For entrepreneurs monitoring Bolivia’s expanding energy landscape, the massive solar projects driven by the Empresa Nacional de Electricidad (ENDE) represent a significant opportunity.

Looking at these vast arrays of photovoltaic panels, you might ask, “How can my new manufacturing facility become a key supplier for these pivotal national projects?” This isn’t just a question of sales; it’s about strategic alignment, technical excellence, and navigating a complex state-level partnership.

Supplying a state-owned utility like ENDE requires more than a quality product. It demands a deep understanding of the national energy strategy, procurement processes, and technical requirements—all of which differ markedly from the private sector. This guide provides a strategic framework for new solar manufacturers aiming to partner with Bolivia’s primary electricity provider.

Table of Contents

Understanding ENDE’s Role in Bolivia’s Energy Future

The Empresa Nacional de Electricidad (ENDE) is central to Bolivia’s energy sector. As the state-owned entity responsible for generating, transmitting, and distributing electricity, it also serves as the primary instrument for executing the government’s long-term energy policy. These policies are often outlined in national development plans like the “Plan de Desarrollo Económico y Social” (PDES).

Under these frameworks, ENDE has been tasked with diversifying Bolivia’s energy matrix away from its heavy reliance on natural gas. This mandate has driven the development of major renewable energy projects with a strong focus on solar power, particularly in the high-irradiation regions of the Altiplano. Projects like the Oruro and Uyuni Solar Plants are flagship examples, often involving hundreds of megawatts in capacity.

For a new solar module manufacturer, understanding this context is critical. ENDE is not merely a customer but a strategic partner in achieving national objectives. This means procurement decisions are influenced by factors beyond price, including:

- Alignment with National Goals: How a supplier contributes to energy independence and technological sovereignty.

- Long-Term Reliability: The ability to provide consistent quality and support for projects with a 25+ year lifespan.

- Technical Suitability: Ensuring modules can perform optimally in Bolivia’s unique environmental conditions, such as high altitude and intense UV radiation.

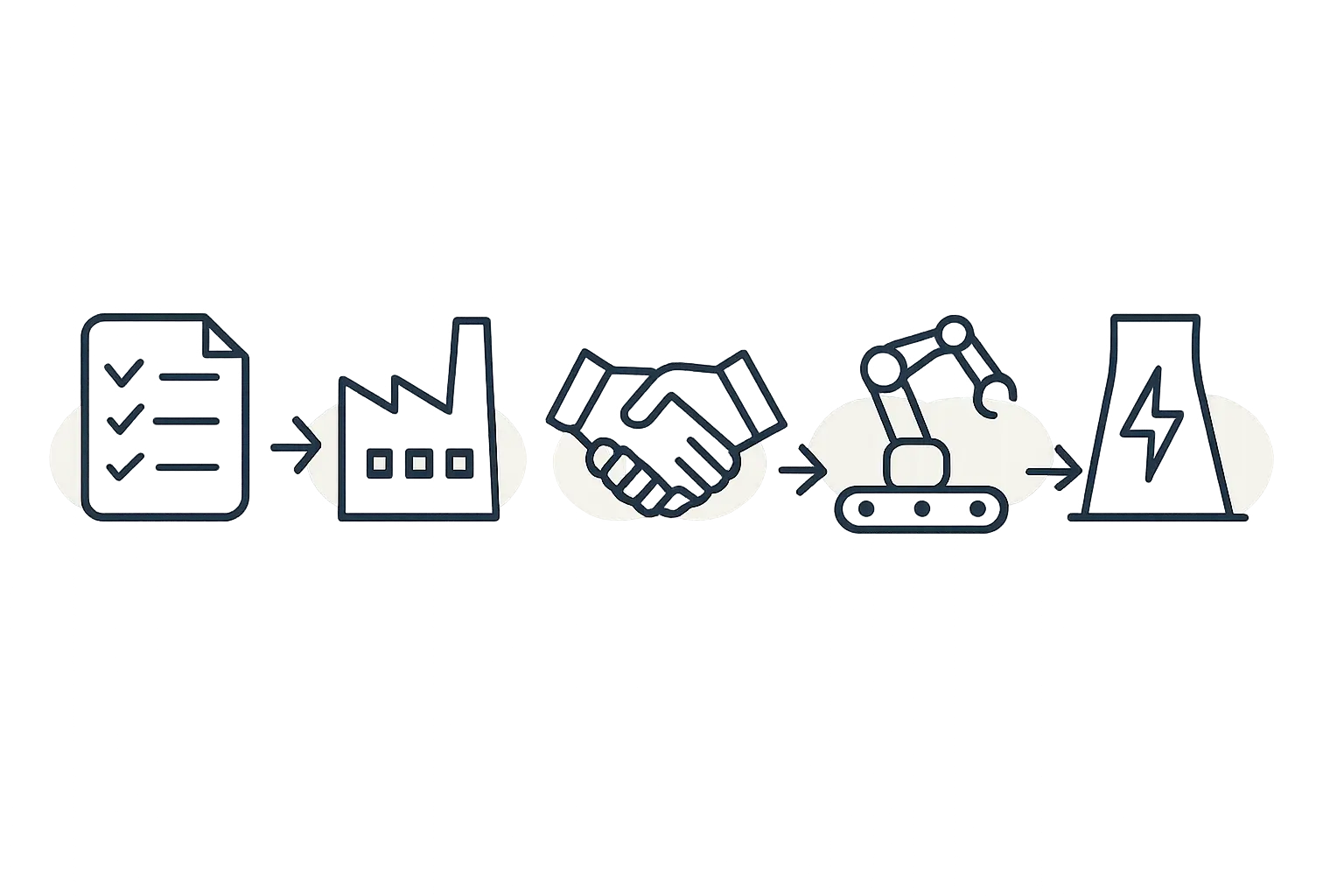

The Pathway to Becoming a Qualified Supplier

Engaging with ENDE is a formal, structured process, fundamentally different from securing private-sector contracts. The journey from prospective supplier to trusted partner requires meticulous preparation to navigate a series of regulatory, technical, and financial hurdles.

