Many entrepreneurs exploring solar manufacturing focus intensely on production technology and machinery. While this is essential, their focus often overshadows a factor that’s equally crucial to success: logistics.

A state-of-the-art factory is useless if raw materials can’t be imported efficiently or finished products can’t be exported competitively. Brunei Darussalam offers a compelling case study—a nation known for its economic stability and strategic location, yet one where any successful solar venture depends entirely on mastering a global supply chain.

This analysis breaks down the practical logistics of establishing a solar module factory in Brunei, from its port infrastructure and the flow of raw materials to viable export routes, laying the groundwork for any serious investor.

Table of Contents

The Strategic Importance of Brunei’s Port Infrastructure

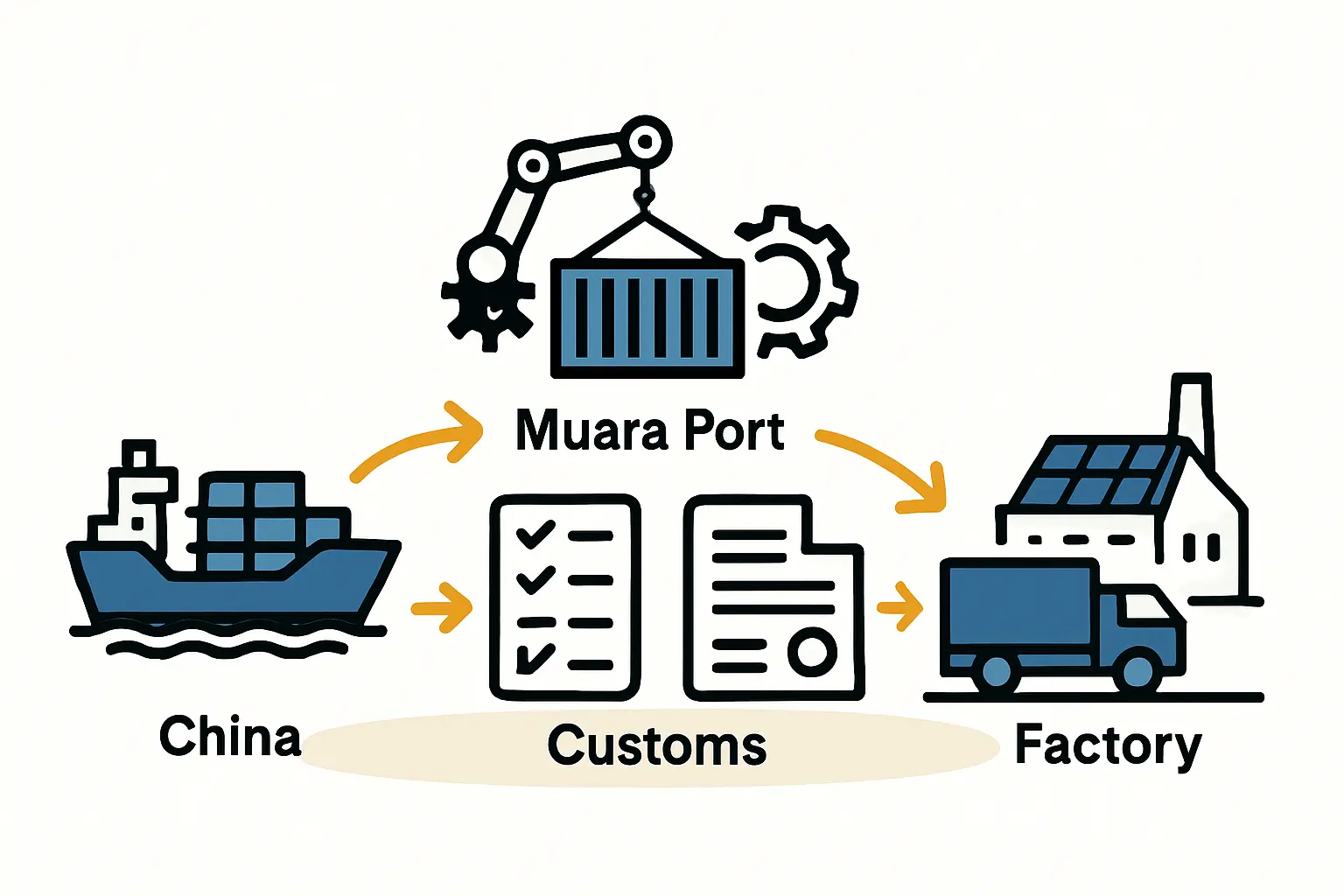

The success of any manufacturing operation in Brunei hinges on its primary maritime gateway: Muara Port. As the country’s main deep-water port, it serves as the logistical heart for both inbound and outbound cargo.

