Disclaimer: This case study represents a composite example derived from real-world

consulting work by J.v.G. Technology GmbH in solar module production and factory optimization. All data points are realistic but simplified for clarity and educational purposes.

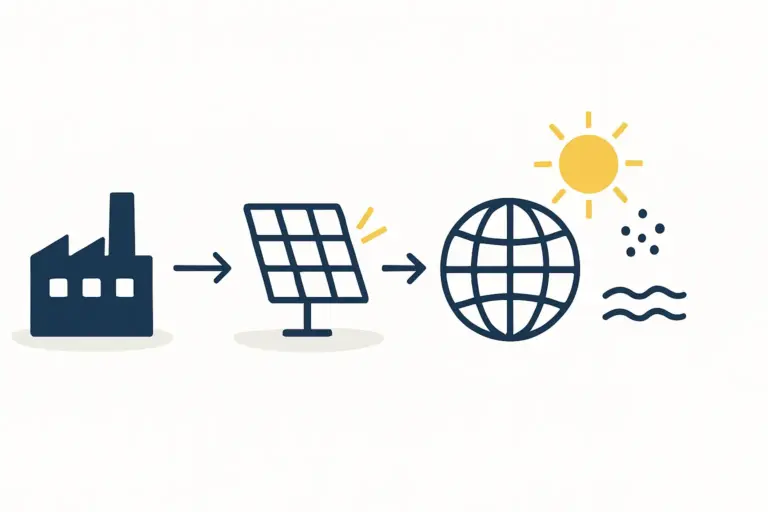

While many new entrants in the solar industry focus on producing standard photovoltaic modules, a more strategic approach often yields greater long-term success. This is especially true in regions with unique environmental conditions and ambitious energy goals.

Instead of competing in the crowded market for conventional panels, a focused strategy targeting a high-value niche can establish a durable competitive advantage. This analysis makes the business case for a specialized solar module factory in Bahrain, focusing on high-performance bifacial and DESERT+ certified modules. It explores how the right combination of strategic location, targeted technology, and expert implementation can create a highly profitable venture that serves the region’s burgeoning utility-scale solar market.

Why Bahrain? A Confluence of Strategic Advantages

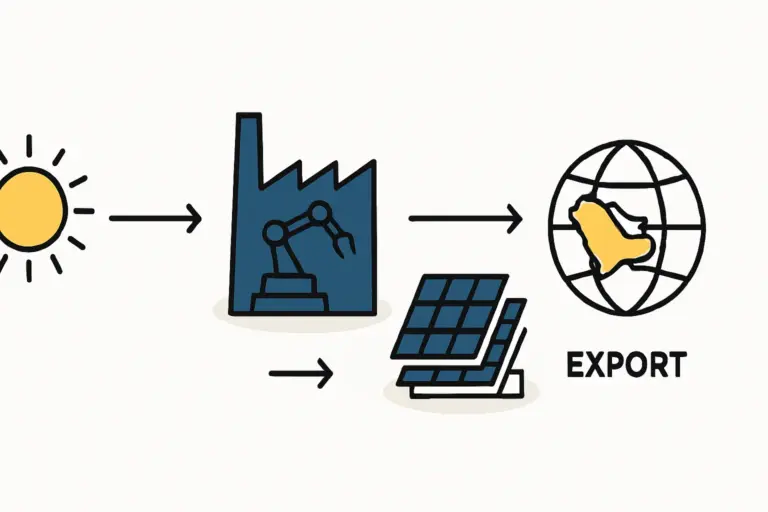

The Kingdom of Bahrain offers a unique combination of logistical, economic, and political factors that make it an ideal hub for advanced manufacturing. For an entrepreneur entering the solar industry, these factors mitigate risk and create a clear path to market.

Geographic and Economic Hub

Strategically located in the heart of the Gulf Cooperation Council (GCC), Bahrain offers unparalleled access to the region’s largest and fastest-growing solar markets, including Saudi Arabia and the UAE. Its world-class logistical infrastructure, supported by the Khalifa bin Salman Port and a causeway connection to Saudi Arabia, streamlines both the sourcing of raw materials and the distribution of finished goods.

