When planning a new solar module factory, entrepreneurs often focus on high-tech components like photovoltaic cells and specialized glass. Yet a significant competitive advantage lies in an often-overlooked area: the local sourcing of structural components.

The aluminum frame, while seemingly simple, offers a key opportunity to reduce costs, strengthen the supply chain, and support the regional economy.

This article examines the strategic potential of leveraging a country’s existing industrial strengths, using Bosnia and Herzegovina’s robust aluminum sector as a practical case study. It outlines the benefits, challenges, and due diligence required to integrate local suppliers into a solar manufacturing operation.

Table of Contents

The Strategic Role of the Aluminum Frame in Solar Modules

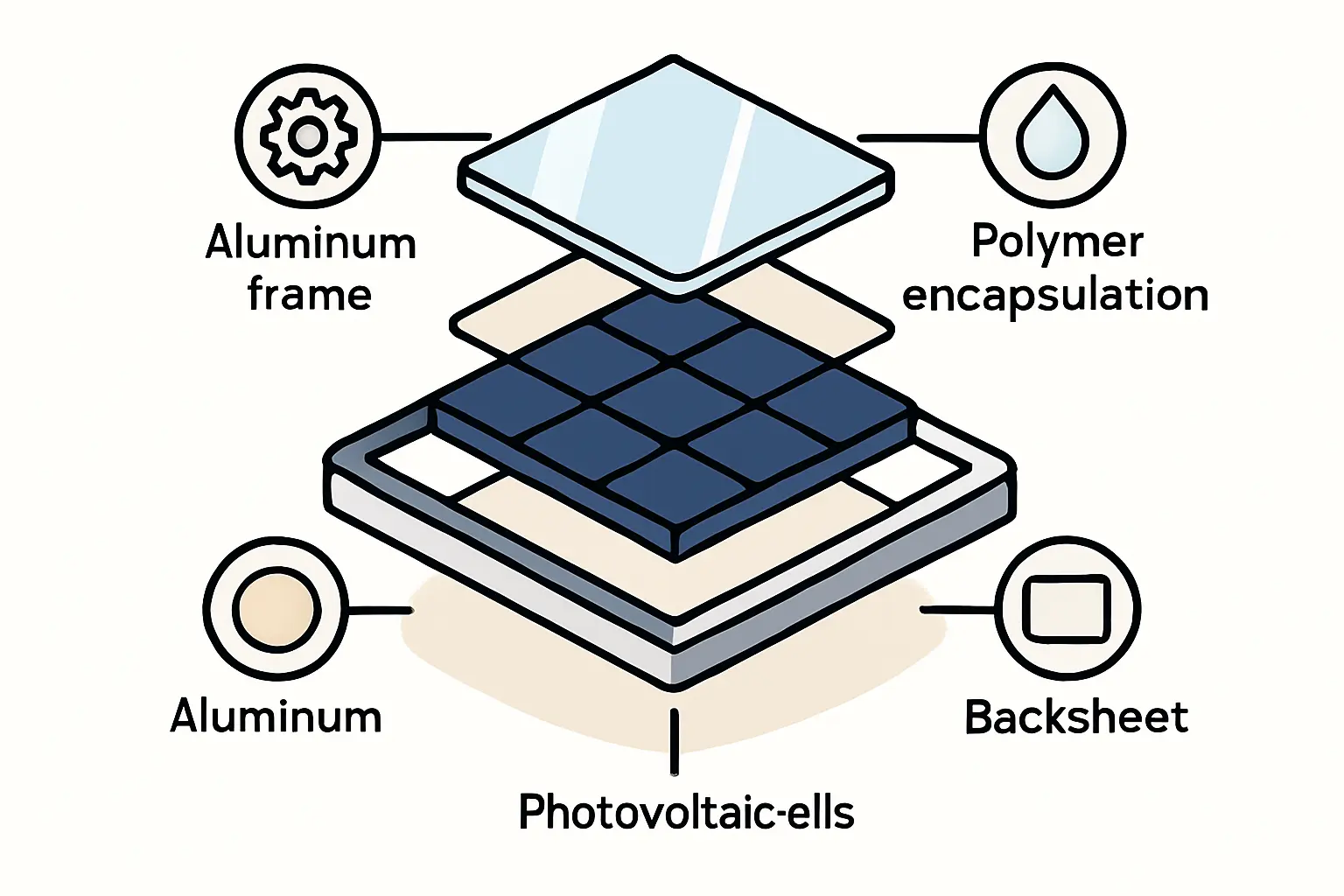

An aluminum frame’s primary function is to provide structural integrity and protection for the solar module. It safeguards the delicate laminate—comprising glass, encapsulant, and solar cells—from mechanical stresses like wind and snow loads, as well as from impacts during transportation and installation.

