Bangladesh has set ambitious goals for renewable energy, aiming for 40% of its electricity to come from clean sources by 2041. This national vision creates a significant opportunity for entrepreneurs looking to enter the solar module manufacturing market. Seizing it, however, requires a clear understanding of the country’s infrastructure, as a factory’s success hinges not just on its machinery but also on its connection to reliable power and efficient logistics.

For any investor or local business leader, a thorough assessment of the power grid and transportation networks is an essential first step. This article offers a realistic look at Bangladesh’s infrastructure landscape, outlining the primary challenges and strategic considerations for establishing a successful solar module production facility.

Table of Contents

The State of the National Power Grid: A Double-Edged Sword

In the high-precision environment of a modern solar module factory, automated machines like stringers and laminators need a constant, stable supply of electricity to operate properly. Any interruption or fluctuation can cause production stoppages, material waste, and potential damage to sensitive equipment.

Bangladesh has made impressive strides in expanding its power generation capacity, reaching an installed capacity of approximately 25,700 MW as of early 2023. On paper, this appears sufficient to meet national demand. However, the reality on the ground is more complex.

Key Challenges with the Grid:

-

Generation vs. Availability: A significant portion of the country’s power plants rely on imported natural gas and furnace oil. Global price volatility and supply chain disruptions can directly impact power generation, leading to fuel shortages and forced shutdowns.

-

Transmission & Distribution Losses: The grid infrastructure, while expanding, still suffers from technical losses and inefficiencies. This gap between generation and availability results in frequent load shedding, particularly outside major metropolitan areas.

-

Grid Instability: Frequent voltage fluctuations and power outages create an unreliable grid, posing a major business risk for any manufacturing operation—one that must be managed proactively.

For a prospective factory owner, relying solely on the national grid is not a viable strategy. The potential cost of lost production from just a single day of downtime can far outweigh the investment in a reliable backup power system—a reality that must be central to initial facility planning.

Planning for Energy Independence: Backup Power Strategies

Given the realities of the national grid, a robust backup power solution is not an option—it is a necessity. Entrepreneurs have two primary options for ensuring uninterrupted operations.

1. Diesel Generators

The conventional solution is to install diesel generators, which offer a lower initial capital investment and are a well-understood technology. However, this approach comes with significant long-term operational challenges:

-

Fuel Price Volatility: The cost of diesel is subject to market fluctuations, making it difficult to forecast operational expenses.

-

Logistical Hurdles: Securing a consistent supply of quality fuel can be a major logistical challenge.

-

Maintenance: Generators require regular maintenance, adding to the operational overhead.

2. Solar-Plus-Storage System

A more forward-looking strategy involves installing a dedicated solar PV system on the factory’s rooftop, coupled with a Battery Energy Storage System (BESS). While the initial investment is higher, the long-term benefits are substantial:

-

Energy Cost Control: A factory can generate a significant portion of its own clean energy, insulating it from grid electricity tariffs and fuel price hikes.

-

Operational Resilience: A correctly sized BESS can provide seamless power during grid outages, ensuring production continues without interruption.

-

Brand & Market Advantage: Manufacturing solar modules in a solar-powered facility is a compelling story that resonates with environmentally conscious buyers.

Based on experience from J.v.G. turnkey projects, incorporating a solar-plus-storage system from the outset is fast becoming the preferred model for new factories in regions with grid instability.

