Disclaimer: This case study represents a composite example derived from real-world

consulting work by J.v.G. Technology GmbH in solar module production and factory optimization. All data points are realistic but simplified for clarity and educational purposes.

Download the Brazil Distributed Generation Market Case Study (PDF)An entrepreneur looking at Brazil’s energy sector might see a landscape dominated by large-scale utility projects. However, the most dynamic growth is happening on a much smaller scale: on the rooftops of homes and businesses across the country. This segment, known as Distributed Generation (GD), presents a unique opportunity for entrepreneurs who can solve a critical gap in the local supply chain.

This article outlines a business case, modeled on the strategic approach of an entrepreneurial family, for establishing a medium-scale solar module factory designed to serve this booming B2B market. This approach demonstrates how a focused strategy, supported by a turnkey production setup, can create a defensible and profitable enterprise without directly competing with global manufacturing giants.

Understanding the Brazilian ‘Geração Distribuída’ (GD) Opportunity

Distributed Generation refers to electricity generated at or near the point of consumption. In Brazil, this primarily means rooftop solar photovoltaic (PV) systems on residential and commercial properties. The growth in this sector has been nothing short of explosive. In 2022 alone, solar installations grew by 150%, with DG accounting for 16.4 GW of the country’s 24 GW total solar capacity.

This expansion was significantly influenced by Law 14.300, which established a new regulatory framework for the sector. While the law’s transition period created a ‘gold rush’ for installations, it more importantly now provides the long-term stability and legal security necessary for sustained investment.

This market is not served by a few large players. Instead, it is highly fragmented and powered by thousands of small and medium-sized installation companies, often called ‘integrators.’ These local businesses are the true engine of Brazil’s rooftop solar revolution, and they represent the primary customer base for a new module manufacturer.

The Challenge for Local Installers: A Supply Chain Gap

While the market for installers is strong, their operations face significant challenges rooted in the supply chain. Most integrators in Brazil rely on imported solar modules, which exposes their businesses to several risks:

- Logistical Delays: International shipping, port congestion, and customs clearance create long and unpredictable lead times.

- Price Volatility: Fluctuations in currency exchange rates and shipping costs make it difficult to maintain stable pricing for their end customers.

- Inconsistent Availability: Access to the latest high-efficiency modules (e.g., 550W+ panels) can be sporadic, forcing installers to change their system designs and product offerings frequently.

- Capital Constraints: Installers must often pay for containers of modules upfront, tying up significant capital in inventory while it is in transit.

This environment creates a clear opening for a local manufacturer that can offer a stable, reliable, and accessible supply of high-quality solar panels.

A Turnkey Solution by a European Industrial Solutions Provider: A Strategic Entry Model

For an entrepreneur or business professional without a deep background in photovoltaics, the prospect of building a factory can seem daunting. This is where a strategic, de-risked approach becomes essential. A complete guide on how to start a solar panel manufacturing business provides a foundational overview of the necessary steps.

