Disclaimer: This case study represents a composite example derived from real-world

consulting work by J.v.G. Technology GmbH in solar module production and factory optimization. All data points are realistic but simplified for clarity and educational purposes.

An investor considering the solar manufacturing sector often encounters a standard blueprint: a factory reliant on a significant labor force, established processes, and a familiar balance of capital and operational costs.

But for a forward-thinking market like Bahrain, a different model presents a more compelling long-term proposition: the highly automated, data-driven ‘Industry 4.0’ or ‘lights-out’ factory. This approach, while requiring a higher initial investment, is designed to deliver superior financial returns, operational resilience, and a competitive edge that aligns perfectly with the nation’s high-tech ambitions.

This article makes the business case for establishing a state-of-the-art, fully automated solar module production facility in Bahrain. It moves beyond conventional manufacturing to explore a model where machines, data, and intelligent systems converge to create a production environment of unparalleled efficiency and quality.

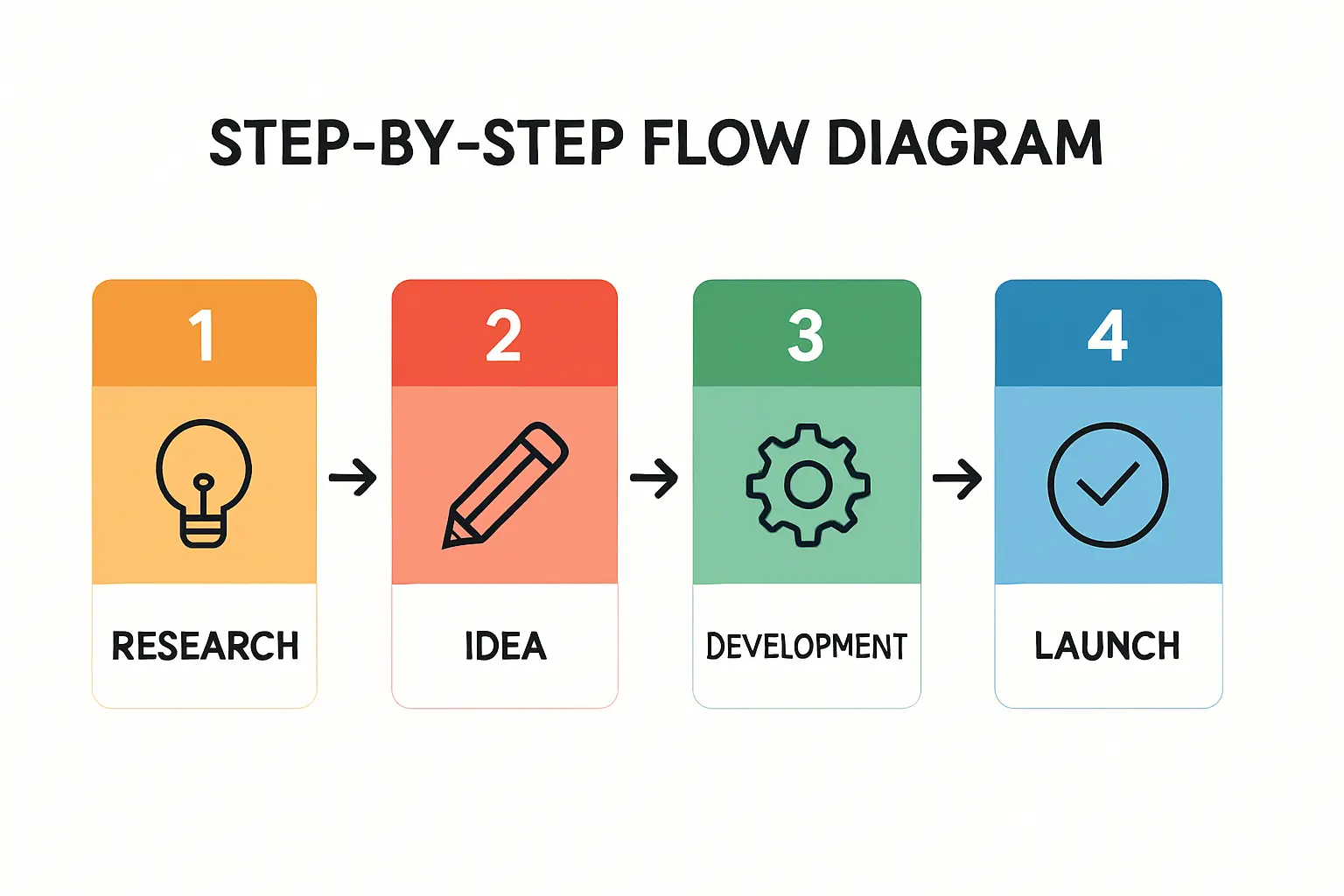

What Defines an ‘Industry 4.0’ Solar Factory?

The term ‘Industry 4.0’ refers to the fourth industrial revolution, characterized by the integration of digital technology into manufacturing. In a solar module factory, this means more than just using robots instead of people; it means creating a fully integrated, self-optimizing ecosystem.

Key characteristics include:

- Total Automation and Interconnectivity: Every machine, from the cell tester to the final laminator, is connected through an industrial Internet of Things (IoT) network. Robotic arms and automated guided vehicles (AGVs) handle all material transport, eliminating manual intervention in the core solar panel manufacturing process.

- Centralized Data-Driven Control: Acting as the factory’s central brain, a Manufacturing Execution System (MES) collects real-time data from thousands of sensors on every machine, tracking metrics like temperature, speed, and material usage.

- Predictive Analytics and AI: Artificial intelligence (AI) and machine learning (ML) algorithms analyze the vast amount of data collected. The system can then predict when a machine needs maintenance before it fails, identify patterns that could lead to defects, and continuously optimize production parameters for maximum yield.

- The Digital Twin: A complete virtual replica of the factory—the ‘digital twin’—is used to simulate changes, such as introducing a new solar cell technology. Processes can thus be perfected virtually before implementation on the physical production line, saving significant time and cost.

