Disclaimer: This case study represents a composite example derived from real-world

consulting work by J.v.G. Technology GmbH in solar module production and factory optimization. All data points are realistic but simplified for clarity and educational purposes.

For entrepreneurs looking to enter Brazil’s rapidly expanding solar market, one reality quickly becomes clear: financing is the key that unlocks growth. The Brazilian Development Bank (BNDES) and its FINAME credit line are the primary source of this financing.

However, accessing these funds requires navigating a complex set of local content rules known as credenciamento. This process can seem daunting for an entrepreneur unfamiliar with photovoltaic manufacturing. The challenge is not simply financial; it is technical and logistical. Successfully structuring a project for BNDES approval demands a deep understanding of production processes, supply chains, and technical documentation. This article outlines a strategic approach to establishing a BNDES-compliant solar module factory in São Paulo, transforming a regulatory hurdle into a competitive advantage.

Understanding the BNDES Framework for Solar Manufacturing

The BNDES is a federal public company that provides long-term financing for projects contributing to Brazil’s development. For the solar industry, its FINAME credit line is pivotal. It offers favorable financing terms to purchasers of capital goods, provided those goods are manufactured in Brazil and meet specific nationalization criteria.

For a solar module to qualify for FINAME, the manufacturer must undergo a certification process called credenciamento. This certifies that the product and the production process adhere to the BNDES Productive Process (PPB) guidelines, which mandate a significant level of local content and manufacturing activity within Brazil. For an investor, having this certification means their customers can access preferential BNDES financing, making their modules far more competitive in the domestic market.

The Core Challenge: Meeting BNDES Local Content Requirements

At their core, the BNDES requirements are designed to ensure that a significant portion of a solar module’s value and material originates in Brazil. This is measured by a strict set of criteria that goes beyond simple final assembly.

Deconstructing the Credenciamento Process

The BNDES evaluates local content for each component of a solar module using two primary metrics: weight and price. To achieve certification, a manufacturer must meet minimum localization thresholds in both categories. The rules are designed to stimulate the local supply chain for bulkier, less technologically intensive components while allowing for the import of high-tech items like photovoltaic cells.

Typical requirements under BNDES FINAME rules include:

-

Local Sourcing of Key Components: The aluminum frames, junction boxes, solar glass, and backsheets (or a second glass pane for glass-glass modules) must generally be sourced from Brazilian suppliers.

-

Importation of Solar Cells: The regulations permit the importation of solar cells, which are the most technologically complex and capital-intensive part of the module.

-

Mandatory Local Manufacturing Steps: The entire process of cell stringing, bussing, lamination, framing, and testing must be performed in the Brazilian factory.

The Importance of a Compliant Bill of Materials (BOM)

Central to the BNDES application is a detailed Bill of Materials (BOM). This document lists every single component, its supplier, its country of origin, its weight, and its cost. The BNDES uses the BOM to calculate the local content indices. An incomplete or non-compliant BOM is a primary reason for application rejection.

Developing a compliant BOM requires tight integration between the technical plan for the factory and the procurement strategy for sourcing materials. For a detailed breakdown of capital requirements, you can find more information in our guide on solar factory investment.

