Even with a robust business plan for a new solar module factory, complete with funding and an identified market, success often hinges on something more fundamental than financial projections: the reliability of local infrastructure.

Before a single machine is installed, a critical question must be answered: Can the local power grid, water supply, and communication networks in Barbados support the demanding, 24/7 operations of a high-tech manufacturing facility?

This assessment provides a professional evaluation of essential utilities in Barbados for investors considering a solar module factory. It lays out a clear-eyed view of the opportunities and necessary risk mitigation strategies. Understanding this landscape is the first step toward building a resilient and profitable enterprise.

Table of Contents

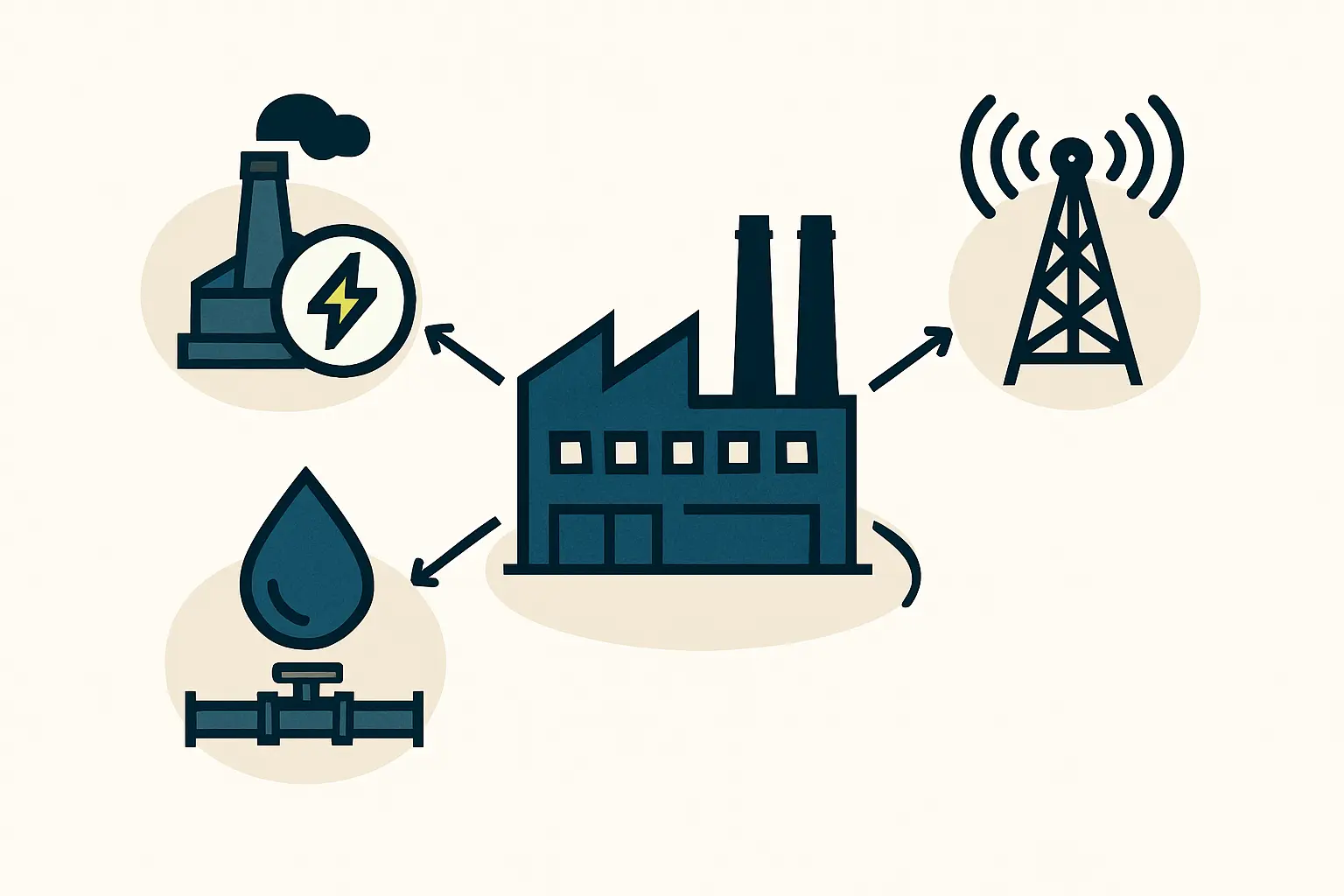

The Critical Role of Utilities in High-Tech Manufacturing

Modern solar module manufacturing is a precise and energy-intensive process. Unlike a simple warehouse or assembly plant, a solar factory’s machinery requires a stable, uninterrupted supply of high-quality power. Fluctuations or outages can damage sensitive equipment, ruin entire production batches, and lead to significant financial losses.

Beyond power, a consistent supply of clean water is essential for cooling systems and cleaning processes. Meanwhile, reliable, high-speed communication forms the backbone of logistics, supply chain management, and quality control.

A failure in any one of these three pillars—power, water, or data—can bring the entire operation to a halt. Thorough due diligence of this “invisible infrastructure” is not optional; it is a prerequisite for success. As investors evaluate the essential machinery for a solar module line, they must also assess the infrastructure required to run it.