Aligning with Bahrain’s Economic Vision 2030

Establishing a high-tech manufacturing facility of this caliber is more than a sound business decision; it is a strategic alignment with Bahrain’s national goals.

Bahrain’s Economic Vision 2030 prioritizes diversifying its economy, with a strong focus on developing a sustainable, high-value manufacturing sector. An Industry 4.0 solar factory directly supports this by:

- Attracting High-Value Investment: Such a facility positions Bahrain as a hub for advanced, clean-energy technology, moving beyond traditional industries.

- Developing a Skilled Workforce: While it reduces the need for manual labor, the factory creates demand for high-skilled roles in engineering, data science, and robotics—precisely the talent pool the Kingdom aims to cultivate.

- Leveraging Logistical Strengths: Bahrain’s strategic location and world-class logistics infrastructure make it an ideal base for exporting high-quality solar modules to the GCC region and beyond.

- Showcasing Technological Leadership: A ‘lights-out’ solar factory would serve as a landmark project, demonstrating Bahrain’s commitment to innovation and attracting further technology-focused foreign direct investment.

The Financial Equation: High CAPEX for Superior Long-Term ROI

The initial Capital Expenditure (CAPEX) for a fully automated factory is admittedly higher—typically 30-40% more than a conventional setup. This premium accounts for advanced robotics, a comprehensive sensor network, and the sophisticated MES software required to integrate and run the facility. This initial outlay is explored through a detailed examination of the investment requirements for a solar panel factory of this type.

However, this higher CAPEX unlocks substantially lower Operating Expenses (OPEX), leading to a much faster and more robust Return on Investment (ROI).

The business case is built on three pillars of operational savings:

- Reduced Labor Costs: A conventional 500 MW factory might require over 200 operators across three shifts. An automated equivalent can run with fewer than 50, primarily skilled technicians and engineers for oversight and maintenance. This dramatically cuts long-term payroll liabilities.

- Minimized Material Waste: Human handling of delicate solar cells inevitably leads to microcracks and breakage, reducing overall yield. Precision robotics handle every cell and module with perfect consistency, cutting material waste to near zero and maximizing output from raw materials.

- Increased Uptime and Throughput: Automated systems can operate 24/7 with minimal interruption. Predictive maintenance alerts ensure issues are addressed before they cause a line stoppage, resulting in higher and more predictable production output compared to lines susceptible to human error and unscheduled downtime.

