Brazil’s solar energy market is undergoing an extraordinary expansion. With over 35 GW of installed capacity and an anticipated R$170 billion in new investments by 2026, the country presents a remarkable opportunity for entrepreneurs looking to enter the solar manufacturing sector.

For any new factory owner, however, a critical strategic question emerges: should components be sourced from Brazil’s developing local supply chain or through the complex process of importation?

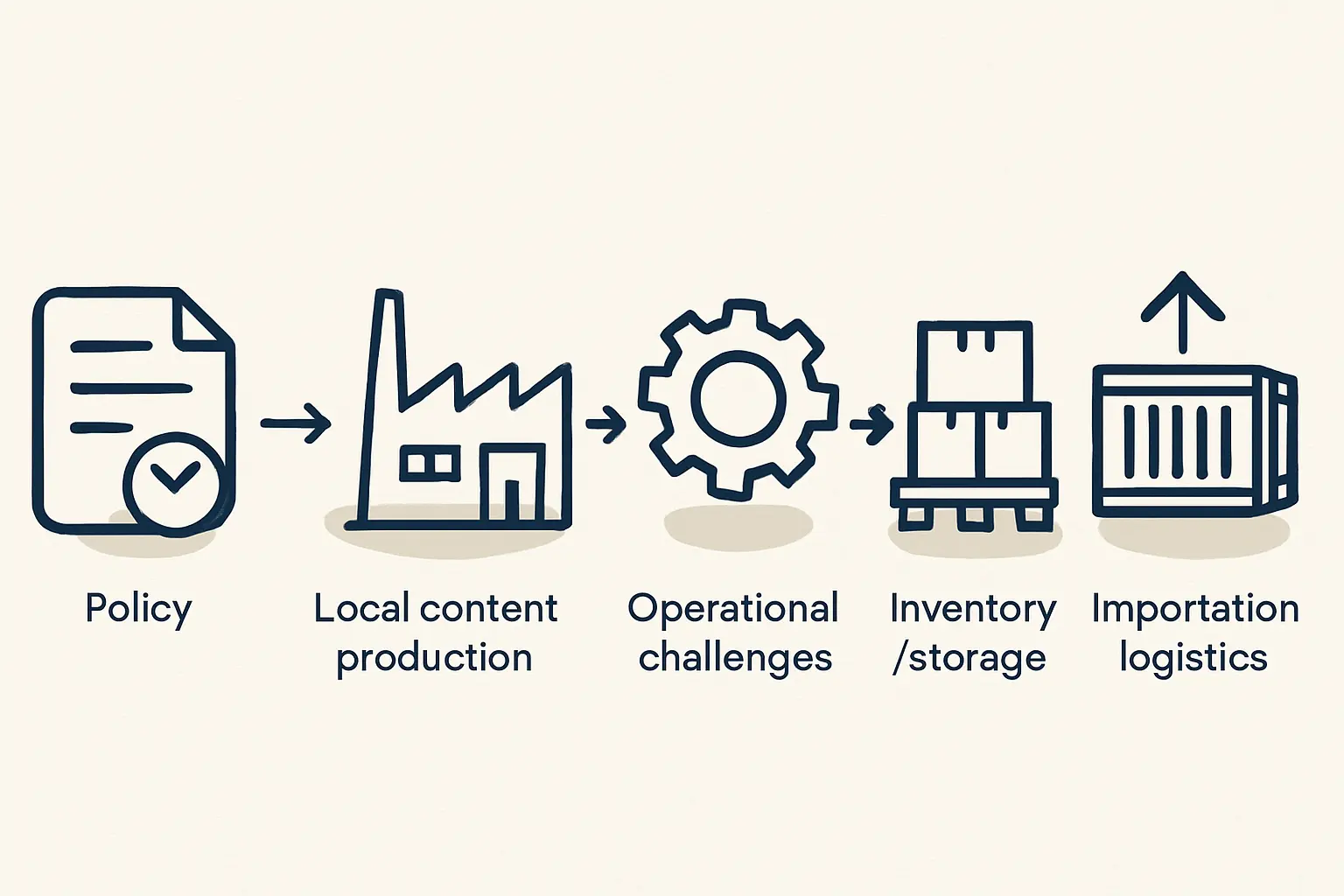

This is more than just a choice between suppliers; it is a fundamental decision that shapes a factory’s cost structure, operational resilience, and eligibility for crucial government incentives. This article examines the strategic trade-offs between local sourcing and importation, providing a clear framework for new investors in Brazil’s solar industry.

Table of Contents

Understanding Brazil’s Solar Manufacturing Landscape

Making an informed supply chain decision starts with understanding the current state of Brazil’s solar industry. While the demand for finished solar panels is high, domestic manufacturing capacity for core components remains limited.

The country’s reliance on international markets is significant: approximately 99% of the solar modules installed in Brazil are imported, primarily from Asia. Local assembly operations exist, but they also depend heavily on imported solar cells.

Foundational elements of the value chain, such as silicon wafers and high-efficiency solar cells, are not yet produced at scale within the country. However, a local ecosystem for other essential components is emerging. Brazilian companies now manufacture key items like aluminum frames, solar glass, junction boxes, and backsheets, creating a dual-market reality that new manufacturers must learn to navigate.

The Case for Importing Components: Opportunities and Hurdles

For many new ventures, importing components is the default starting point. This path offers access to a mature global market with established suppliers, advanced technology, and competitive pricing driven by economies of scale.

The Global Market Advantage

Sourcing from established international suppliers offers several immediate benefits:

- Access to Technology: The global market provides the latest advancements in solar cell efficiency and material science.

- Economies of Scale: Large-scale international producers can often offer lower per-unit costs for critical components like solar cells.