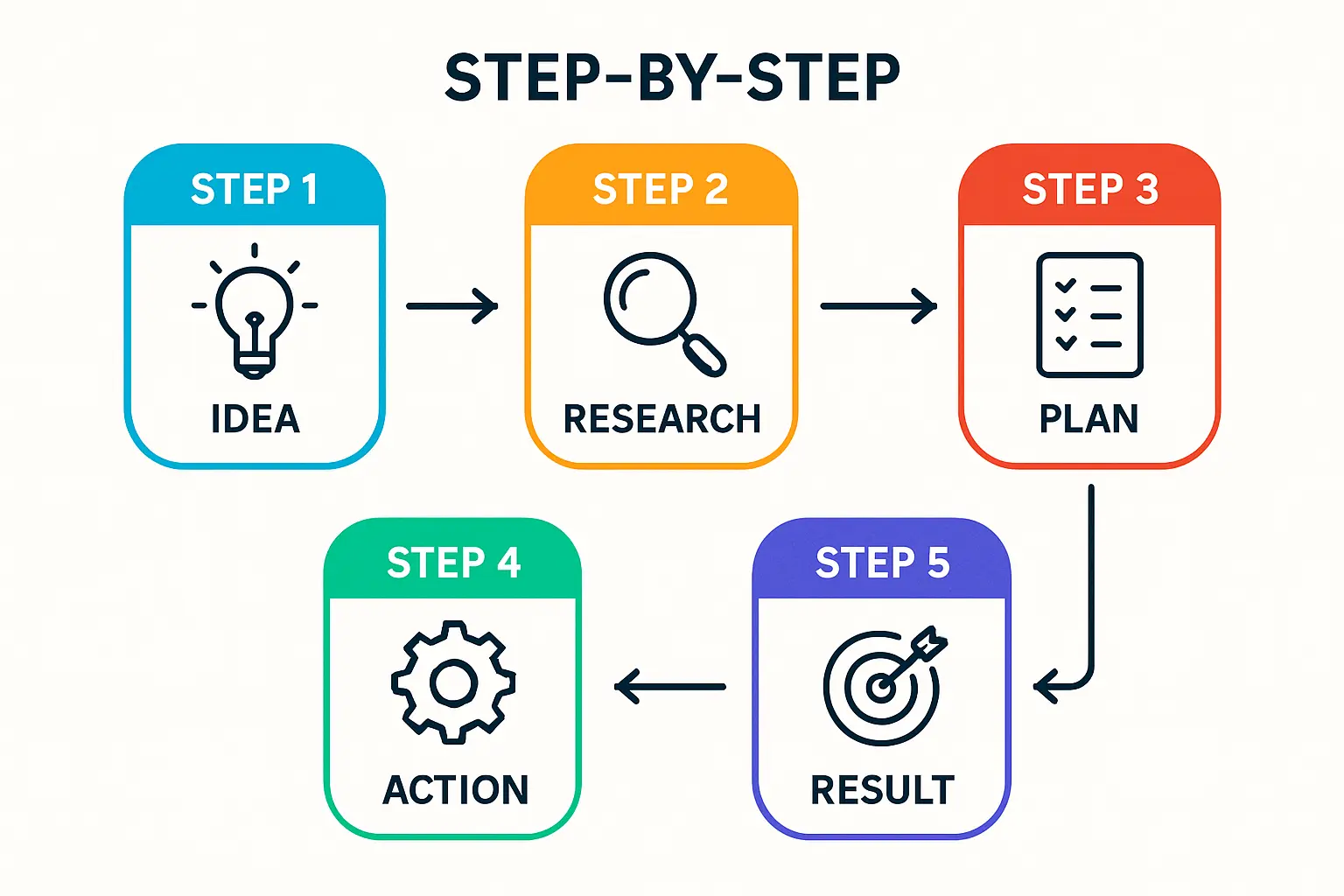

The business model explored here is based on three core principles:

- Serve a Niche: Instead of attempting to compete on price in the utility-scale market, the factory focuses exclusively on the needs of local GD installers.

- Build a B2B Partnership Network: The goal is not merely to sell a product but to become an indispensable partner to installers by providing reliability, technical support, and local stock.

- De-Risk Production: By implementing a proven turnkey solar manufacturing line, the business can bypass the steep learning curve associated with process engineering and machine selection.

This model allows the entrepreneur to concentrate on business development, distribution, and finance, while a proven turnkey system handles the technical complexities of production.

Phase 1: Building a B2B Distribution Network

The cornerstone of this business case is not the factory itself, but the distribution network it serves. The primary objective is to build a loyal base of 100-200 local installers by offering a value proposition that importers cannot match:

- Product on Demand: Maintaining local inventory allows installers to purchase modules as needed, improving their cash flow and reducing their own storage requirements.

- Technical Training & Support: The factory can serve as a center of excellence, offering training on the latest module technologies and providing direct support for warranty claims.

