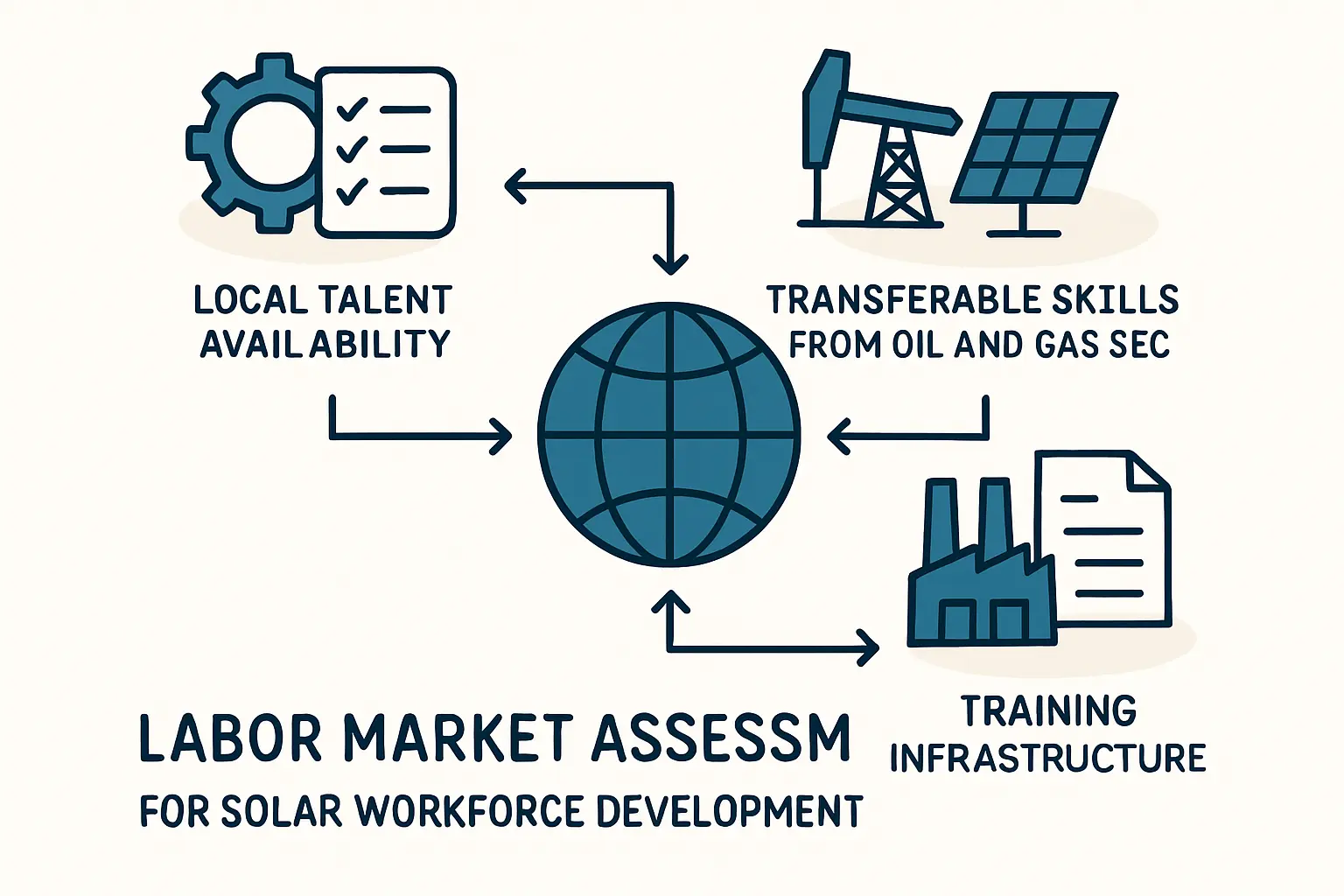

When an entrepreneur considers entering the solar module manufacturing sector, the focus often falls on machinery, technology, and financing. However, a venture’s long-term success ultimately depends on its most critical asset: its people. In a specialized market like Brunei, with its unique economic landscape, knowing how to source, train, and retain a skilled team is not just an operational task—it is a strategic imperative.

This analysis explores the key considerations for building a competent workforce for a solar module factory in Brunei, addressing local talent availability, essential training programs, and the strategic role of international expertise.

Table of Contents

Understanding Brunei’s Current Labor Landscape

Brunei’s economy is in transition. Historically reliant on its substantial oil and gas reserves, the nation is actively pursuing economic diversification under its Wawasan Brunei 2035 development plan. This national vision aims to cultivate a dynamic and sustainable economy, creating opportunities for new industries like renewable energy manufacturing.