Structuring the Project for BNDES Approval: A Step-by-Step Approach

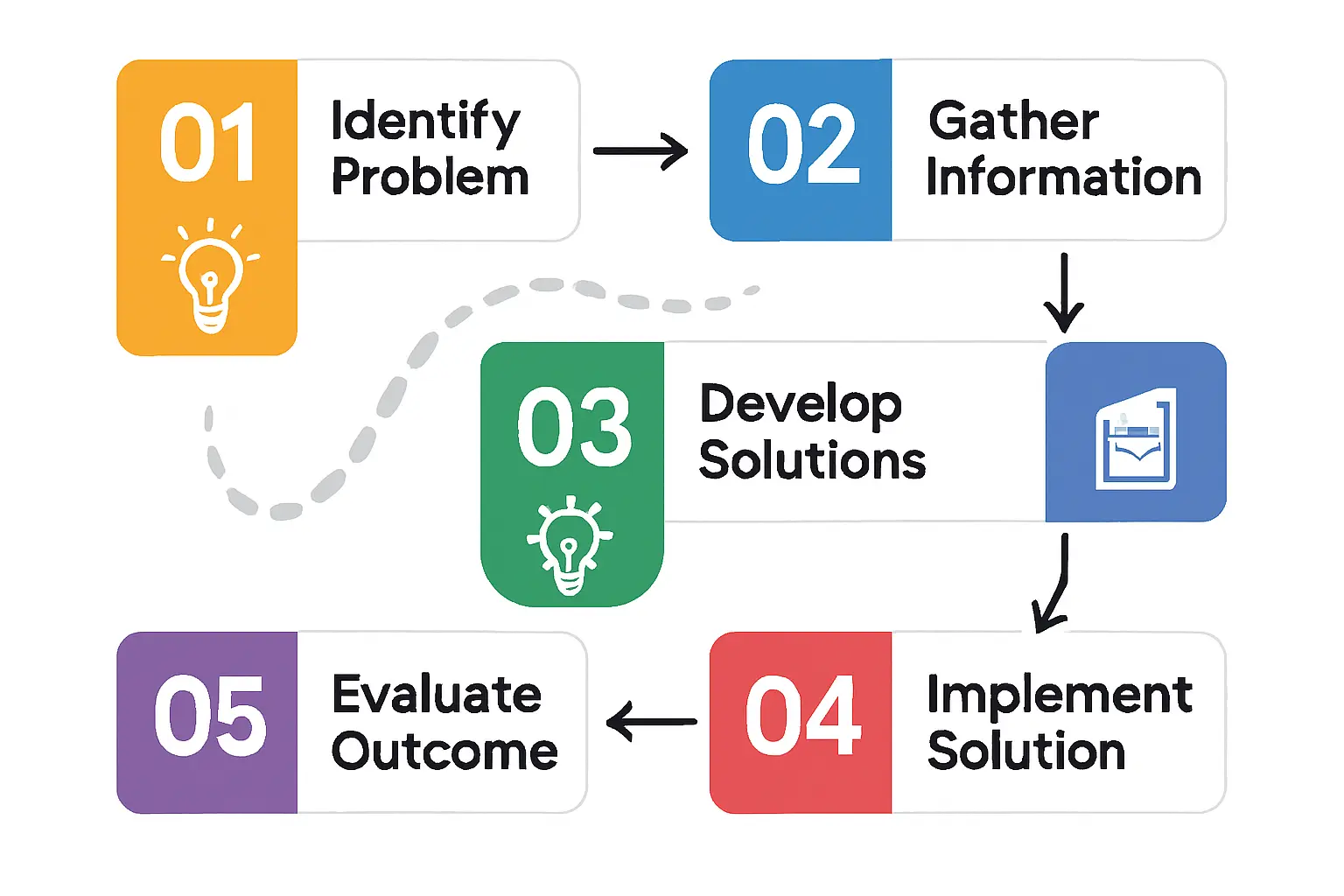

A successful BNDES application hinges on a well-structured project plan. Based on experience gained from European PV manufacturers’ turnkey projects, the process can be broken down into clear, manageable phases.

Phase 1: Feasibility and Business Plan Development

Before any equipment is ordered, the first step is to create a robust business plan. This plan serves not only the investor’s internal strategy but also forms the basis of the BNDES application. It should include:

-

A thorough market analysis of the Brazilian solar sector.

-

Detailed financial projections, including CAPEX, OPEX, and revenue forecasts.

-

A preliminary site selection analysis, with strong consideration for the logistical advantages of states like São Paulo.

-

A high-level overview of the proposed production technology and capacity.

Phase 2: Technical Project Design and Partner Selection

This phase translates the business plan into a detailed technical specification. It involves designing the factory layout, defining the process flow, and selecting the machinery. At this stage, a technical partner with experience in BNDES compliance becomes critical. The partner helps ensure that the selected solar module production line machines and processes meet the bank’s stringent requirements. The complete journey from concept to operation is detailed in our overview of how to start a solar factory.

Phase 3: Sourcing Strategy and Supply Chain Setup

In parallel with the technical design, the investor must identify and qualify local suppliers for the mandated components like glass, frames, and junction boxes. This is often a significant challenge in emerging markets. An experienced partner can assist by providing specifications for suppliers and helping to audit their capabilities, ensuring they can deliver the required quality and volume.

The Role of the Technical Partner in Ensuring Compliance

Navigating the BNDES process without prior experience is a high-risk endeavor. A technical partner like an experienced European turnkey engineering team provides the engineering expertise and procedural knowledge needed for a smooth and successful application.

Providing Essential Technical Documentation

The BNDES requires exhaustive documentation for every piece of equipment and every step of the manufacturing process. This includes machine specifications, process flow diagrams, quality control procedures, and layout plans. A turnkey line provider supplies this entire package of documentation in the precise format required by the bank, eliminating guesswork and potential errors.

Navigating the BNDES Application and Audit Process

An experienced partner guides the entrepreneur through the formal application submission. More importantly, they help prepare for the physical audit, where BNDES technicians visit the factory to verify that the implemented processes and equipment match the submitted documentation. This guidance is invaluable in preventing delays or rejection due to non-conformities.

From Approval to Operation: Turnkey Implementation

Once BNDES approval is secured, the technical partner manages the complete project execution. This includes machine installation, commissioning, staff training, and process optimization to ensure the factory is not only compliant on paper but also operates efficiently and produces high-quality, certified solar modules from day one.

Why São Paulo State is a Strategic Location

For a solar manufacturing venture in Brazil, São Paulo offers distinct advantages. Its mature industrial infrastructure provides a qualified labor pool and a network of potential suppliers for components like aluminum frames and glass. Furthermore, its central location and superior logistics network, including the Port of Santos, facilitate both the import of machinery and cells and the distribution of finished modules across Brazil.

Frequently Asked Questions (FAQ)

What is the typical timeline for BNDES approval?

The timeline can vary, but with a well-prepared application and an experienced partner, the process from submission to approval typically takes four to six months. The entire project, from planning to the start of production, can often be completed in under 12 months.

Can I use imported machinery and still be compliant?

Yes. BNDES rules focus on the local content of the final product (the solar module), not the machinery used to produce it. Investors are free to import the best available production technology to ensure efficiency and quality.

What is the minimum factory size BNDES will consider for financing?

While there is no official minimum, projects with an annual capacity of 50 MW or more are generally viewed as more viable from a commercial and industrial standpoint. The business plan must demonstrate long-term sustainability.

Does a technical partner like an EU PV factory turnkey supplier handle the BNDES application directly?

The application must be submitted by the Brazilian legal entity that owns the project. The role of the technical partner is to provide all necessary technical documentation, guidance, and project execution support to ensure the application is complete, accurate, and successful. The partner acts as the investor’s engineering backbone throughout the process.

Download the BNDES-Compliant Solar Factory Guide (PDF)

Author: This case study was prepared by the

turnkey solar module production specialists at J.V.G. Technology GmbH

It is based on real data and consulting experience from J.v.G. projects

worldwide, including installations ranging from 20 MW to 500 MW capacity.