Navigating the Tendering and Procurement Process

Most of ENDE’s large-scale procurement is conducted through formally announced public tenders (licitaciones públicas), which require interested parties to follow a strict set of procedures. A crucial first step for any prospective supplier is registering with Bolivia’s national registry for state suppliers, ensuring the company is recognized as a legitimate entity eligible for government contracts.

The tender documents themselves are typically extensive, demanding detailed information on corporate structure, financial health, and technical capabilities. Experience with similar state-led projects shows that incomplete or improperly formatted submissions are a primary reason for disqualification.

Key Technical and Quality Requirements

While price is a factor, technical compliance is non-negotiable. ENDE’s engineering standards for large utility-scale projects are rigorous, and any new manufacturer must demonstrate that its products meet or exceed international benchmarks. A critical component of this is obtaining the necessary IEC certifications—such as IEC 61215 and IEC 61730—which validate module performance, safety, and reliability.

Beyond standard certifications, ENDE may specify additional requirements tailored to local conditions:

- High-Altitude Performance Data: Evidence of low power degradation at altitudes exceeding 3,000 meters.

- PID Resistance: Strong resistance to Potential Induced Degradation, a key concern in large, high-voltage systems.

- Local Content: While not always mandatory, preference may be given to suppliers who can demonstrate a degree of local value creation, whether through assembly, local sourcing of materials, or partnerships with Bolivian firms.

Financial and Operational Due Diligence

To be considered for a multi-megawatt project, a supplier must prove its operational and financial stability. ENDE needs assurance that a manufacturer can handle a large order without compromising on quality or delivery schedules. This requires transparent documentation of the factory’s production capacity, quality control processes, and balance sheet.

For entrepreneurs in the planning stage, accurately calculating solar factory investment costs and securing adequate funding is a foundational step, long before approaching a state utility.

Common Challenges and Strategic Considerations

The path to becoming an ENDE supplier is rewarding but comes with distinct challenges. Acknowledging these realities is key to developing a resilient strategy.

Bureaucratic Delays and Political Influence

As with many state-owned enterprises globally, processes can be slowed by bureaucracy. The timeline from tender submission to contract award can be lengthy, and shifts in government policy or administration can impact project priorities. Successful partners demonstrate patience, maintain professional communication, and build relationships based on technical competence and trust.

Payment Terms and Financial Planning

Payment schedules for government contracts can be longer and more complex than in the private sector. They are often tied to specific project milestones and require extensive documentation. This necessitates robust cash flow management and financial planning to ensure a manufacturer’s operations are not constrained while awaiting payment.

The Importance of a Local Partner

For an international entrepreneur, partnering with a reputable Bolivian company can be a significant strategic advantage. A local partner can provide invaluable help navigating the regulatory environment, understanding cultural business practices, and building relationships with key stakeholders. They can also assist with logistics and on-the-ground support—both critical for smooth project execution.

A Case Study Perspective: Lessons from Past Projects

Valuable lessons can be learned from the experiences of others. For instance, an international consortium bidding to supply a major solar project in the region learned a hard lesson when its bid was rejected not for price or core technology, but for failing to provide third-party validation of its module’s performance under the high-UV and low-temperature conditions of the Altiplano. This case highlights a critical point: generic technical data is simply not enough. A successful bid requires documentation that speaks directly to the unique challenges of the project’s specific location.

Frequently Asked Questions (FAQ) for Aspiring ENDE Partners

Q: Does ENDE prioritize local manufacturers over international ones?

A: ENDE’s primary goal is to secure reliable, high-performance technology for its national projects. While there may be a preference for local content to stimulate the national economy, international quality standards and financial stability remain paramount. A new local manufacturer must prove it can compete on a technical level with established global players.

Q: What is the typical size of a solar module order from ENDE?

A: Orders for utility-scale projects are substantial, often ranging from 20 MW to over 100 MW for a single project phase. This requires a manufacturer to have certified production capacity to meet these volumes.

Q: How long does the supplier approval process typically take?

A: The process can vary significantly depending on the project. From the announcement of a public tender to the final selection of a supplier, it can take anywhere from six months to over a year.

Q: Do I need a physical presence in Bolivia to become a supplier?

A: While not always a strict requirement to submit a bid, having a legal representative or a strong local partner in Bolivia is highly advantageous for navigating the process and is often essential for contract execution and post-sales support.

Q: What are the most critical certifications ENDE looks for?

A: The baseline is always IEC 61215 for performance and IEC 61730 for safety. Depending on the project, additional certifications related to ammonia resistance, salt mist corrosion, or PID resistance might be specified.

Next Steps: Preparing Your Manufacturing Operation for Success

Becoming a strategic supplier to a national utility like ENDE is a marathon, not a sprint. It requires a long-term vision built on technical excellence and procedural discipline.

The first step is not to draft a proposal, but to ensure the manufacturing operation itself is sound. This means developing a comprehensive business plan, designing a factory capable of producing certified, high-quality modules, and understanding the entire value chain.

Before engaging in complex state-level procurement, having a clear operational roadmap is essential. Laying this groundwork requires a fundamental understanding of how to start a solar module factory. A structured approach, guided by experienced consultants, can help new entrants build a manufacturing operation credible enough to win the trust of a major player like ENDE.