The frame also serves as the primary mounting structure, allowing the module to be securely fastened to racking systems. While not an electronic component, the frame is critical to the module’s durability and longevity. Its design, material quality, and precision directly influence the final product’s reliability and bankability.

From a logistics perspective, aluminum frames are bulky and relatively heavy for their value. Shipping them from established manufacturing hubs in Asia to facilities in Europe, Africa, or the Americas adds considerable cost and complexity to the supply chain. This is precisely where the opportunity for local sourcing emerges.

The Case for Local Sourcing: An Analysis of Bosnia and Herzegovina

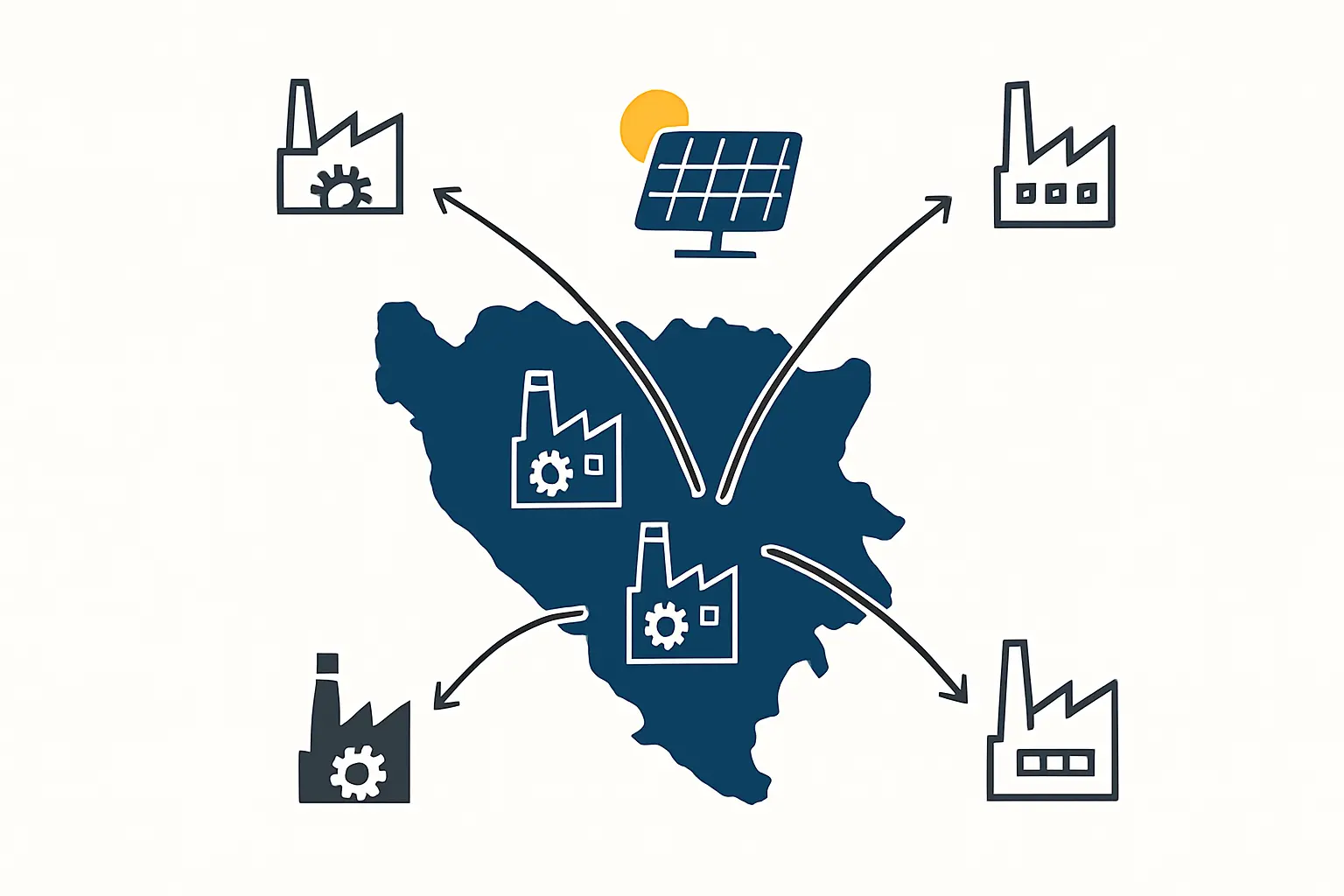

The industrial landscape of Bosnia and Herzegovina (BiH) provides a compelling case study. The country has a long-standing, well-developed aluminum industry, making it a significant producer and exporter in the Balkan region.