Operated by the Muara Port Company (MPC), a joint venture between Darussalam Assets Sdn Bhd and China’s Beibu Gulf Port Group, the port has seen significant investment in modernization. Key features for a solar module manufacturer include:

- Container Terminal: The port is well-equipped to handle standard 20-foot and 40-foot containers, the primary method for shipping sensitive components like solar cells and glass.

- Connectivity: Muara Port offers shipping connections to major regional hubs, including Singapore, Port Klang (Malaysia), and key ports in Southern China. This network is crucial for establishing reliable supply lines.

- Efficiency: MPC’s operational expertise helps ensure predictable turnaround times for vessels, minimizing inventory costs and avoiding production delays.

A resilient supply chain model starts with understanding Muara Port’s capabilities and limitations. A viable business plan must account for shipping schedules, customs clearance procedures, and inland transportation from the port to the factory site.

Mapping the Inbound Supply Chain: Importing Raw Materials

A solar factory in Brunei faces a fundamental reality: its complete dependence on imported materials. With no domestic manufacturing base for the core components of photovoltaic modules, 100% of the bill of materials must be sourced internationally.

The primary raw materials for solar panels to be imported include:

- Photovoltaic Cells: The most valuable component, typically sourced from major producers in China or Southeast Asia.

- Solar Glass: Specialized, low-iron, tempered glass, usually shipped in dedicated crates within containers.

- Aluminum Frames: Extruded aluminum profiles, precut to size for module assembly.

- Encapsulants and Backsheets: Rolls of EVA (ethylene vinyl acetate) film and polymer backsheets.

- Junction Boxes: Pre-assembled units containing diodes and cables.

The logistical flow involves coordinating with multiple suppliers, primarily in China, consolidating shipments, and managing the maritime journey to Muara. Based on experience from J.v.G. turnkey projects, a typical 40-foot high-cube container can hold enough solar cells for approximately 1 megawatt (MW) of production. This means a successful operator must manage a constant flow of containers to feed the production line.

Outbound Logistics: Exporting Finished Solar Modules

While the import chain is a matter of necessity, the export strategy is where the opportunity lies. Brunei’s strategic location within the ASEAN region, combined with its political stability, makes it an attractive base for exporting to high-growth markets.

Potential target markets for modules manufactured in Brunei include:

- ASEAN Nations: Leveraging the ASEAN Free Trade Area (AFTA) can provide preferential tariff treatment, making Brunei-made modules competitive in markets like the Philippines, Indonesia, and Vietnam.

- Australia: Proximity to the large and mature Australian solar market is a significant advantage, creating a direct and viable export route.

- The Middle East and Africa: Brunei’s well-established trade relationships can facilitate entry into these energy-hungry regions.

To access these markets, finished modules must meet international standards. Obtaining the necessary solar panel certification, such as IEC 61215 and IEC 61730, is a non-negotiable step. The logistics of shipping finished panels—typically stacked vertically on pallets—also requires careful planning to minimize transit damage and cost.