- Established Quality: Top-tier global suppliers have well-documented track records and certifications, reducing initial quality assurance risks.

Navigating Brazil’s “Custo Brasil”

Despite these advantages, importing into Brazil comes with significant challenges, collectively known as “Custo Brasil” (the Brazil Cost). This term encapsulates the operational and financial burdens of doing business in the country, which are particularly pronounced for importers.

Key hurdles include:

- High Import Tariffs: Solar components and finished modules face substantial import duties. The tariff on imported modules is currently 10.8%, and similar taxes apply to individual components, directly increasing the cost of goods.

- Logistical Complexity: Moving goods from a Brazilian port to a factory can be slow and unpredictable. Customs clearance procedures are rigorous, and inland transportation infrastructure can introduce delays.

- Currency Fluctuation: Transactions are typically conducted in U.S. dollars, exposing the business to the volatility of the Brazilian Real (BRL). An unfavorable exchange rate shift can unexpectedly erode profit margins.

A solar panel factory’s business plan must account for these variable, import-related expenses to avoid budget overruns.

The Case for Local Sourcing: Building a Resilient Operation

Opting for local suppliers, where possible, presents a powerful strategic alternative. This approach aligns the business with national industrial policy and can unlock significant long-term advantages.

The Strategic Benefits of “Conteúdo Local”

The Brazilian government actively encourages local sourcing through policies that promote “Conteúdo Local” (Local Content). The most significant of these is the FINAME accreditation from the Brazilian Development Bank (BNDES). Modules with a specified percentage of locally sourced components can become eligible for preferential financing, making them more attractive to large-scale project developers.

Key benefits of local sourcing include:

- Reduced Financial Risk: Sourcing locally minimizes exposure to import tariffs and currency volatility.

- Simplified Logistics: Local sourcing eliminates the complexities of international shipping and customs, leading to shorter, more predictable lead times.

- Access to Incentives: Meeting local content requirements can make the final product eligible for favorable BNDES financing programs, a major competitive advantage.

- Supply Chain Resilience: A local supply chain is less vulnerable to global shipping disruptions or geopolitical events.

