Industrial operators in remote regions often rely on diesel generators, a solution plagued by complex fuel logistics, volatile costs, and the significant business risk of operational interruptions.

At a large-scale mine in Botswana, a power failure can halt production, costing hundreds of thousands of dollars per hour. In a remote community, an unreliable power source can disrupt essential services like water pumping, healthcare, and education.

Solar photovoltaics offer a logical solution, promising energy independence and stable costs. But Botswana’s unique environmental conditions mean that not all solar modules are suitable for these critical applications.

Standard, mass-market panels, typically designed for moderate European climates, often suffer rapid degradation and premature failure when exposed to the region’s intense heat, dust, and UV radiation. Understanding the specific technical requirements is crucial for any entrepreneur looking to serve this demanding but rewarding market.

Table of Contents

Why Standard Solar Modules Often Underperform in Botswana

The operational environment in Botswana, particularly for mining and off-grid installations, presents a combination of challenges that push solar modules to their structural and electrical limits. Simply selecting a panel based on its peak power output (Wp) is insufficient; a deeper understanding of its material science and design is crucial.

Three primary environmental factors contribute to accelerated module degradation:

-

High Ambient Temperatures and Irradiance: Botswana experiences some of the highest levels of solar irradiance in the world—excellent for energy production. This is coupled with high ambient temperatures, often exceeding 40°C. Solar cells lose efficiency as they get hotter, and sustained high temperatures accelerate the aging of module components like encapsulants and backsheets.

-

Mechanical Stress Factors: Mining operations involve constant vibration, airborne dust, and the risk of impact from small debris. Transportation to remote off-grid sites over unpaved, rough terrain places significant mechanical stress on the module’s frame, glass, and internal cell connections. Seasonal hailstorms also pose a direct threat.

-

Intense Ultraviolet (UV) Radiation: The high altitude and clear skies lead to intense UV exposure. Over time, UV radiation can cause the encapsulant material protecting the solar cells to yellow or delaminate, reducing light transmission and causing significant power loss.

Key Technical Specifications for High-Reliability Modules

To withstand these conditions, modules must be engineered with features that go beyond standard consumer-grade products. For an investor planning to enter this sector, focusing on producing modules with these specifications can create a significant competitive advantage.

Superior Thermal Performance and Durability

The impact of heat on a module’s output is measured by its temperature coefficient. A lower coefficient means the module performs better at high temperatures. Aim for modules with a temperature coefficient of -0.35%/°C or lower; standard modules are often -0.45%/°C or higher.

High heat and humidity also accelerate a phenomenon known as Potential-Induced Degradation (PID), which can cause a severe drop in power output. Selecting PID-resistant or PID-free cells and materials is critical for long-term performance in Botswana’s climate.

Robust Mechanical Design

A module’s structural integrity is paramount. Key components to focus on include:

-

Frame: A thicker, anodized aluminum frame (e.g., 40 mm instead of the standard 30-35 mm) with reinforced corner joints provides greater resistance to twisting and bending during transport and in high winds.

-

Glass: The front glass should be high-transparency, tempered, and at least 3.2 mm thick to withstand hail impact. An anti-reflective (AR) coating can also improve light capture, especially during early morning and late afternoon.

-

Junction Box: A high-quality junction box with an IP67 or IP68 rating ensures dust and moisture cannot penetrate and corrode the electrical connections, a common point of failure.

Advanced Material Selection: Glass-Glass Construction

One of the most significant design choices for durability is a glass-glass (or dual-glass) module construction. Unlike conventional glass-backsheet modules, these panels sandwich the solar cells between two sheets of heat-strengthened glass.

The advantages of this design for environments like Botswana are clear:

-

Impermeable Rear Side: The rear glass sheet provides a perfect barrier against moisture and mechanical damage, unlike a polymer backsheet that can be scratched or degraded over time.

-

Improved Fire Resistance: Glass-glass modules typically have a higher fire safety rating (Class A).

-

Enhanced Durability: The symmetric structure reduces mechanical stress on the solar cells, making them far more resistant to microcracks caused by vibration or impact.