National Commitment to Renewable Energy

Bahrain’s National Renewable Energy Action Plan (NREAP) and its Vision 2030 framework signal a strong government commitment to diversifying the energy mix. This creates stable, policy-driven local demand for solar components. The government’s goal to achieve 10% of its peak power capacity from renewables by 2035 translates into hundreds of megawatts of new solar projects, creating a foundational customer base for a local manufacturer.

A Mature Industrial Ecosystem

Bahrain is not new to heavy industry. The presence of world-class companies like Aluminium Bahrain (Alba) means a robust infrastructure, a skilled technical workforce, and a network of industrial suppliers are already in place.

This existing ecosystem significantly shortens the learning curve for a new manufacturing operation, from securing land in specialized industrial zones to recruiting qualified engineers and technicians. Support from the Economic Development Board (EDB) further streamlines the setup process for foreign investors, making it a supportive environment for new ventures.

The Technology Niche: Bifacial & DESERT+ Modules

Success in today’s solar market comes from specialization. For the GCC region, the optimal technology is not a standard solar panel, but one engineered specifically for its demanding desert environment.

Capturing More Energy with Bifacial Technology

Conventional solar modules only capture sunlight on their front side. Bifacial solar modules, however, feature a transparent backsheet or a second pane of glass, allowing them to also capture reflected light from the ground. In desert environments with light-colored sand, the ground’s high reflectivity (or ‘albedo’) can be substantial.

This design allows a bifacial module to generate up to 25% more energy than its monofacial counterpart under ideal conditions. For large-scale solar farm developers, this ‘bifacial gain’ translates directly into a higher return on investment, making these modules a preferred choice for utility projects across the Middle East.

Ensuring Durability with DESERT+ Certification

The desert environment is exceptionally harsh. Extreme daily temperature fluctuations, high UV radiation, humidity, and airborne sand can cause conventional solar modules to degrade prematurely—a significant risk for project financiers and operators.

To address this challenge, specialized testing standards have emerged. The ‘DESERT+’ certification, a stringent sequence of tests developed by institutions like the Fraunhofer Institute, validates a module’s ability to withstand these specific stressors. Modules meeting this standard utilize specialized materials:

- Reinforced Frames: To handle high wind loads.

- Specialized Encapsulants: To resist UV degradation and moisture ingress.

- Abrasion-Resistant Glass: With anti-soiling coatings to mitigate performance loss from dust accumulation.

By producing a module that is both bifacial and DESERT+ certified, a manufacturer can offer premium, bankable technology perfectly suited for the region’s primary market.

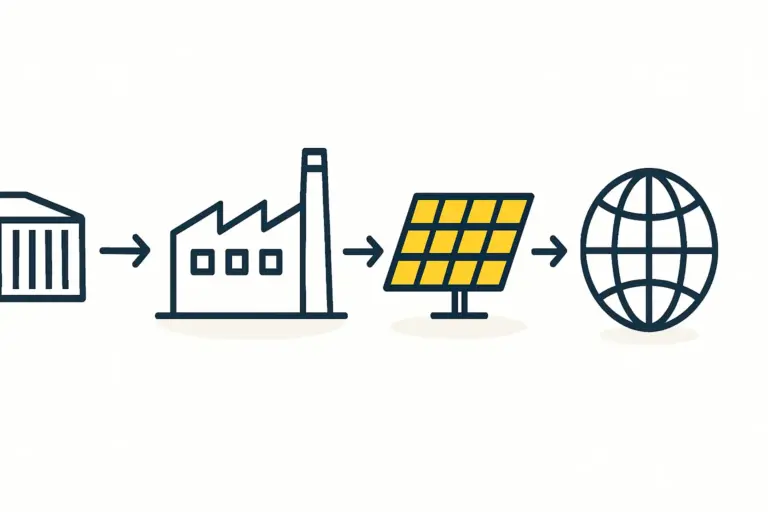

The Operational Blueprint: A Turnkey Approach

The vision of producing specialized modules must be backed by a robust operational plan. For entrepreneurs without a deep background in photovoltaic engineering, a turnkey factory solution is often the most efficient path to market.