Based on Expert-led European solar project architecture and modeling, the combination of these factors typically yields a project ROI within 3 to 5 years, with a significantly higher Internal Rate of Return (IRR) over the project’s lifetime compared to a traditional factory.

Operational Excellence as a Competitive Advantage

Beyond the financial metrics, an Industry 4.0 factory delivers a level of operational control that becomes a powerful competitive weapon.

Unmatched Quality and Consistency

In the solar industry, quality is paramount. Bankability—the willingness of financial institutions to fund projects using a specific brand of modules—depends on proven long-term performance and reliability. Automated production lines ensure every single module is manufactured to the exact same high standard. Automated optical inspection (AOI) and electroluminescence (EL) testing at multiple stages catch microscopic defects a human eye would miss, guaranteeing a near-zero defect rate.

Future-Proof Flexibility

The solar industry evolves at a rapid pace. As new cell technologies like TOPCon and HJT emerge with different handling and processing parameters, a software-driven, automated factory offers far greater flexibility. Adjusting a robotic arm’s path or a stringer’s heating profile can often be done via software updates, allowing the factory to adapt to new technologies without costly and time-consuming physical retooling. This agility makes choosing the right solar manufacturing equipment from the start critical for long-term relevance.

The Central Role of the MES

The Manufacturing Execution System is the core of this operational excellence. It provides a single source of truth for the entire facility. Management can view real-time dashboards showing production efficiency (OEE), material consumption, and quality metrics from anywhere in the world. This level of transparency and control is impossible in a conventional factory.

The Premier European Model for Turnkey Industry 4.0 Integration

Achieving this level of seamless automation is a complex engineering challenge. It requires a partner with deep expertise not only in individual machines but in the software and process engineering needed to make them work as a single, intelligent entity.

Projects of this nature are best approached as a complete, integrated system from day one european turnkey engineering team specializes in designing and implementing a turnkey solar production line, selecting and configuring every component to work within a unified MES-controlled environment. This holistic approach ensures that the facility functions as a cohesive, self-optimizing unit from the moment it is commissioned, de-risking the project for the investor.

Frequently Asked Questions (FAQ)

Is a fully automated factory suitable for a new entrant to the solar industry?

Yes, in many ways, it is an ideal model. By embedding process control and quality assurance directly into the system, it reduces operational complexity. This lowers the dependency on finding and training a large, highly specialized operational workforce, which can be a significant challenge in any new market.

What is the typical production capacity for such a facility?

Industry 4.0 models deliver the best economies of scale at higher capacities. They are typically designed for annual production outputs of 500 MW to over 1 GW to fully leverage the efficiency gains from automation.

How does this model specifically reduce material waste?

Waste is reduced through precision and data. Robotic arms handle fragile solar cells with consistent pressure and placement, preventing breakage. If a sensor detects a minor deviation in the lamination process, the system can self-correct in real time, preventing an entire batch of modules from being compromised. The result is a higher yield—more finished A-grade modules from the same amount of raw materials.

What kind of workforce is needed to run an Industry 4.0 factory?

The workforce shifts from manual labor to knowledge workers. The team typically consists of control room operators who monitor the system, maintenance technicians with skills in robotics and electronics, process engineers who analyze data to find optimization opportunities, and IT specialists who manage the network and MES.

Conclusion and Next Steps

For an investor in Bahrain, the choice is not simply between building a factory or not; it is between building a factory for today and a high-tech asset for the future. The Industry 4.0 solar manufacturing model represents a strategic investment in efficiency, quality, and long-term profitability. It is a capital-intensive approach that rewards foresight with market leadership and operational resilience.

While the concept of a ‘lights-out’ factory may seem futuristic, the technology and engineering expertise to build one are available today. The next logical step for a prospective investor is to develop a detailed financial model and feasibility study tailored to this high-automation approach, evaluating the specific costs and returns for a facility in Bahrain.

Author: This case study was prepared by the

turnkey solar module production specialists at J.V.G. Technology GmbH

It is based on real data and consulting experience from J.v.G. projects

worldwide, including installations ranging from 20 MW to 500 MW capacity.