they can move freely across borders without further checks. This means components sourced from Germany, Italy, or Poland can be delivered to an Austrian factory with minimal administrative burden.

- Non-EU Imports: For goods from outside the EU, a customs declaration is required. Businesses need an Economic Operators Registration and Identification (EORI) number to manage this process. A competent logistics partner will handle these formalities as part of their service.

Building a Resilient Supply Chain Strategy in Austria

The goal is not simply to find the cheapest supplier but to build a resilient, predictable, and cost-effective supply chain. Austria’s location and infrastructure make sophisticated strategies viable.

- Supplier Diversification: A prudent approach is to diversify suppliers. For example, a manufacturer might establish a primary supplier for solar cells in Asia while qualifying a secondary, perhaps European, supplier as a backup to mitigate geopolitical or shipping risks.

- Inventory Management: The efficiency of Austria’s logistics network makes a Just-in-Time (JIT) inventory model feasible. This reduces the need for extensive on-site warehousing, freeing up capital. When planning your solar factory layout, this can allow for more space to be dedicated to production.

- Localization Awareness: While a JIT approach is ideal in a stable environment like Austria, entrepreneurs in regions with less predictable logistics might initially opt for larger safety stocks. The Austrian model, however, demonstrates what is possible with world-class infrastructure.

Frequently Asked Questions (FAQ)

What are the main components I can source within Austria or the EU?

High-quality aluminum frames, junction boxes, specialized polymers for backsheets and encapsulants, and certain electronics can be readily sourced from Austria and neighboring countries like Germany. This reduces lead times and shipping costs.

How do import duties on solar cells from China affect my costs?

Import duties are a significant cost factor that must be included in your business plan. The exact rates can change based on EU trade policy. A customs broker or a consultancy like J.v.G. can provide up-to-date information for financial modeling.

Is rail or road transport better for moving components within Austria?

For bulk materials arriving from a seaport, rail is often more cost-effective and environmentally friendly. For final delivery from a domestic hub to the factory, road transport (trucking) offers greater flexibility. Most strategies use a combination of both.

What is a typical lead time for components sourced from within Europe versus Asia?

Sourcing from within Europe can reduce lead times from over a month (for sea freight from Asia) to just a few days. This enhances production flexibility and reduces the amount of working capital tied up in inventory.

Conclusion: Your Next Steps in Supply Chain Planning

Establishing a solar panel factory in Austria offers compelling advantages that extend far beyond the production floor. The country’s strategic location, world-class logistics infrastructure, and access to a high-quality European supplier base create a powerful ecosystem for success.

A well-designed supply chain is not a background operation; it is a source of competitive strength, enabling a manufacturer to be more agile, resilient, and cost-effective.

A thorough understanding of these logistical factors is a critical part of the initial business plan. The structured modules available through pvknowhow.com provide a detailed framework for evaluating these supply chain variables, helping entrepreneurs make informed decisions from the very beginning.