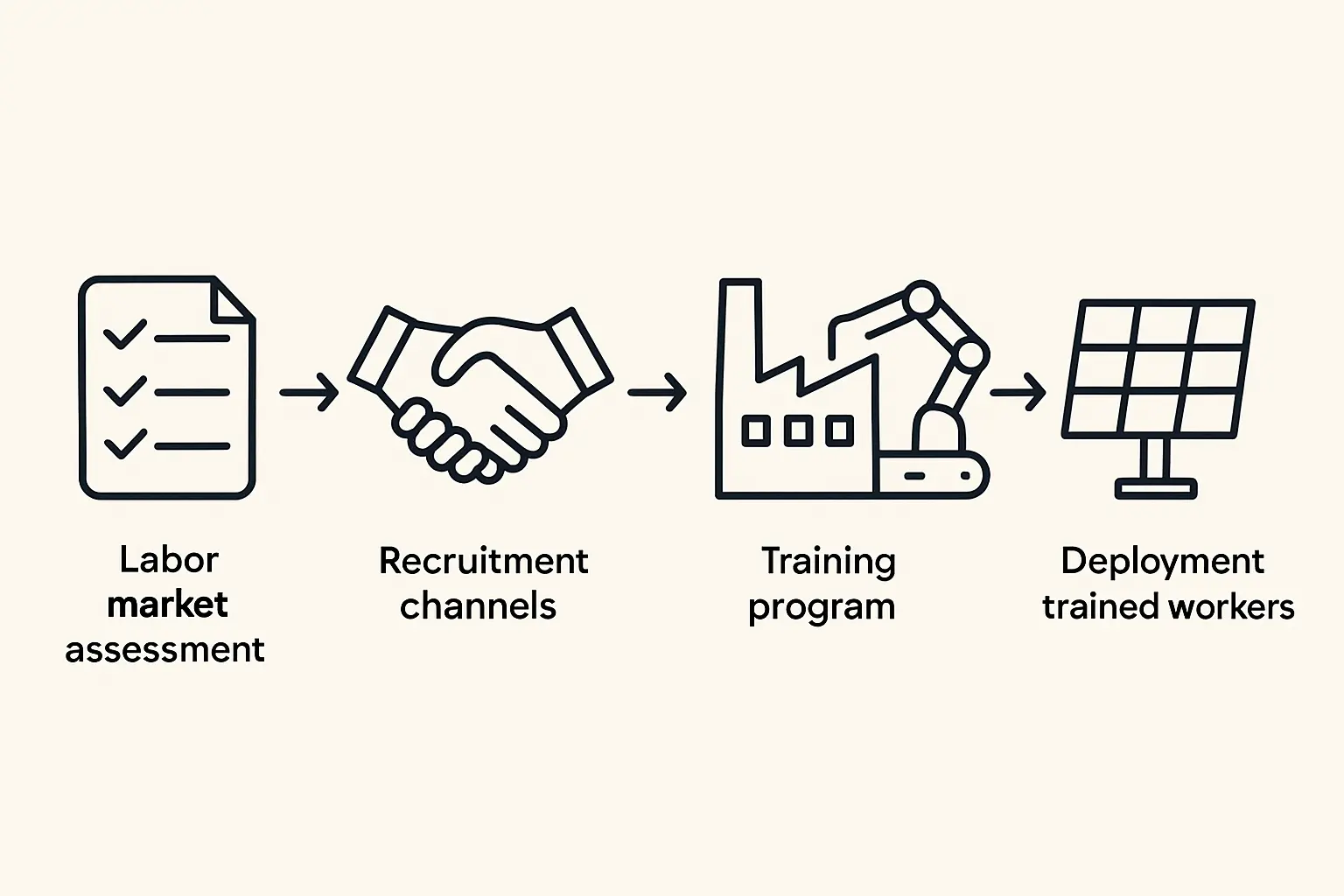

While machinery, financing, and location are essential for starting a business, the most critical asset in solar module manufacturing isn’t the equipment—it’s the people who operate it. Benin, with a median age of just 17.5 years, has an immense potential workforce. Tapping into this demographic dividend requires a strategic approach to **recruitment and training**—two core components of managing labor and supply chains.

Successfully launching a solar factory in Benin is less about finding existing experts and more about creating them. The real work lies in transforming motivated individuals with general aptitude into skilled technicians who can confidently run a modern production line.

Table of Contents

Understanding Benin’s Labor Landscape: Potential and Prerequisites

For industrial investors, Benin presents a unique mix of opportunity and challenge. Understanding this context is the first step in developing a realistic workforce strategy.

The Demographic Advantage:

With over half its population under 18, Benin has an abundant and energetic pool of potential employees. These young workers are often eager for stable, long-term employment and receptive to new skills—a stark contrast to many developed nations facing aging populations and labor shortages.

Educational and Skill Levels:

While enthusiasm is high, a realistic assessment of the local skill base is critical. With a national literacy rate of approximately 45.4%, training programs cannot assume a high level of formal academic knowledge. Instead, they must prioritize hands-on, visual, and repetitive learning methods.