When evaluating materials, the choice of encapsulant—the polymer that bonds the cells to the glass—is also a critical consideration. While EVA (Ethylene Vinyl Acetate) is common, POE (Polyolefin Elastomer) offers superior resistance to moisture ingress and PID, making it a better choice for long-life glass-glass modules.

The Role of Certification in Ensuring Quality

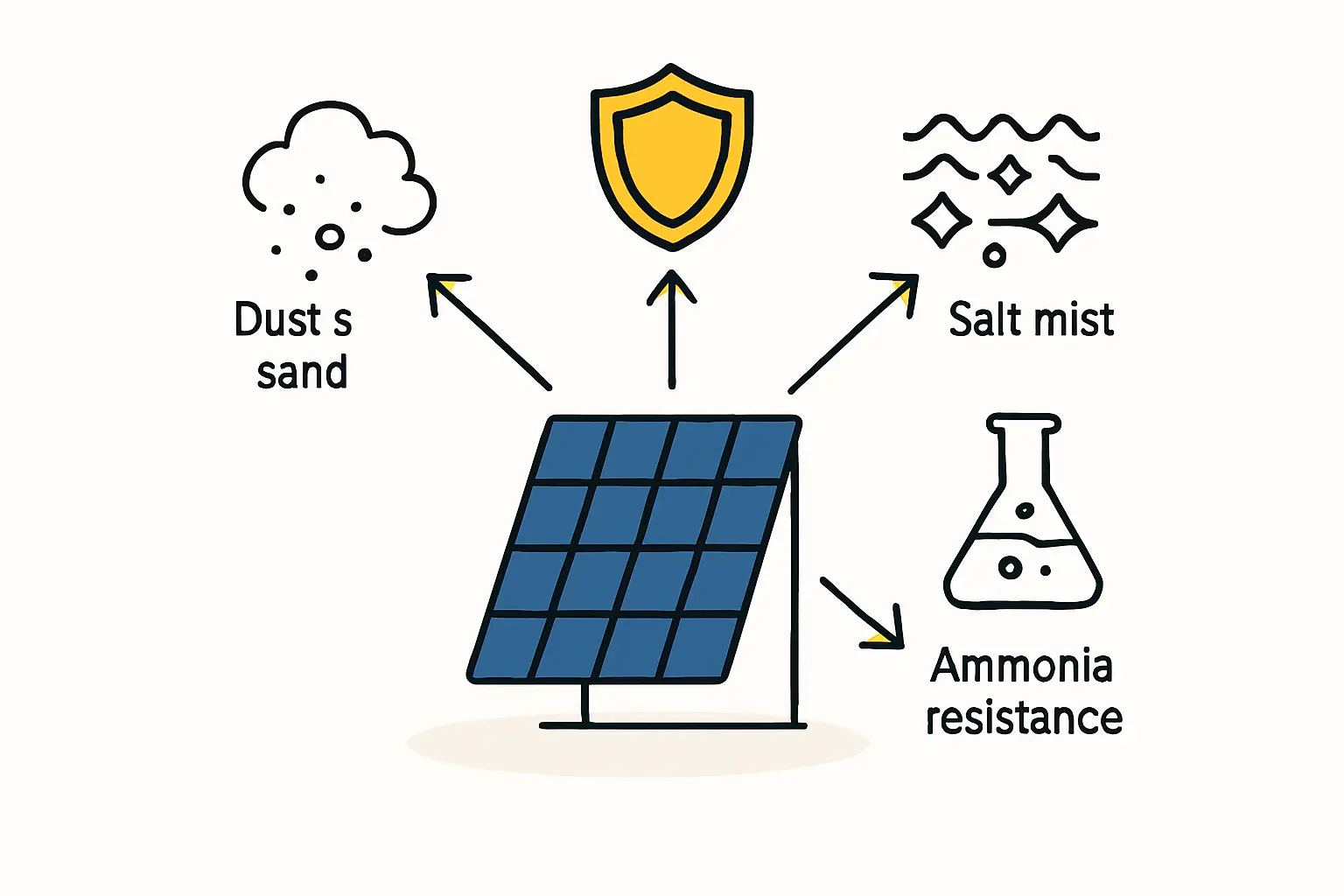

For industrial and commercial projects, independent verification of a module’s quality is non-negotiable. While many modules meet basic standards, those intended for harsh environments should have extended or specialized certifications.