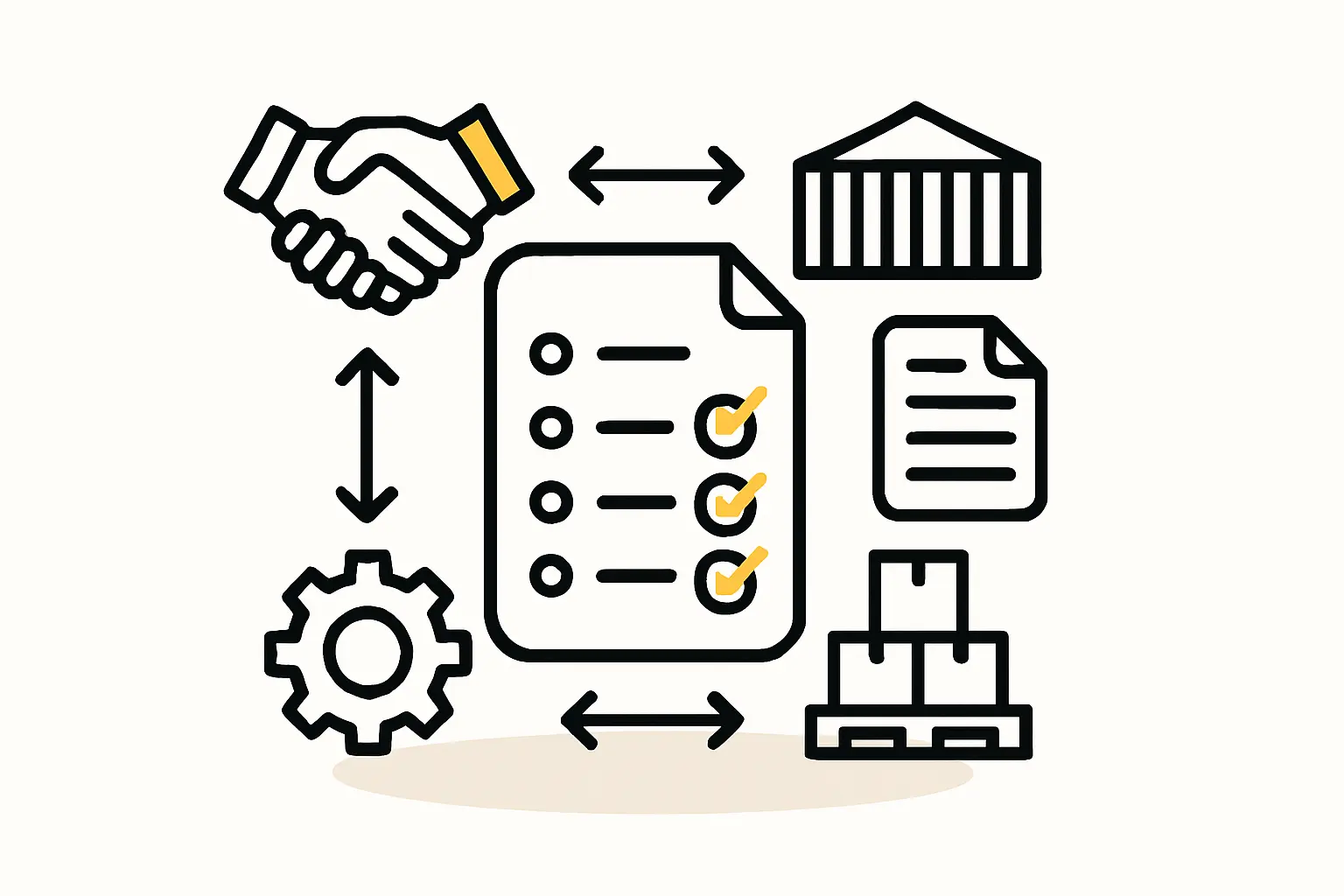

Key Considerations for Investors: A Balanced View

An objective look at Brunei reveals both significant advantages and clear challenges that must be addressed in any viable solar panel manufacturing business plan.

Opportunities

- Political and Economic Stability: Brunei’s stability provides a low-risk environment for long-term capital investment.

- Favorable Tax Regime: Brunei currently has no personal income tax, capital gains tax, or export tax, which can significantly improve project profitability.

- Government Support: The government is actively encouraging economic diversification away from oil and gas, creating a supportive environment for new industries.

Challenges

- Total Import Reliance: The entire supply chain is exposed to global shipping disruptions and price volatility.

- Labor Market: Higher labor costs compared to regional manufacturing hubs and a reliance on foreign technical expertise require careful workforce planning.

- Scale and Local Market: Brunei’s domestic market is small, meaning the business model must be almost entirely export-oriented from day one.

These factors underscore that success requires meticulous planning. A successful venture isn’t just about manufacturing a product; it’s about orchestrating a complex international logistics operation from a stable and strategic base.

Frequently Asked Questions (FAQ)

Q: Why consider Brunei for solar manufacturing?

A: Brunei offers a unique combination of political stability, a highly favorable tax environment with no export taxes, and a strategic maritime location to serve the ASEAN region and Australia. This makes it an ideal base for an export-focused business model.

Q: Are there any local suppliers for solar panel components in Brunei?

A: No. All core technical components—from solar cells and glass to aluminum frames and junction boxes—must be imported. A manufacturer might source ancillary materials like packaging locally, but the primary bill of materials is 100% reliant on imports.

Q: What are the primary shipping routes for imports?

A: The most critical supply lines originate from major industrial ports in China (e.g., Shanghai, Ningbo, Qingdao) and regional hubs like Port Klang in Malaysia and the Port of Singapore, all connecting to Brunei’s Muara Port.

Q: Which export markets offer the most potential for modules made in Brunei?

A: The ASEAN member states are the most immediate and logical market, benefiting from the AFTA trade agreement. Australia represents a large, nearby market for high-quality modules. The Middle East and select African nations are also viable secondary markets.

Next Steps in Your Project Analysis

Understanding Brunei’s logistical landscape is a critical first step. It reveals that the core challenge isn’t simply building a factory, but designing and managing a resilient and cost-effective international supply chain. Success depends on a holistic plan that integrates procurement, shipping, production, and export into a seamless operation.

For entrepreneurs ready to evaluate this venture, the next step is a detailed feasibility study. This study must quantify shipping costs, identify reliable suppliers, and model the complete financial picture of an export-oriented solar manufacturing business in Brunei.