Logistics and Transport: Moving Materials and Finished Goods

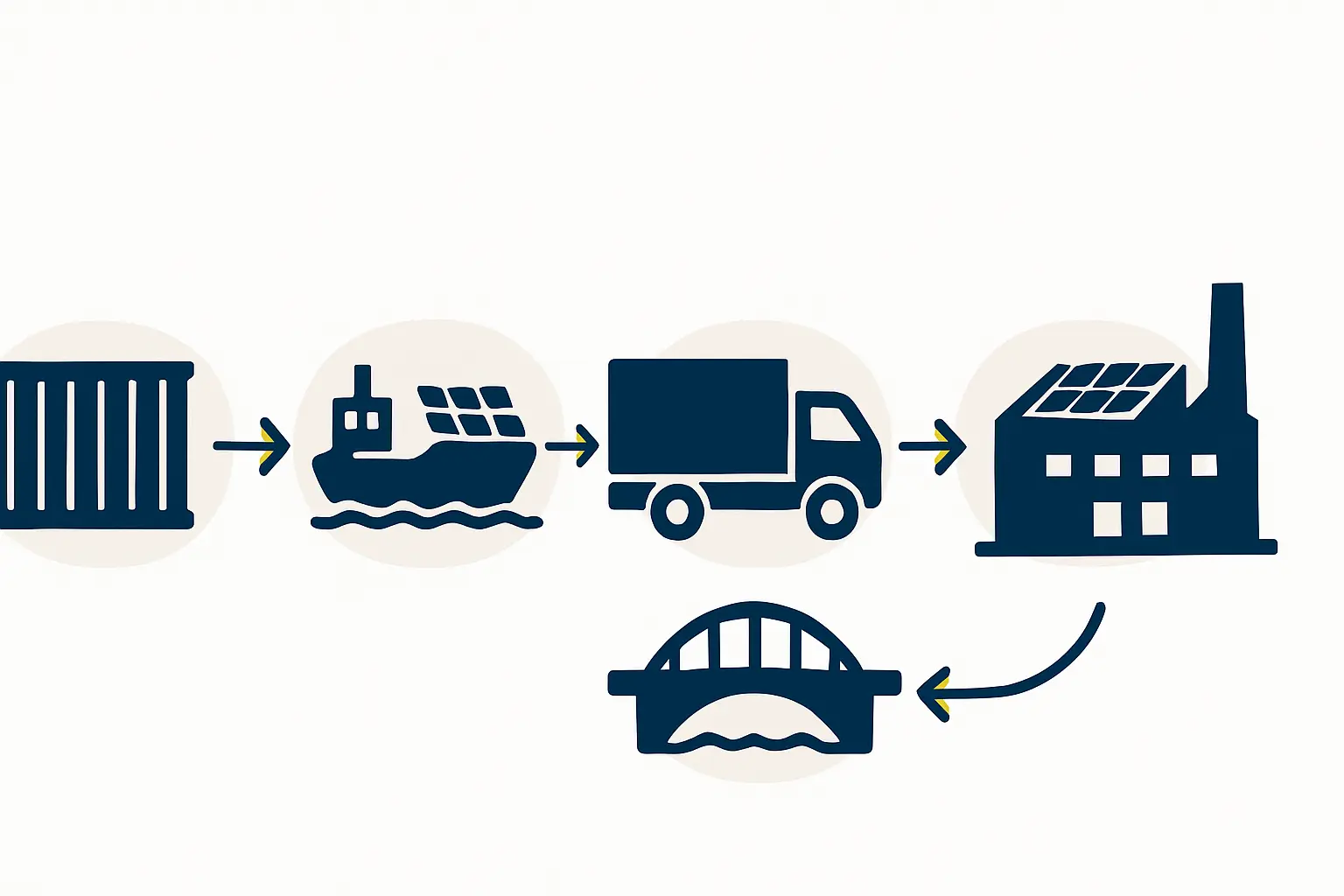

A solar module factory depends on a continuous flow of materials. Raw materials like solar cells, glass, and aluminum frames must be imported and transported to the factory, while finished modules must be distributed efficiently to project sites or shipped for export.

Port Infrastructure

Bangladesh’s primary gateway for seaborne trade is the Port of Chattogram (Chittagong), which handles over 90% of the country’s import-export activities. While it is the logistical heart of the nation, it frequently operates at or near full capacity, leading to potential delays in vessel berthing and cargo clearance. The Port of Mongla serves as a secondary option, though its inland connections are less developed.

Consequently, investors must factor potential port congestion into their supply chain planning and hold a sufficient buffer stock of critical raw materials—a key part of any bill of materials (BOM) strategy.

Inland Transportation

Once goods are cleared from the port, they must travel via road or rail. Bangladesh’s road network is extensive but faces its own challenges:

-

Traffic Congestion: Major arterial routes, especially the Dhaka-Chattogram highway, are prone to severe traffic congestion, significantly increasing transit times.

-

Road Conditions: While improving, some secondary roads may be unsuitable for heavy trucks carrying fragile materials like solar glass.