Power Grid Stability and Capacity in Barbados

The foundation of any manufacturing operation is its power supply. In Barbados, the electricity sector is managed by the Barbados Light & Power Company (BLPC), which operates an installed generation capacity of 239.5 MW.

The country’s grid has historically relied heavily on imported fuel oil, but that is changing. The Government of Barbados has established an ambitious National Energy Policy (2019-2030) aiming to transition to 100% renewable energy sources and achieve carbon neutrality by 2030. This forward-thinking policy creates a favorable environment for solar-related investments.

Despite this positive outlook, investors must consider the practical realities. The existing grid, like many in the Caribbean, is centralized and can be vulnerable to disruptions from severe weather events like hurricanes. For a manufacturing facility requiring constant power, relying solely on the grid presents an unacceptable business risk.

Mitigation Strategy:

Based on experience from J.v.G. turnkey projects in various markets, a robust backup power system is a non-negotiable part of the facility plan. This typically includes:

-

Diesel Generator: Sized to power all critical production machinery and facility operations during a grid outage.

-

Uninterruptible Power Supply (UPS): For sensitive electronic equipment like servers and control systems to ensure a seamless transition to generator power without data loss or damage.

These systems are essential for operational continuity and must be factored into the initial investment requirements.

Water Supply: Availability and Quality

The Barbados Water Authority (BWA) manages the island’s water resources. The water is sourced primarily from groundwater stored in the island’s natural coral limestone aquifers and is generally of high quality, requiring minimal treatment.

However, the BWA faces challenges with an aging distribution network. This can lead to intermittent service interruptions and periods of low water pressure, particularly in areas at higher elevations. While these outages may be a minor inconvenience for residents, they represent a critical failure point for a manufacturing process.

Mitigation Strategy:

To insulate a factory from inconsistencies in the municipal supply, on-site water storage is a standard and effective solution. A system of storage tanks, sized to hold at least a 24- to 48-hour supply of operational water, provides a crucial buffer. This ensures that production can continue uninterrupted during short-term BWA service disruptions, protecting valuable work-in-progress.

Communications and Data Infrastructure

In today’s manufacturing environment, data is as vital as electricity. Barbados boasts a modern and relatively robust communications infrastructure. The market is served by two main providers, Flow (Cable & Wireless) and Digicel, both of which have invested heavily in fiber-optic networks. The widespread availability of “Fibre to the Home” (FTTH) means that high-speed, reliable internet is accessible across most of the island.

This level of connectivity is a significant advantage, enabling seamless implementation of:

- Enterprise Resource Planning (ERP) systems for managing inventory and production.

- Real-time communication with global suppliers and customers.

- Remote diagnostics and support from equipment manufacturers or consultancy partners like J.v.G. Technology.

Solar Manufacturing in Belarus”/>

Solar Manufacturing in Belarus”/>Mitigation Strategy:

While the core network is strong, absolute dependability is paramount. To achieve near-100% uptime, the prudent strategy is to establish redundancy. This typically means contracting with two different service providers or complementing a primary fiber line with a satellite or high-speed wireless backup connection. This small additional investment provides critical insurance against rare but potentially costly internet outages.

A Holistic View for Site Selection

Power, water, and communication systems are interconnected. A major power outage, for example, will likely impact water pumping stations and telecommunication towers. When choosing the right location for a solar factory, assessing these utilities not in isolation but as an interdependent system is vital.

A thorough site survey should include direct consultations with BLPC and BWA to understand the specific capabilities and potential weaknesses of the Barbados infrastructure serving a proposed location. Proper diligence ensures the chosen site can support the facility’s needs from day one, with a comprehensive resilience plan integrated into the factory’s design and budget.

Frequently Asked Questions (FAQ)

How much backup power is needed for a typical solar factory?

The required capacity depends on the factory’s scale. For a 20-50 MW annual production line, a diesel generator in the range of 500-750 kVA is a common starting point. However, a detailed electrical load analysis must be conducted by engineers to determine the precise size needed to power all critical machinery and support systems.

Can a solar factory be powered by its own solar panels?

While a factory can and should install a significant solar PV system on its rooftop to offset energy costs and align with its business model, this system cannot serve as the primary power source. The energy-intensive machinery requires a constant, high-amperage power draw that is best supplied by a stable grid connection, backed up by a generator. The factory’s own PV system helps reduce operational expenses but does not replace the need for reliable grid power.

Are these infrastructure challenges unique to Barbados?

No. Assessing utility reliability and planning for redundancy are standard components of due diligence for any industrial project in nearly any country, including in highly developed economies. These considerations are a normal part of the structured planning process that platforms like pvknowhow.com guide new investors through. The specific risks vary by location, but the methodology for identifying and mitigating them is universal.

What is the first step in assessing a potential site’s infrastructure?

The first step is to move beyond publicly available information and engage in direct consultation. This means formally contacting the local utility providers (power and water) with the projected consumption figures for the proposed factory. This initial contact should be followed by a physical site inspection and, ideally, engaging a local engineering consultant to conduct a formal infrastructure audit.