-

IEC 61215 (Performance): Confirms the module’s electrical and thermal characteristics under testing.

-

IEC 61730 (Safety): Verifies the module’s safety for installers and operators.

-

IEC 61701 (Salt Mist Corrosion Test): While Botswana is not a coastal region, the atmospheric conditions in some mining areas can be corrosive. This certification provides an extra layer of assurance.

-

IEC 62716 (Ammonia Corrosion Test): Important for agricultural or certain industrial sites.

-

IEC TS 62941 (Quality Management System): This standard goes beyond the product to certify the quality systems of the manufacturer. It is a strong indicator of consistent production.

Implementing a rigorous solar panel quality control system that adheres to these standards is fundamental to building a reputable manufacturing operation.

The Business Case: From Capital Cost to Levelized Cost of Energy (LCOE)

A common mistake for new investors is focusing solely on the upfront cost per watt of a solar module. For a 25- to 30-year asset, the true measure of financial viability is the Levelized Cost of Energy (LCOE).

LCOE calculates the total cost to produce a kilowatt-hour (kWh) of electricity over a project’s lifetime, accounting for the initial investment, maintenance, and total energy produced.

A cheaper, lower-quality module might fail after eight years in a harsh environment. In contrast, a more robust, slightly more expensive module that performs reliably for 25 years will produce far more energy over its life, delivering a significantly lower LCOE and a much higher return on investment.

For mine operators and financiers, a predictable LCOE is critical for de-risking a project. Therefore, the overall cost of setting up a solar panel factory should be planned with the primary goal of producing modules that deliver a competitive LCOE for the end customer.

The Opportunity for Local Manufacturing in Botswana

Botswana’s government has shown strong interest in developing local industrial capacity. By establishing a manufacturing facility focused on producing high-reliability modules tailored to local conditions, an entrepreneur can address a clear market need.

A local factory offers significant advantages:

-

Reduced Logistics Costs: Eliminates expensive and risky international shipping of fragile modules.

-

Customization: The ability to produce modules specifically engineered for the regional climate.

-

Faster Lead Times: Improved supply chain responsiveness for large projects.

-

Local Support and Service: Providing technical support and warranty fulfillment from within the country builds immense trust.

Based on experience from J.v.G. turnkey projects, a well-planned turnkey solar manufacturing line can be configured specifically to produce these robust glass-glass modules, giving a new market entrant a powerful technical and commercial advantage.

Frequently Asked Questions

What is Potential-Induced Degradation (PID)?

PID is a performance loss in solar modules caused by voltage differences between the solar cell and the module’s frame. This “stray current” can reduce a module’s power output by up to 30% or more. This effect is accelerated by high temperatures and humidity, making PID-resistant materials a necessity in hot climates.

What does an IP68 rating on a junction box mean?

The IP (Ingress Protection) rating classifies the level of protection against intrusion from foreign bodies (like dust) and water. The first digit (6) means it is completely dust-tight. The second digit (8) means it can be submerged in water under specified pressure for extended periods. An IP68 rating is the highest standard for junction boxes, ensuring long-term reliability against the elements.

Is a glass-glass module much heavier than a standard module?

Yes, a glass-glass module is typically heavier because the lightweight polymer backsheet is replaced with a second sheet of glass. This needs to be factored into the design of the mounting structure. However, the immense gains in durability, lifespan, and reliability often justify the additional weight and structural considerations, especially for stationary, long-term installations.

Can these specialized modules be produced in a small- to medium-sized factory?

Absolutely. Modern, semi-automated production lines are scalable and can be designed to handle different module types, including glass-glass. A starting capacity of 20-50 MW per year is a common entry point for new manufacturers and is well-suited to producing high-quality, specialized modules for regional industrial and commercial markets.

Next Steps in Planning Your Venture

Understanding the technical nuances of solar modules required for Botswana’s industrial sector is the foundation for a successful business plan. The market does not need another importer of standard panels; it needs a local producer of reliable, long-lasting energy solutions. A focus on quality engineering, robust materials, and certified performance will establish a new manufacturing venture as a critical partner in the region’s sustainable development.