Major companies like Aluminij Mostar, Feal Široki Brijeg, and Alpro Vlasenica have established capabilities for producing a wide range of extruded aluminum profiles for the construction, automotive, and other industrial sectors. Their expertise in profile extrusion is directly transferable to manufacturing frames for solar modules.

An entrepreneur investigating how to start a solar panel factory in this region could explore partnerships with these local players. Instead of importing frames, they could source them from a supplier just a few hundred kilometers away, fundamentally changing their operational model.

Tangible Business Advantages of a Local Supply Chain

Shifting the sourcing of aluminum frames from international importers to local producers offers several compelling business advantages that any thorough solar panel manufacturing business plan should evaluate.

Key Benefits of Local Sourcing:

- Reduced Logistics Costs: Eliminating transcontinental shipping significantly cuts freight expenses, import duties, and associated administrative overhead, directly lowering the cost per module.

- Shorter Lead Times and Increased Flexibility: A local supply chain shrinks delivery times from months to weeks or even days. This agility allows a factory to better manage inventory and respond more quickly to changes in demand or module design.

- Enhanced Supply Chain Resilience: Relying on long-distance shipping exposes a business to global disruptions, from port congestion to geopolitical instability. Local sourcing creates a more robust and predictable supply chain.

- Support for the Local Economy: For projects with state involvement or those seeking development financing, demonstrating a commitment to local industry can be a significant advantage. This approach creates local jobs and contributes to the regional industrial ecosystem.

Key Considerations and Technical Challenges

While the benefits are clear, successfully integrating a local aluminum supplier requires careful planning and rigorous technical oversight. The requirements for photovoltaic applications are more stringent than those for general construction.

1. Quality Assurance and Specification Matching

The primary challenge is ensuring the local supplier can meet the precise technical specifications for PV-grade frames. This involves:

- Alloy Composition: The aluminum alloy must offer the right balance of strength and corrosion resistance.

- Profile Tolerances: The dimensions of the extruded profile must be exact to ensure a perfect fit with the glass laminate and backsheet.

- Anodization Quality: The thickness and uniformity of the anodized coating are critical for long-term weather and corrosion resistance. A comprehensive solar panel quality control process must, therefore, include diligent inspection of incoming frames.

2. Supplier Vetting and Capability Audits

Not every aluminum extruder can meet these standards. Experience from J.v.G. turnkey projects shows that the vetting process is a crucial step. It involves a multi-stage audit to assess a potential supplier’s manufacturing processes, quality control systems, and ability to scale production to meet the factory’s demand. Initial sample batches must be thoroughly tested before a long-term supply agreement is signed.

3. Price Volatility and Contracting

The price of raw aluminum is tied to global markets, primarily the London Metal Exchange (LME). Contracts with local suppliers must include clear pricing mechanisms that account for this volatility, protecting both the module manufacturer and the supplier from unpredictable cost fluctuations.

While the initial cost of a solar panel manufacturing plant is heavily influenced by machinery, ongoing operational costs for raw materials determine long-term profitability. Optimizing the frame supply is a key part of managing these operating expenses.

Frequently Asked Questions (FAQ)

Q: What is an aluminum frame’s main purpose on a solar panel?

A: Its primary purpose is to protect the solar laminate mechanically, ensure structural rigidity against environmental loads like wind and snow, and provide a standardized structure for mounting the panel.

Q: Are all aluminum profiles suitable for solar modules?

A: No. Solar module frames require specific aluminum alloys for durability and corrosion resistance. The anodization layer must also be of a certain thickness (typically 15 microns or more) to withstand decades of outdoor exposure.

Q: How much does the frame contribute to the total module cost?

A: The frame typically accounts for 8–12% of a solar module’s total material cost. However, its bulk and weight mean that its contribution to logistics costs can be disproportionately high, making local sourcing particularly impactful.

Q: Can sourcing frames locally reduce my initial investment?

A: Local sourcing primarily affects operational costs (cost per module) rather than the initial capital expenditure for equipment. However, it can simplify your initial supply chain setup and reduce the working capital needed for inventory in transit. For businesses considering turnkey solar manufacturing lines, integrating local suppliers from day one is a powerful strategic decision.

Building a Resilient and Cost-Effective Operation

The decision to establish a solar module factory is a significant undertaking. While the focus is often on core technology, strategic supply chain decisions can define the long-term success and profitability of the venture.

The case of Bosnia and Herzegovina’s aluminum sector demonstrates a universal principle: leveraging local industrial strengths can create a powerful competitive advantage. By carefully vetting and developing partnerships with regional suppliers, entrepreneurs can build more resilient, cost-effective, and locally integrated manufacturing operations. This approach requires diligence and technical oversight but offers substantial rewards in an increasingly competitive global market.