To many international observers, Bolivia is a nation rich in natural resources, yet a significant portion of its population lives without electricity—a basic modern utility. While its cities are brightly lit, vast rural territories remain in the dark. This disparity is more than a social challenge; for an entrepreneur with foresight, it’s a compelling business opportunity centered on local manufacturing.

Approximately 15% of the Bolivian population, primarily in remote communities scattered across the Andes mountains and the Amazon basin, lacks access to the national electricity grid. Extending conventional power lines to these areas is often economically and logistically unfeasible. This reality has prompted the Bolivian government and its partners to embrace a more practical solution: decentralized solar power. This article makes the business case for establishing a solar module factory in Bolivia to supply this growing and predictable domestic market.

Table of Contents

Understanding the Landscape: Rural Electrification in Bolivia

To fully appreciate the opportunity, it is essential to understand the context driving this demand. Bolivia’s geography is a defining factor. The immense cost and technical difficulty of extending the grid over mountains and through dense rainforests have made off-grid solutions a national priority.

The government has formalized this priority through initiatives like the Programa de Electrificación Rural (PER). These programs, often supported by international partners like the Inter-American Development Bank (IDB), aim to achieve universal electricity access. Their strategy relies heavily on renewable energy—particularly solar home systems and micro-grids—as the most efficient way to power remote households, schools, and health clinics.

Key actors in this landscape include:

- The Ministry of Hydrocarbons and Energies: Sets national policy and oversees electrification programs.

- Empresa Nacional de Electricidad (ENDE): The state-owned utility responsible for implementing many of these projects.

- International Development Banks & NGOs: Provide funding, technical expertise, and project management for rural initiatives.

This formal structure ensures projects are not speculative—they are defined, funded, and executed through public tenders, creating a clear and predictable demand for solar modules.

The Core Opportunity: From Import Dependency to Local Production

Currently, Bolivia imports the vast majority of its solar modules, predominantly from Asia. This reliance on foreign supply chains creates several inefficiencies and risks that a local manufacturer is perfectly positioned to address:

- Long Lead Times: Shipping modules across the globe can take months, delaying critical electrification projects.

- Logistical Hurdles: Managing international freight, customs clearance, and inland transportation to remote sites is complex and costly.

- Supply Chain Vulnerability: Global events, from shipping crises to trade disputes, can disrupt the availability and pricing of essential components.

A domestic manufacturing facility bypasses these issues. The primary product needed for this market is a standard solar module for use in simple solar home systems. These systems typically provide essential power for lighting, charging mobile phones, and running small appliances, fundamentally transforming the quality of life for rural families.

By producing these modules within Bolivia, a local enterprise can offer a more responsive, reliable, and competitive solution.

Strategic Advantages of a Local Solar Module Factory

An entrepreneur establishing a solar module factory in Bolivia would compete on more than just price. The value proposition rests on several strategic advantages that government and NGO project managers will find compelling.

Reduced Logistical Complexity and Lead Times

The ability to deliver modules from an in-country factory directly to project sites is a significant competitive edge. It shortens project timelines, reduces inventory costs for contractors, and simplifies overall project management.

Alignment with National Industrial Policy

Governments worldwide, including Bolivia’s, favor initiatives that promote local industry, create skilled jobs, and reduce reliance on imports—a policy known as import substitution. A local factory creating sought-after Bolivian factory products like solar modules aligns perfectly with these national goals, a position that can lead to preferential treatment in public procurement processes.

Customization and Local Support

A local manufacturer can offer products specifically adapted to Bolivia’s diverse environments, such as modules designed for optimal performance at high altitudes in the Andes or with enhanced durability for the humid Amazonian climate. Offering local technical support and warranty services provides a level of assurance that foreign suppliers cannot match.

Navigating the Market: Key Considerations for Entry

Entering this market requires more than technical production capabilities; it demands a clear understanding of the business environment and its unique processes.