-

Seasonal Disruptions: The monsoon season can lead to flooding and road closures, creating unpredictable delays.

These logistical realities directly impact operational costs and production schedules, making strategic site selection critical to mitigating these risks.

Strategic Site Selection: Mitigating Infrastructure Risks

The ideal location for a solar module factory in Bangladesh balances land cost with access to critical infrastructure. Placing a factory in a remote area with cheap land but poor road access and an unstable grid connection is a recipe for failure.

Key considerations for site selection should include:

-

Proximity to a Power Substation: Being located near a reliable part of the electrical grid can reduce, but not eliminate, power quality issues.

-

Access to Major Highways: A location with direct access to a national highway connecting to a major port is essential for efficient logistics.

-

Availability of Labor: The site should be accessible to a pool of skilled and trainable workers.

-

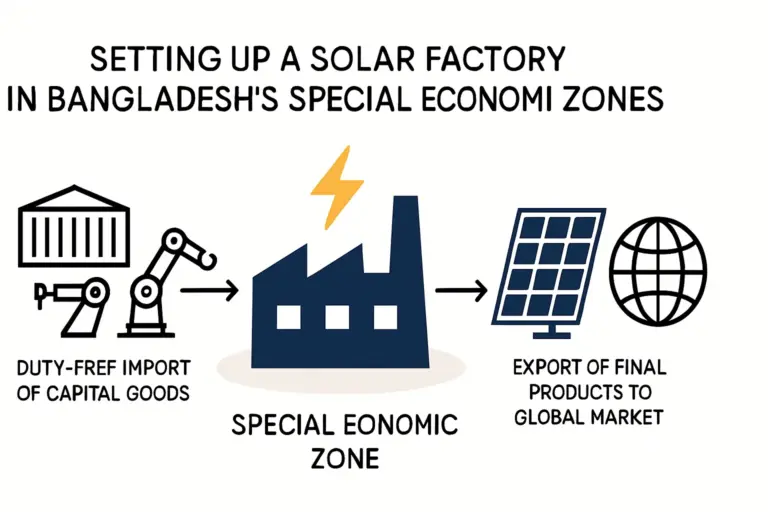

Economic Zones (EZs): The Bangladesh Economic Zones Authority (BEZA) is developing numerous EZs across the country. These designated zones often offer superior infrastructure—including more reliable power, pre-developed land, and streamlined administrative processes—making them highly attractive for new industrial projects.

FAQ: Common Questions on Bangladesh Infrastructure

Q: What is the single biggest infrastructure challenge for a new solar factory in Bangladesh?

A: The most critical challenge is the reliability of the national power grid. Frequent outages and voltage fluctuations demand a significant investment in a robust backup power system to ensure uninterrupted, high-quality production.

Q: Can a factory rely solely on the national grid?

A: It is highly inadvisable. The risk of production downtime, material waste, and equipment damage from grid instability is too high. A dedicated backup system, whether diesel or solar-plus-storage, is essential for operational viability.

Q: How do transport delays impact production costs?

A: Transport delays increase costs directly through higher freight charges and the need to hold more inventory, which ties up capital. They can also lead to production stoppages if raw materials run out and create the risk of penalties for late deliveries to customers.

Q: Are there specific regions in Bangladesh better suited for a factory?

A: Yes, regions with superior infrastructure are preferable. This includes areas within or near major government-sponsored Economic Zones, locations along the Dhaka-Chattogram industrial corridor, and sites with reliable access to the Port of Chattogram.

Conclusion: Planning for Success in a Promising Market

Bangladesh offers a compelling case for investment in solar module manufacturing, supported by strong government policy and growing domestic demand. However, the country’s infrastructure presents significant challenges that must be addressed with careful planning.

Success is not about ignoring these weaknesses but about strategically mitigating them. By investing in energy independence, selecting a site with strong logistical connections, and building a resilient supply chain, an entrepreneur can transform these obstacles into a competitive advantage.

For serious investors, the next step is to develop a detailed feasibility study and business plan that realistically accounts for these infrastructure-related costs and timelines. To get started on these critical early stages, explore the structured e-courses and resources available to guide you through your due diligence.