For a prospective solar factory owner, this context presents both opportunities and challenges:

- Educated but Inexperienced Workforce: While Brunei boasts a high literacy rate and a strong education system, its labor market has traditionally been dominated by the public sector and the oil and gas industry. Experience in high-tech, precision manufacturing—such as solar PV production—remains limited.

- Government Support for Upskilling: In line with Wawasan 2035, government bodies and educational institutions are increasingly focused on developing vocational and technical skills relevant to new industries, creating opportunities for collaboration on training initiatives.

- A Small Talent Pool: As a small nation, the overall pool of available labor is limited. This makes effective recruitment and employee retention especially important.

Successfully navigating this environment requires a proactive approach to human resources, starting with a clear understanding of the specific roles needed to operate a solar module production line.

Identifying Key Roles for a Solar Module Production Line

A semi-automated solar module factory, with a typical annual capacity of 20–50 MW, can be operated efficiently with a team of 25 to 40 employees per shift. These roles fall into four main categories, each requiring a different skill set and training approach.

Machine Operators

These individuals form the core of the production team, handling the daily operation of key equipment like the stringer, laminator, and framer. Ideal candidates are detail-oriented, reliable, and able to follow standardized processes with precision. A technical diploma or vocational school background is beneficial but not always required.

Technicians

Technicians are responsible for machine setup, calibration, routine maintenance, and troubleshooting. This role demands strong mechanical and electrical aptitude. Candidates with experience in industrial maintenance or from vocational programs in mechatronics or electronics are well-suited for these positions.

Engineers and Quality Control Staff

This group oversees the entire production process, ensuring efficiency and adherence to quality standards like ISO 9001. Responsibilities include process optimization, material flow management, and final product inspection using tools like sun simulators and EL testers. A university degree in electrical, mechanical, or industrial engineering is the standard requirement.

Management and Administration

This includes the plant manager, supply chain personnel, and administrative staff who manage overall business operations. For these roles, business acumen and leadership experience are as crucial as technical understanding. The necessary leadership structure is often defined during the factory’s initial planning phase.

The “Build vs. Buy” Decision: Training Local Talent vs. Hiring Expatriates

One of the first strategic decisions a new factory owner in Brunei will face is how to balance developing local talent with the need for immediate expertise. Based on experience from J.v.G. turnkey projects, a hybrid approach is usually the most effective and sustainable model.

The Case for Developing a Local Team

Investing in the training of Bruneian nationals offers significant long-term advantages. It builds a sustainable operational base, demonstrates commitment to the local economy, and can foster strong employee loyalty. Partnering with local institutions like the Institute of Brunei Technical Education (IBTE) can help create a pipeline of candidates with foundational skills who can then be trained on specific solar manufacturing processes.

