An entrepreneur planning to establish a solar module factory understandably focuses on the core elements: securing machinery, designing the production layout, and sourcing raw materials.

Imagine selecting a prime location in Belgium, a logistical hub at the heart of Europe. The building is scoped out, the business plan is solid. Yet an often-underestimated hurdle emerges—not from technology or finance, but from a complex web of regional environmental regulations.

This is a common scenario. For many investors, particularly those from outside the European Union, the intricacies of environmental compliance pose a significant challenge, with Belgium’s unique federal structure presenting a special case.

Understanding this landscape isn’t merely a bureaucratic step; it’s fundamental to a project’s timeline, budget, and ultimate success. This article provides a clear, business-focused overview of the environmental permit system for solar module manufacturing in Belgium.

Table of Contents

The Cornerstone of Compliance: The Single Environmental Permit

Unlike jurisdictions that require separate permits for construction, operation, and environmental impact, Belgium streamlines this process for industrial projects through a single, integrated environmental permit. In Flanders, this is the omgevingsvergunning; in Wallonia, the permis d’environnement.

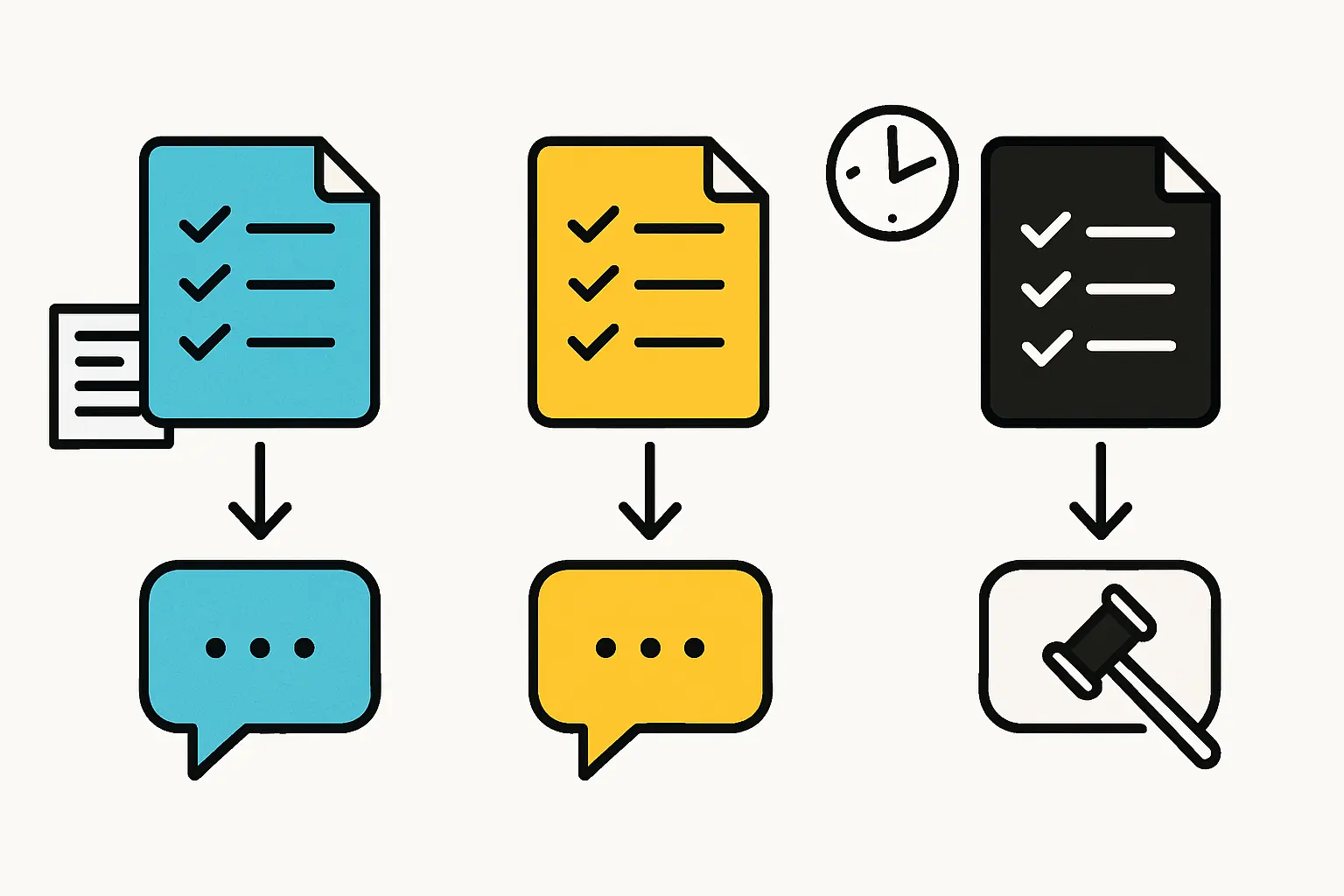

The permit’s specific requirements, however, depend on the facility’s potential impact, which is categorized into three classes:

Class 1:

For activities with the highest potential environmental impact. These require a full Environmental Impact Assessment (EIA) and involve a comprehensive public inquiry.

Class 2:

For activities with a moderate impact. These require a simplified application process and a more limited public review.

Class 3:

For activities with a low impact, typically requiring only a formal notification to the authorities.

A new solar module manufacturing plant, even a modest one with 50-100 MW annual capacity, will almost certainly fall into Class 1 or Class 2.

This classification is driven by factors inherent to production, such as chemical usage, water discharge, air emissions, and waste generation. A prospective owner must therefore plan for a thorough application and review procedure.