The official language is French, which is essential for management, documentation, and formal procedures. However, many potential candidates will primarily speak local languages like Fon or Yoruba, so bridging this communication gap requires bilingual supervisors or materials.

Strategic Recruitment Channels in Benin

Identifying the right candidates requires moving beyond conventional job portals and embracing a localized approach.

-

Collaboration with Technical and Vocational Schools

Institutions like the Lycée Technique de Kpondéhou in Cotonou and other regional vocational training centers are primary sources of talent. Although their graduates may not have solar-specific knowledge, they possess a foundational understanding of technical principles, safety protocols, and workshop discipline. Building relationships with these schools can create a dependable pipeline of promising candidates. -

Leveraging Government Employment Agencies

The Benin government, through its Programme d’Action du Gouvernement (PAG), is actively promoting industrial employment, making the national employment agency, Agence Nationale Pour l’Emploi (ANPE), a valuable partner. The agency can assist with pre-screening candidates based on defined criteria, organizing recruitment drives, and navigating administrative employment requirements. -

Community-Based Recruitment

In a culture that values community ties, engaging directly with local leaders is highly effective. Announcing opportunities through trusted community heads builds goodwill and attracts candidates vetted by their own communities. Experience from J.v.G. projects in similar markets shows this approach often yields loyal and motivated employees.

Designing an Effective Training Program for Solar Module Assembly

The foundation of any successful solar factory in Benin is the quality of its training program. The most effective strategy is a phased approach that systematically builds skills from the ground up.

Phase 1: Foundational Industrial Skills

The first stage focuses on basics that are transferable across any industrial setting. This is crucial for employees who may have no prior factory experience.

- Workshop Safety: Proper handling of materials, use of personal protective equipment (PPE), and emergency procedures.

- Quality Consciousness: An introduction to the concept of “right first time,” the cost of defects, and the importance of precision.

- Basic Metrology: Using simple measurement tools like calipers and rulers with accuracy and consistency.

- Teamwork and Communication: Establishing clear protocols for communicating on the production line.

Phase 2: Machine-Specific Operational Training

Once foundational skills are in place, training moves to the specific equipment on the production line, emphasizing a practical, hands-on approach. For an investor implementing a Turnkey Solar Production Line, the equipment supplier often provides initial training for a core team. This core team, typically led by an experienced expatriate technician, then trains the rest of the operators. Key machines include:

- Stringer: The machine that solders solar cells together into strings.

- Layup Station: Where the different layers of the module are assembled.

- Laminator: The machine that uses heat and pressure to encapsulate the solar cells.

- Framer and Junction Box Station: The final assembly steps.

Phase 3: Advanced Skills and Career Progression

Developing a second layer of skilled personnel is vital for long-term operational stability. This phase focuses on identifying high-potential operators for advanced training in:

- Quality Control (QC): Training inspectors to use electroluminescence (EL) and sun simulator testers to identify and classify module defects.

- Maintenance: Developing a local team of technicians who can perform routine maintenance and basic troubleshooting, reducing reliance on external support.

- Line Supervision: Promoting from within to create line leaders who understand both the technical process and team dynamics.

Integrating Workforce Strategy into Your Financial Planning

New investors often underestimate the investment required for workforce development, a critical part of a comprehensive Business Plan for Solar Production.

A semi-automated 25-50 MW production facility typically requires a workforce of 30 to 50 employees, including production operators, quality inspectors, maintenance staff, warehouse personnel, and administrators. The budget should account not only for salaries but also for the initial three- to six-month period of intensive training when productivity will be low. This investment in human capital ultimately guarantees the factory’s long-term quality and efficiency.

Frequently Asked Questions (FAQ)

What level of education is realistic for entry-level operators?

A primary or lower secondary education is often sufficient for entry-level operator roles, provided the training program is practical, hands-on, and does not rely heavily on written manuals. The key attributes are motivation, good dexterity, and a willingness to learn.

How important is the French language for management?

French is essential for the plant manager, key supervisors, and administrative staff. It is the language of business, regulation, and communication with government entities. However, line supervisors should ideally be bilingual in French and a major local language to effectively manage and train operators.

What are typical labor costs in Benin for this sector?

Labor costs in Benin are significantly lower than in Europe, North America, or Asia. While this provides a competitive advantage, offering fair wages that are competitive in the local market is crucial for attracting and retaining the best talent. Specific figures should be researched as part of detailed business planning.

How long does it take to train a new team to operate a production line?

Based on J.v.G. Technology GmbH’s experience with turnkey projects, a new team can typically be trained to operate a line at a basic level of proficiency within three to six months. Achieving high levels of efficiency and quality consistency may take up to a year as the team gains experience and internal expertise develops.

Conclusion: Your Next Steps in Workforce Development

The success of a solar manufacturing venture in Benin is fundamentally tied to its people. The country’s young and motivated population is a powerful asset for any entrepreneur willing to invest in structured, practical training. By building a skilled workforce from the ground up, a company not only ensures its own operational success but also contributes significantly to the local economy.