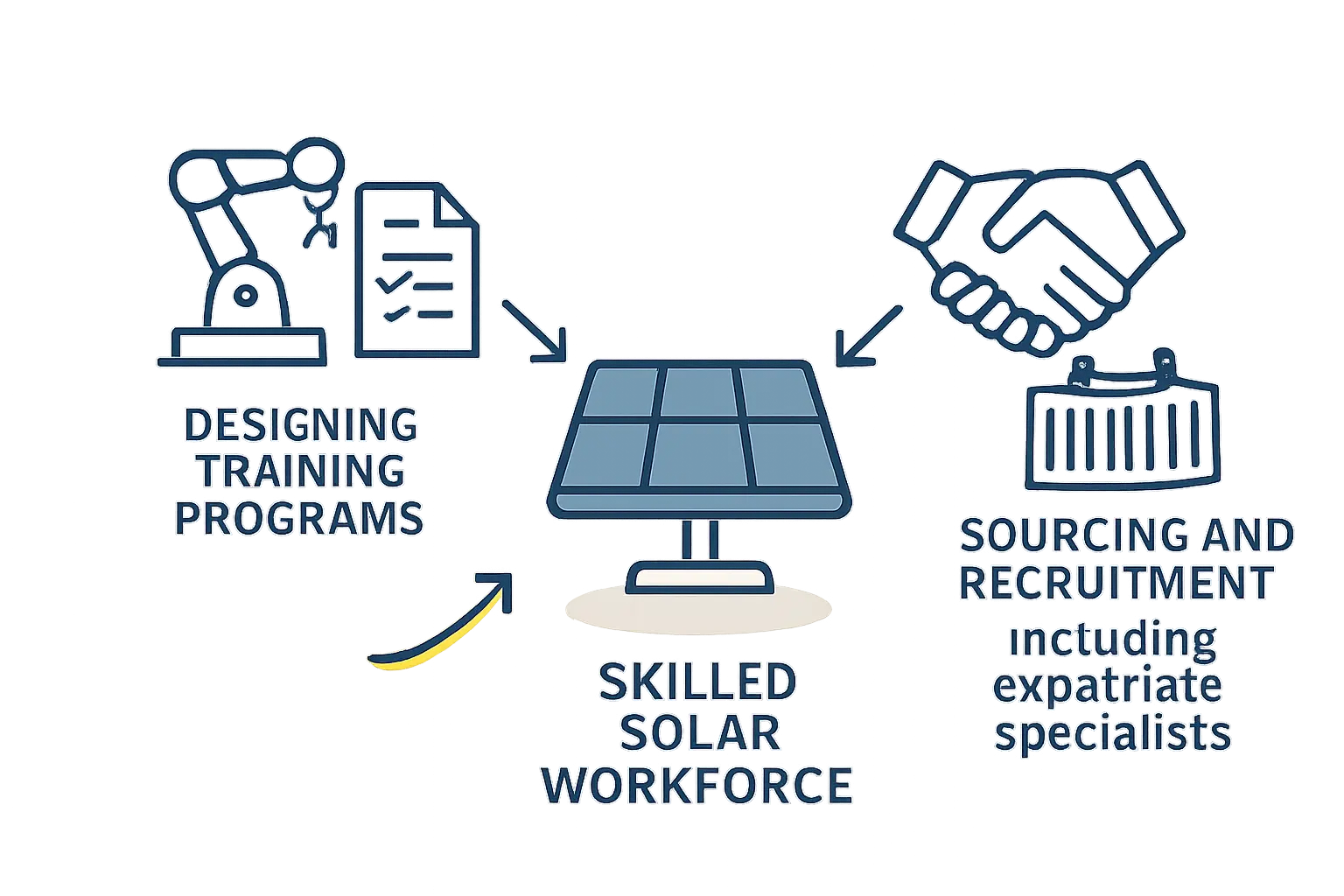

The Strategic Use of Expatriate Expertise

In the initial phase, a completely local team is unlikely to have the specialized knowledge required to set up and ramp up a solar module factory. Expatriate specialists—typically a plant manager, a lead process engineer, or a senior technician—play a critical role for the first 12 to 24 months.

Their primary functions are:

- Commissioning: Overseeing the installation and commissioning of the production line.

- Knowledge Transfer: Implementing best practices and establishing standard operating procedures (SOPs).

- Training the Trainers: Developing the skills of local engineers and lead technicians, who will then be responsible for training the operators.

This model ensures a smooth start-up while building the long-term capabilities of the local workforce.

Developing a Comprehensive Training Program

A structured training program is essential for developing a new team’s capabilities. This program should blend theoretical knowledge with practical, hands-on skills.

1. Foundational Onboarding

All new hires should undergo an induction program covering factory safety protocols, quality principles, and a basic introduction to photovoltaic technology. This ensures everyone shares a common understanding of the company’s goals and standards.

2. Supplier-Led Machine Training

The suppliers of core production equipment, such as the automated solar cell stringer machine, typically provide intensive, hands-on training as part of the commissioning process. This is the most critical training component for operators and technicians, as they learn directly from the equipment experts.

3. Process and Quality Control Training

Engineers and quality managers need training on the entire production workflow, from incoming material inspection to final module testing. This training, often led by an experienced consultant or an expatriate lead engineer, focuses on maximizing yield, minimizing defects, and maintaining consistent output. Guidance on ideal factory building requirements during the planning phase can facilitate a smoother workflow design.

Frequently Asked Questions (FAQ)

Q: How many employees are needed for a small-scale solar factory in Brunei?

A: A semi-automated line with an annual capacity of 20–50 MW typically requires a workforce of 25 to 40 people per shift. This includes operators, technicians, quality control staff, and management.

Q: What is the minimum educational background for a machine operator?

A: While a technical or vocational certificate is an advantage, a secondary school education is often sufficient for operator roles, provided the candidate demonstrates strong attention to detail and a capacity to learn. The most important training will be hands-on at the factory.

Q: How long does it take to train a new production team?

A: A new team can typically be trained to operate a production line within three to six months. This timeline includes initial onboarding, machine-specific training by suppliers during installation, and a period of supervised production to reach full capacity and quality standards.

Q: Can a solar factory in Brunei be run entirely with local staff from the beginning?

A: While the long-term goal is a fully local team, it is highly advisable to employ one to three expatriate specialists for the initial 12 to 24 months. Their experience is invaluable for ensuring a smooth and efficient setup, establishing international quality standards, and accelerating the local management team’s development.

Q: What is the biggest HR challenge to anticipate

A: Beyond finding candidates with direct experience, the primary challenge is often instilling the culture of precision and quality control that is paramount in electronics manufacturing. This requires continuous reinforcement from management and a commitment to ongoing training.

Conclusion:

While Brunei’s labor market presents a unique set of variables, building a skilled and motivated workforce for a solar module factory is an achievable goal. It requires a strategic blend of local talent development, targeted international expertise, and a robust, well-structured training program. With careful planning, a new manufacturing venture can become a source of valuable employment and a key contributor to Brunei’s economic diversification goals.