A Tale of Three Regions: Why Location Within Belgium Matters

In Belgium, environmental law is a regional competence. This makes the facility’s location the single most important factor in determining the specific rules for your permit. The regulations in Flanders differ from those in Wallonia and the Brussels-Capital Region.

Flanders

In the northern, Dutch-speaking region of Flanders, the process is governed by the Flemish Regulation concerning Environmental Permits (VLAREM). All applications are managed through a centralized digital portal, the Omgevingsloket, which is designed to streamline the process for both applicants and regulators.

Wallonia

In the southern, French-speaking region of Wallonia, the permis d’environnement is regulated by the Walloon Code of the Environment. While the principles, including the classification system, are similar to those in Flanders, the specific administrative procedures, technical standards, and competent authorities are distinct.

Brussels-Capital Region

The Brussels-Capital Region operates under its own environmental legislation. Given its urban density and focus on service industries, it is a less common location for new, large-scale manufacturing facilities, but it remains a third, independent regulatory jurisdiction.

This regional division means a one-size-fits-all approach to permitting in Belgium is impossible. Your choice of site directly dictates the legal framework, the application language (Dutch or French), and the specific government agencies you will work with.

Key Environmental Considerations for a Solar Module Factory

A permit application must provide a detailed account of how the factory will manage its environmental footprint. For solar module production, several areas require particular attention.

Waste Management

Production generates a significant volume of industrial waste, including broken solar cells, trimmings from encapsulant (EVA) and backsheet materials, and packaging. The facility’s plan must detail how these materials will be sorted, stored, and sent to licensed recycling or disposal companies. Furthermore, under the EU’s Waste from Electrical and Electronic Equipment (WEEE) Directive, the factory is considered a producer and thus becomes responsible for the end-of-life management of its modules. This requires detailed waste management planning from day one.

Chemical Handling and Storage

The solar module manufacturing process uses various chemicals—including soldering fluxes, cleaning solvents, and sealant primers—that must be managed in compliance with the EU’s REACH regulation. The permit application must detail plans for secure chemical storage areas with spill containment, as well as procedures for safe handling and disposal.

Air and Water Discharges

Air Emissions:

The lamination process, where the solar cell sandwich is heated, can release Volatile Organic Compounds (VOCs) from the encapsulant materials. The factory design must include ventilation and potentially air treatment systems, like scrubbers, to keep emissions below legal thresholds.

Water Discharge:

Water used for washing solar glass before assembly contains contaminants. This process water cannot be discharged directly into the municipal sewer system without prior analysis and, typically, on-site treatment to meet local water authority standards.

The Permitting Process: A Practical Timeline

While timelines vary with project complexity and region, a typical path for a Class 1 or 2 facility follows these steps:

- Pre-Application Consultation: Engaging with municipal and regional authorities before submitting a formal application is highly advisable to identify potential issues early.

- Dossier Preparation: This is the most intensive phase, involving the compilation of technical drawings, operational descriptions, environmental impact studies, and mitigation plans.

- Submission and Review: Once submitted, the application undergoes a formal review for completeness. This is followed by a public inquiry period, where local residents and organizations can review the plans and voice comments or objections.

- Decision and Appeal: The competent authority issues a decision within a legally defined period. This decision can then be appealed by the applicant or third parties.

Business-Relevant Metric: Entrepreneurs should factor 9 to 18 months into their project timeline for the entire environmental permitting process—from dossier preparation to receiving a final, non-appealable permit. This process is not an administrative afterthought; it is a critical-path item that runs parallel to financing and equipment procurement.

Frequently Asked Questions (FAQ)

Q: Do I need a local consultant for the permit application?

A: While not legally required, engaging a specialized Belgian environmental consultant is strongly recommended. They have in-depth knowledge of regional regulations, established relationships with authorities, and can prepare the complex dossier in the required local language (Dutch or French).

Q: How does the EU’s WEEE directive affect my factory directly?

A: As a manufacturer, you are classified as a producer. This means you must register with a regional WEEE compliance body (e.g., Recupel in Belgium) and pay an annual fee that contributes to the national system for collecting and recycling solar modules at the end of their life. This ongoing operational cost must be built into your financial projections.

Q: What is an EIA and will my factory need one?

A: An Environmental Impact Assessment (EIA) is a comprehensive study of a project’s potentially significant environmental effects. For a Class 1 facility—a likely classification for a new, medium-to-large solar factory—a full EIA is mandatory. This detailed, public document is a core part of the permit application.

Q: Can J.v.G. Technology assist with the environmental permit process?

A: J.v.G. Technology GmbH specializes in the technical planning, engineering, and commissioning of solar module production lines. Drawing on experience from numerous turnkey projects, our team understands precisely how facility design, machine selection, and process flows impact environmental compliance. We can provide the essential technical data for your permit dossier and collaborate effectively with your chosen local environmental consultants to ensure the plans are both operationally efficient and legally compliant.

Conclusion: Compliance as a Strategic Advantage

Navigating Belgium’s environmental permit system requires diligence, foresight, and specialized knowledge. For any investor, the key is to recognize the importance of the country’s regional structure, plan for a comprehensive single permit application, and allocate sufficient time and resources for the process.

Viewing this process not as a bureaucratic obstacle but as a framework for building a high-quality, sustainable, and responsible enterprise is a strategic advantage. A properly permitted facility demonstrates long-term commitment and builds trust with regulators, the financial community, and local stakeholders. For those looking to build a resilient business in the European solar market, mastering compliance is the first step.

To understand the broader context, a complete guide on how to start a solar module factory offers a structured overview of the entire journey.