The choice of components also dictates the type of solar panel manufacturing equipment required for the production line, as machinery must be calibrated for the specific materials used.

Challenges of the Nascent Local Supply Chain

While the benefits are compelling, Brazil’s local supply chain is still maturing. New manufacturers will face a different set of challenges:

- Limited Component Availability: High-efficiency solar cells, the most critical component, must still be imported.

- Supplier Qualification: Vetting local suppliers for consistent quality, production capacity, and financial stability requires significant due diligence.

- Potential for Higher Costs: For some components, local producers may not yet have the scale to compete on price with global suppliers, though this can be offset by avoiding import duties.

Developing a Hybrid Supply Chain Strategy

For most new solar manufacturers in Brazil, the optimal path is neither complete importation nor exclusive local sourcing. Instead, the most pragmatic and resilient operations rely on a hybrid strategy.

This balanced approach leverages the strengths of both models:

- Import Core Technology: Source high-performance solar cells from leading international manufacturers to ensure the final product’s efficiency and competitiveness.

- Source Bulk Materials Locally: Procure items like aluminum frames, solar glass, junction boxes, and packaging materials from qualified Brazilian suppliers to reduce logistical costs and tariffs.

This hybrid model directly affects the flow and organization of the entire manufacturing process and requires robust inventory management to handle both international and domestic supply streams.

Based on experience from J.v.G. Technology turnkey projects, a phased approach is often most effective. A new factory might begin with a higher percentage of imported components to ensure initial product quality, then gradually integrate and qualify local suppliers over time. This method allows the operation to scale while methodically building a resilient, cost-effective, and locally integrated supply chain.

Frequently Asked Questions (FAQ) for New Manufacturers in Brazil

Q: What is “FINAME accreditation” and why is it important?

A: FINAME accreditation is a certification from the Brazilian Development Bank (BNDES) verifying that a product meets certain local content requirements. Products with this accreditation are eligible for special, often more favorable, financing lines from the bank, making them highly attractive to buyers of utility-scale solar projects.

Q: How significant are import taxes on solar components in Brazil?

A: Import taxes are a major cost factor. Beyond the 10.8% tariff on finished modules, importers must also contend with other taxes like IPI (Tax on Industrialized Products) and PIS/COFINS (social contributions). The cumulative tax burden can significantly increase the final cost of imported goods.

Q: Can I find high-quality solar cells manufactured in Brazil?

A: Currently, the domestic production of high-efficiency solar cells at a commercial scale is negligible. This is the primary bottleneck in the local supply chain, making it necessary for nearly all Brazilian module assemblers to import this critical component.

Q: What are the first steps in finding local suppliers?

A: Good first steps include engaging with Brazilian industry associations like ABSOLAR, attending local energy trade shows, and working with consultants who have an established network of vetted suppliers. Thorough due diligence, including factory audits and quality checks, is essential.

Q: Does a hybrid strategy complicate factory setup?

A: A hybrid strategy requires a more sophisticated supplier management and logistics system than a single-sourcing model. However, the strategic advantages—cost optimization, risk mitigation, and access to incentives—typically outweigh the additional operational complexity.

Conclusion: Your Strategic Path Forward

Entering Brazil’s vibrant solar manufacturing market is a promising venture, but success depends on a well-conceived supply chain strategy. The decision between local sourcing and importation is not binary; it is a nuanced balancing act.

A hybrid approach that imports high-tech core components while leveraging Brazil’s growing ecosystem of material suppliers offers the most resilient and financially sound path forward. This strategy allows a new manufacturer to produce a technologically competitive product while mitigating the risks of “Custo Brasil” and aligning with national industrial objectives.

Navigating these complexities requires detailed financial modeling, rigorous supplier vetting, and a deep understanding of local regulations. A structured business plan, often developed with guidance from experienced industry consultants, is the foundation for building a successful and sustainable solar manufacturing operation in Brazil.