- Stable Pricing: By manufacturing locally, the business can offer more predictable pricing, insulated from the volatility of international freight and currency markets.

- Brand Loyalty: A locally produced, high-quality module with a strong brand name gives installers a competitive advantage in their own sales efforts.

This B2B-centric model transforms the relationship from a simple transaction into a long-term partnership, creating a strong competitive moat.

Phase 2: The Factory Setup and Operational Plan

The factory itself is designed specifically for this target market. A typical setup for this model would be a 20 MW to 50 MW line, which represents a balanced investment. An analysis of the solar panel manufacturing plant cost shows this scale is achievable without the massive capital expenditure required for gigawatt-level facilities.

Production would focus on high-efficiency modules (e.g., 550W and above) using modern cell technologies, as these products offer the best performance for space-constrained residential and commercial rooftops. The entire manufacturing process, from material handling to final testing, is engineered for quality and consistency.

A turnkey solution from an experienced engineering firm like an EU-based photovoltaic manufacturing solutions partner covers the entire technical setup:

- Factory layout and design.

- Selection and commissioning of all machinery.

- Training of local operators and technicians.

- Establishment of quality control protocols.

- Sourcing of certified raw materials.

This approach ensures the factory can be producing certified, high-quality modules in under 12 months.

Navigating Local Regulations and Financing

Establishing a local manufacturing presence in Brazil offers significant advantages beyond the supply chain. The Brazilian government often provides tax incentives for locally produced goods, which can reduce the cost of both raw material imports and final product sales.

Local production can also unlock access to favorable financing lines from national development banks like the BNDES (Banco Nacional de Desenvolvimento Econômico e Social). This is a powerful advantage, as these financing options can be extended to the factory’s installer customers, making it easier for them to purchase modules and grow their own businesses. A successful business plan must incorporate these local financial and regulatory instruments.

Frequently Asked Questions (FAQ)

Q1: Why not just import and distribute modules?

Importing and distributing is a viable business, but it operates on thinner margins and is more vulnerable to supply chain disruptions and competition. Local manufacturing provides greater control over product quality, branding, and supply. It also builds a more defensible long-term asset and can unlock tax and financing benefits unavailable to importers.

Q2: What is the typical investment for such a factory?

The investment depends on the chosen capacity and level of automation. For a 20–50 MW turnkey line, entrepreneurs should anticipate a capital requirement that covers machinery, building preparations, and initial working capital. A detailed breakdown can be found by examining typical solar panel manufacturing plant costs.

Q3: Does this factory produce the silicon solar cells?

No, this business model is for a module assembly plant. The factory imports solar cells—the most technologically complex component—and assembles them with other materials (glass, backsheet, frames) to produce finished modules. The solar cell manufacturing process is a far more capital-intensive undertaking, suited for very large, specialized corporations.

Q4: How long does it take to set up a turnkey factory?

With a clear plan and an experienced technical partner, a medium-scale factory can be operational in approximately 9 to 12 months from the finalization of contracts to the production of the first certified module.

From Market Gap to Market Leadership

The business case presented here illustrates a powerful principle: success in a high-growth market often comes not from competing with the largest players, but from identifying and serving a specific, underserved segment. Brazil’s fragmented network of solar installers represents just such an opportunity.

By developing a business model focused on partnership, reliability, and local production, a new entrant can solve critical pain points for these installers. A turnkey manufacturing solution de-risks the technical execution, freeing the entrepreneur to focus on building the commercial network that will drive long-term growth. This strategic approach provides a clear path from identifying a market gap to achieving a leadership position within a vital and expanding sector.

Download the Brazil Distributed Generation Market Case Study (PDF)

Author: This case study was prepared by the

turnkey solar module production specialists at J.V.G. Technology GmbH

It is based on real data and consulting experience from J.v.G. projects

worldwide, including installations ranging from 20 MW to 500 MW capacity.