This approach involves partnering with an experienced engineering firm that provides a complete production line—from machinery selection to process integration and staff training. Based on turnkey project benchmarks from European Solar PV equipment providers, establishing a 50–100 MW line for specialized modules typically requires a lead time of less than 12 months.

A typical turnkey line for producing bifacial and DESERT+ modules would include:

- High-Precision Stringers: Machines capable of handling advanced cell technologies like PERC or TOPCon, which are common in bifacial modules.

- Specialized Laminators: Configured to handle both glass-glass and glass-backsheet module structures, providing manufacturing flexibility.

- Class AAA Solar Simulators: Calibrated to accurately measure the performance of high-efficiency bifacial cells.

- Electroluminescence (EL) Testers: To ensure microcrack-free cells before and after lamination, a critical quality gate.

Partnering with a firm that has decades of experience, such EU PV factory turnkey supplier, ensures the equipment is not only state-of-the-art but also configured correctly to produce modules that can meet stringent certification requirements from the outset.

Financial Considerations and Market Outlook

Establishing a specialized factory is a significant undertaking, but the financial model is compelling. The initial investment for a 50–100 MW turnkey line typically falls within a predictable range, covering machinery, installation, training, and initial raw materials.

The key to profitability lies in the higher average selling price (ASP) and healthier margins that specialized modules command. While a standard module competes almost exclusively on price, a DESERT+ certified bifacial module competes on performance, reliability, and bankability—factors that utility-scale developers prioritize.

The target market extends far beyond Bahrain’s borders. The massive giga-projects in Saudi Arabia (e.g., NEOM) and the continued expansion of solar capacity in the UAE, Oman, and Kuwait represent a multi-billion-dollar annual market for high-performance modules. A Bahrain-based factory is perfectly positioned to serve this demand as a regional, high-quality supplier. A detailed financial projection is a core component of any professional business plan for such a factory.

Frequently Asked Questions (FAQ)

What is the primary advantage of bifacial modules in the GCC?

The primary advantage is higher energy yield. The sandy, light-colored terrain of the GCC region has a high albedo (reflectivity), meaning a significant amount of sunlight is reflected upwards. Bifacial modules capture this reflected light, increasing total energy production by 10–25% compared to monofacial modules in the same location.

Is deep technical expertise required to start such a factory?

While technical understanding is beneficial, it is not a prerequisite. Entrepreneurs with strong business acumen can succeed by partnering with an experienced turnkey provider. This allows the technical complexities of line design, machine commissioning, and process optimization to be managed by experts, freeing the business owner to focus on strategy, finance, and market development.

How long does it typically take to set up a production line?

For a semi-automated 50–100 MW line, the timeline from contract signing to the first certified module coming off the line is typically between 9 and 12 months. This includes factory layout planning, machine manufacturing, shipping, installation, and commissioning.

What kind of workforce is needed?

A 50 MW production line can be operated with approximately 25–30 employees per shift. This includes line operators, quality control technicians, maintenance engineers, and supervisory staff. Bahrain’s well-established industrial sector provides a strong talent pool for recruiting these roles.

From Strategic Insight to Actionable Planning

Launching a solar factory in Bahrain is not merely an industrial project; it is a strategic economic decision. By avoiding the commodity trap of standard modules and focusing on a specialized, high-demand technology, an entrepreneur can build a resilient and profitable business. The combination of a favorable location, targeted technologies like bifacial solar modules, and a proven operational blueprint offers a clear and compelling pathway to success in the GCC’s rapidly expanding renewable energy landscape.

View the full Bahrain Solar Module Manufacturing Case Study (PDF)

Author: This case study was prepared by the

turnkey solar module production specialists at J.V.G. Technology GmbH

It is based on real data and consulting experience from J.v.G. projects

worldwide, including installations ranging from 20 MW to 500 MW capacity.