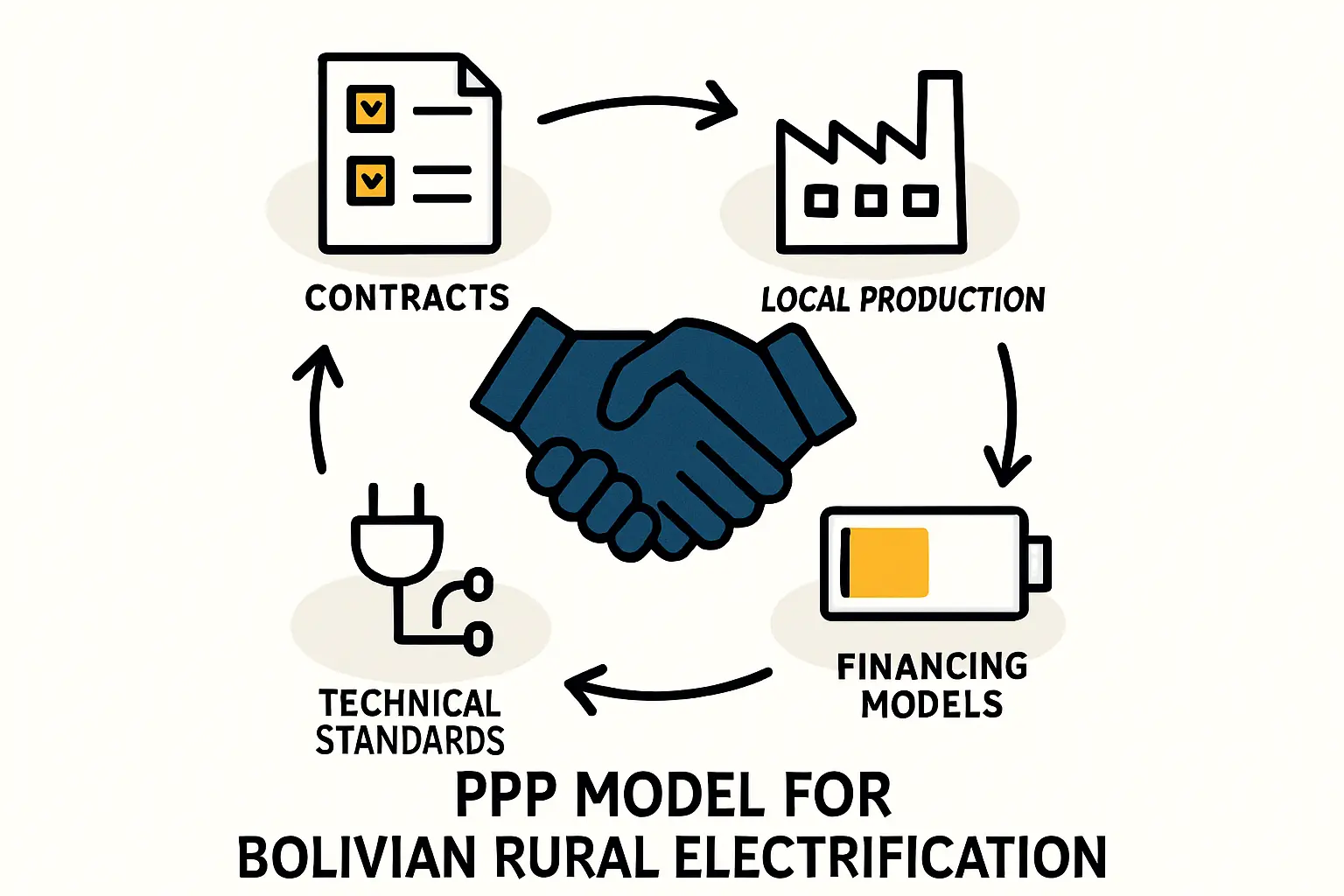

Public Procurement and Tenders

Success hinges on navigating the public tender process. This involves monitoring announcements from entities like ENDE, preparing detailed and compliant bids, and understanding the evaluation criteria. The process is typically structured and transparent, rewarding bidders who can reliably meet technical specifications and delivery schedules.

Quality and Certification

Government and internationally-funded projects require solar modules to meet global quality and safety standards. Securing the necessary IEC certifications is not an option but a prerequisite for participating in public tenders. This ensures the products are durable, reliable, and perform as specified over their intended 25-year lifespan.

Building Strategic Relationships

Developing professional relationships with decision-makers at the Ministry of Energies, ENDE, and key NGOs is crucial. These stakeholders value reliable partners who understand local needs and can contribute to the success of national electrification goals.

A Practical Look at Implementation

The prospect of building a factory may seem daunting, especially for those without a background in solar technology. However, the path is more accessible than it appears.

This business model is well-suited to establishing a small-scale solar module factory, perhaps in the 20–50 MW annual capacity range. A facility of this size can supply a significant portion of the rural electrification demand without requiring the massive capital outlay of a gigawatt-scale plant.

Understanding the investment requirements is a critical first step. Experience from projects by J.v.G. Technology GmbH shows that a facility of this scale can be established with a structured plan. For entrepreneurs who are experts in business but not in PV engineering, a turnkey solar manufacturing line provides a comprehensive solution. This approach bundles the machinery, process training, and quality assurance systems, enabling a new enterprise to become operational in less than a year.

Frequently Asked Questions (FAQ)

Q: What factory size is most suitable for the Bolivian market?

A: A small to medium-sized line with an annual capacity of 20–50 MW is an excellent starting point. This capacity is large enough to be competitive for government tenders yet nimble enough to keep initial investment and operational complexity manageable. The facility should be designed for future expansion as demand grows.

Q: Do I need a technical background in solar energy to succeed?

A: Not necessarily. Many successful factory owners come from other business sectors. The key requirements are strong business acumen, project management skills, and the ability to secure financing. The technical aspects of production can be handled by a qualified operations team and an experienced turnkey provider.

Q: How long does it take for a new factory to become operational?

A: With a clear plan and a turnkey partner, a new factory can realistically go from initial decision to full production in approximately 9 to 12 months. This timeline includes factory planning, machine procurement and shipping, installation, and staff training.

Q: Are there specific module requirements for projects in Bolivia?

A: While tender documents will always provide the definitive specifications, modules used in Bolivia may benefit from designs that account for high UV radiation and pressure differentials at high altitudes or enhanced moisture protection for jungle environments. A local manufacturer is uniquely positioned to address these specific needs.

Conclusion: The Path Forward

The need for rural electrification in Bolivia presents a clear, government-backed market opportunity for a local solar module manufacturer. This is not about speculative growth, but about supplying a defined need within a structured procurement framework.

By replacing unreliable import chains with local production, an entrepreneur can build a profitable enterprise with significant strategic advantages in logistics, policy alignment, and customer service. More importantly, this venture contributes directly to a national priority, bringing light and opportunity to thousands of families. For the right business professional, this represents a chance to build a lasting industrial asset while making a tangible impact on the country’s development.