While entrepreneurs planning a solar module factory in Bangladesh might focus on machinery, financing, and a skilled workforce, one of the most critical—and often underestimated—challenges lies in the country’s environmental laws.

Successfully navigating this regulatory landscape is key to a project’s long-term viability and profitability. For new investors, understanding the framework from the outset isn’t just a matter of compliance; it’s a strategic advantage.

This article offers a clear overview of the environmental regulations, agencies, and processes an investor must navigate when setting up a solar module production facility in Bangladesh. It’s designed to transform complex legal requirements into a practical roadmap for strategic business planning.

Table of Contents

The Regulatory Foundation: Key Authorities and Laws

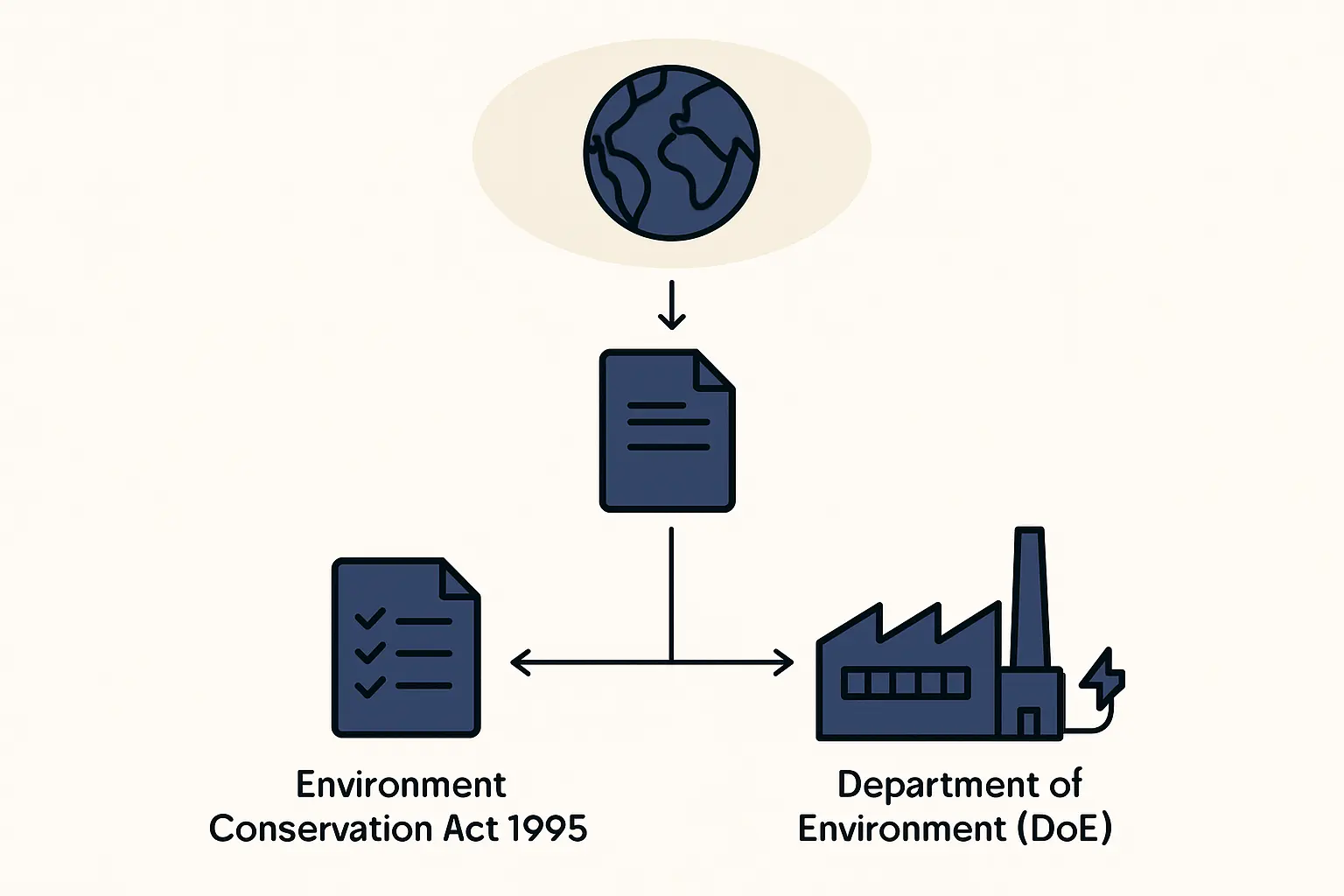

Any industrial facility in Bangladesh must adhere to a framework managed by key government bodies. For a solar module manufacturer, two organizations are paramount:

-

Department of Environment (DoE): As the principal enforcement agency, the DoE operates under the Ministry of Environment, Forest and Climate Change. It is responsible for implementing the country’s core environmental laws and issuing the necessary permits for industrial operations.

-

Sustainable and Renewable Energy Development Authority (SREDA): While SREDA’s main role is to promote renewable energy, it also collaborates with the DoE to ensure that green energy projects themselves are environmentally sound.

The DoE’s legal authority stems from two landmark pieces of legislation:

-

The Bangladesh Environment Conservation Act (BECA), 1995: This is the umbrella law for environmental protection, granting the DoE the power to create rules and standards to prevent pollution and conserve the environment.

-

The Environment Conservation Rules (ECR), 1997: These rules put BECA into practice. A critical component of the ECR is the classification of industries into four categories based on their potential environmental impact: Green, Orange-A, Orange-B, and ‘Red’.

A solar module manufacturing facility is classified as a ‘Red’ category industry because it uses chemicals, generates industrial byproducts, and has the potential for hazardous waste. This is the highest-risk category, requiring the most comprehensive level of environmental scrutiny before and during operation.

The Cornerstone of Compliance: The Environmental Clearance Certificate (ECC)

For any ‘Red’ category project, obtaining an Environmental Clearance Certificate (ECC) from the Department of Environment is the most critical regulatory step, as it’s illegal to begin construction or operation without it. The process is detailed and methodical, involving two main stages of assessment.

Step 1: The Initial Environmental Examination (IEE)

The IEE is a preliminary study submitted with the application for a Site Clearance Certificate. Its purpose is to:

- Identify potential environmental impacts of the proposed factory.

- Define the scope of a more detailed study.

- Provide an initial environmental management plan.

Based on the IEE, the DoE will grant a Site Clearance Certificate and issue specific Terms of Reference (ToR) for the next, more rigorous stage.

Step 2: The Environmental Impact Assessment (EIA)

The EIA is a comprehensive study conducted according to the ToR issued by the DoE. This in-depth analysis assesses the project’s potential effects on the local environment—including air, water, soil, and the surrounding community. A typical EIA for a solar factory will cover:

- Baseline Data: Detailed information about existing environmental conditions at the proposed site.

- Impact Prediction: Analysis of how the factory’s operations—from chemical handling to waste disposal—will affect baseline conditions.

- Mitigation Measures: A concrete plan detailing how the company will prevent, minimize, or manage negative impacts. This includes pollution control technology, waste management protocols, and emergency response procedures.

The DoE will issue the full Environmental Clearance Certificate (ECC) only after a satisfactory review of the EIA report. Based on experience from J.v.G. turnkey projects, entrepreneurs should budget between 6 and 12 months for the entire ECC process, as it involves detailed studies and regulatory reviews.

Core Compliance Areas for a Solar Module Factory

Beyond securing the initial ECC, a factory owner must manage ongoing compliance in several key areas. These are not just legal obligations; they are central to operational efficiency and corporate responsibility.

Managing Production Waste

The solar panel manufacturing process generates various waste materials, some of which are classified as hazardous under Bangladesh’s Hazardous Waste and Ship Breaking Waste Management Rules, 2011.

Key waste streams to manage include:

- Broken Solar Cells: Silicon wafers are fragile, and breakages are common. Silicon dust can be a respiratory irritant.

- Soldering Residues: The soldering process used to connect cells can leave behind residues containing lead and tin.

- Laminating Byproducts: Off-cuts of EVA (ethylene vinyl acetate) and backsheets are generated during lamination.

- Chemical Waste: Solvents and cleaning agents used in the facility require specialized handling and disposal.

A compliant factory must have dedicated, clearly marked areas for segregating and storing these wastes before they are collected by a DoE-authorized waste management company.

Air and Water Quality Standards

Airborne emissions and wastewater discharge are also strictly regulated.

-

Air Pollution: Fumes from soldering stations and the lamination process can release volatile organic compounds (VOCs). Proper ventilation and filtration systems are essential to meet DoE air quality standards.

-

Water Pollution: If water is used for cleaning glass or wafers, the resulting effluent must be treated to remove contaminants before discharge, ensuring it meets national standards for industrial discharge.

Future-Proofing: The Rise of E-Waste Regulations

While production waste is an immediate concern, an investor must also consider the end-of-life management of solar panels. Solar panels have a lifespan of 25-30 years, and as Bangladesh’s solar capacity grows, the volume of decommissioned panels will create a significant e-waste challenge.

The government is finalizing comprehensive E-waste Management Rules, which will classify end-of-life solar panels as electronic waste. These rules will likely introduce ‘Extended Producer Responsibility’ (EPR), requiring manufacturers to play a role in collecting and recycling their products. Planning for this eventuality now can create a significant competitive advantage in the future.

Solar Manufacturing“/>

Solar Manufacturing“/>Integrating Compliance into Your Business Plan

Rather than viewing these regulations as a burden, a prudent entrepreneur integrates them into the core business strategy from day one.

Site Selection and Factory Design

Environmental rules directly influence the choice of location and the physical design of the plant. An effective factory layout must incorporate:

- Designated and contained areas for hazardous waste storage.

- Sufficient space for water treatment plants or air filtration equipment.

- Logistics for the safe transportation of raw materials and waste.

A well-planned layout, designed with compliance in mind, prevents costly retrofitting later. A comprehensive turnkey solar factory solution often includes compliance-aware design as a core component, simplifying this process for investors new to the sector.

The Role of International Standards (ISO 14001)

While not legally mandatory in Bangladesh, voluntarily adopting an Environmental Management System (EMS) like ISO 14001 can be highly beneficial. It provides a systematic framework to manage environmental responsibilities, ensure continual improvement, and streamline the process of demonstrating compliance to the DoE. For export-oriented businesses, ISO 14001 certification is often a key requirement from international buyers.

Frequently Asked Questions (FAQ)

Q: What is the most critical first step for environmental compliance in Bangladesh?

A: The most critical step is to initiate the process for obtaining the Environmental Clearance Certificate (ECC) from the Department of Environment. No physical construction should begin before securing at least the initial Site Clearance Certificate.

Q: Can a foreign investor manage the EIA process alone?

A: While possible, it is highly recommended to engage a DoE-accredited local environmental consulting firm. These firms have the expertise to conduct IEE and EIA studies according to local requirements and can effectively liaise with the authorities—a common practice in successful project implementations.

Q: What are the penalties for non-compliance with environmental laws?

A: Penalties can be severe, ranging from financial fines to the shutdown of factory operations. Under the Environment Court Act, 2010, legal action, including imprisonment, can be taken against individuals responsible for causing significant environmental pollution.

Q: How does a ‘Red’ category classification impact the business financially?

A: A ‘Red’ classification requires a higher investment in environmental management. This includes the cost of the EIA study, the installation of pollution control equipment (e.g., water treatment plants), and ongoing expenses for waste management and environmental monitoring. These costs must be factored into the initial business plan.

Conclusion: Compliance as a Competitive Advantage

For the business professional entering Bangladesh’s growing solar market, environmental regulations are not a bureaucratic hurdle but an integral part of the business landscape. A proactive approach—understanding the laws, engaging expert help for the ECC process, and designing a factory with compliance built-in—is the most effective strategy.

By treating environmental management as a core business function rather than an afterthought, an investor not only ensures legal operation but also builds a resilient, responsible, and ultimately more profitable enterprise poised for long-term success.