It’s a stark paradox: a factory designed to produce the very technology that generates electricity can itself be brought to a standstill by a power outage. For entrepreneurs planning to enter the solar manufacturing space, particularly in regions with developing infrastructure, this isn’t just a hypothetical scenario. It’s a critical business risk that can mean the difference between profitability and failure.

A reliable power supply is fundamental to any manufacturing operation. For the precise and sensitive equipment used in solar module production, however, an inconsistent energy source is more than an inconvenience—it’s a direct threat to production quotas, product quality, and financial viability.

This article breaks down the operational necessity and financial logic behind integrating a dedicated solar-plus-storage system to ensure your factory remains productive, even when the public grid fails.

Table of Contents

The High Cost of an Unstable Grid for Manufacturing

In many emerging markets, from Africa to the Middle East, national grids often suffer from frequent interruptions. While a typical business might lose a few hours of work, the consequences for a solar module factory are far more severe.

Research from projects in regions like N’Djamena, Chad, shows that daily grid outages can last anywhere from one to six hours. This level of unreliability creates several layers of cost and risk:

- Production Downtime: The most immediate cost is lost output. Every hour the production line stands idle represents a direct loss of revenue.

- Material Waste: An abrupt power loss during sensitive processes like lamination or cell stringing can damage materials and render partially completed modules useless. This waste directly impacts the cost of goods sold.

- Equipment Damage: Sudden power surges or cuts can damage the sophisticated automation and control systems in modern solar panel manufacturing machines. Repairing or replacing this equipment is both costly and time-consuming.

- Increased Labor Costs: Restarting production lines after an outage requires time and manpower, reducing overall labor efficiency and increasing operational expenses.

Relying solely on diesel generators as a backup, while common, presents its own set of challenges, including high fuel costs, price volatility, and significant maintenance requirements.

The Strategic Solution: A Captive Solar-Plus-Storage System

To counteract grid unreliability, a growing number of industrial operators are turning to captive power plants. A captive power system is an electricity generation facility dedicated to providing a stable power supply for a specific entity, such as a factory, independent of the national grid.

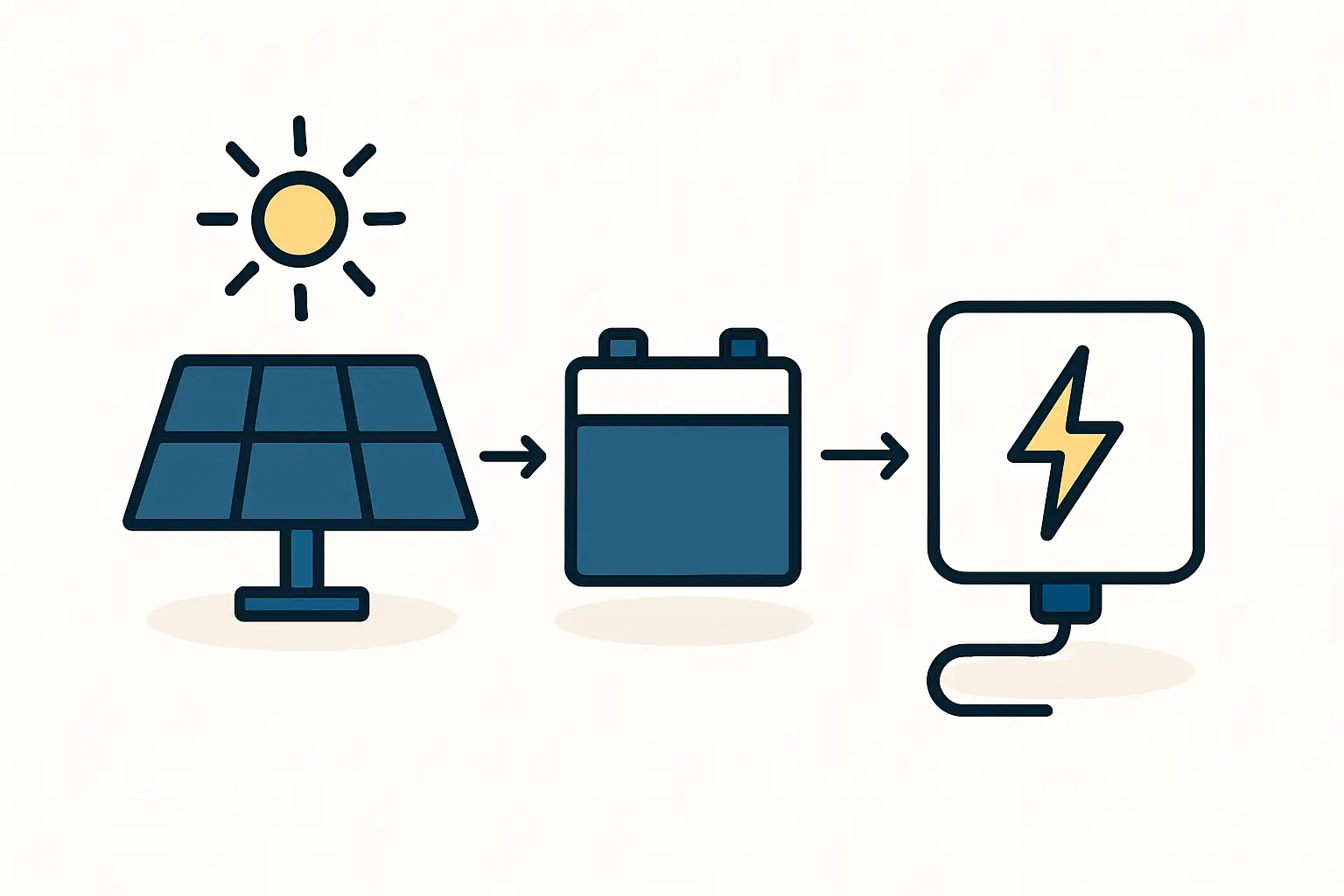

For a solar module factory, the most logical and financially sound captive solution is a solar-plus-storage system. This setup typically consists of:

- A Solar PV Array: Sized to meet the factory’s daytime energy demands and to charge the batteries.

- A Battery Energy Storage System (BESS): Stores excess solar energy generated during the day and discharges it to power the factory during grid outages, at night, or during periods of peak demand.

- An Intelligent Power Management System: Acting as the brain of the operation, this system seamlessly switches between grid, solar, and battery power to ensure the production line receives an uninterrupted, high-quality electricity supply.

This integrated system effectively creates a private microgrid for the factory, insulating it from external power disruptions.

A Case Study: Ensuring Operational Continuity in N’Djamena, Chad

To see this in practice, consider an entrepreneur planning a 50 MW solar module factory in a location like N’Djamena. The local grid is known for its instability, and the cost of grid electricity is approximately $0.25 per kilowatt-hour (kWh), while the default backup—diesel generation—is even more expensive at around $0.40/kWh.

Drawing on its experience with turnkey projects, J.v.G. Technology GmbH designed a resilient power solution to ensure 24/7 operation. The system included:

- A 1 Megawatt (MW) solar PV array installed on the factory rooftop and adjacent land.

- A 2 Megawatt-hour (MWh) Battery Energy Storage System (BESS).

This configuration allows the factory to run primarily on self-generated solar power during the day. The BESS is charged with surplus solar energy and provides consistent power during frequent grid outages, ensuring the lamination, stringing, and testing machines never stop.

The Financial Case: From Operational Expense to Strategic Investment

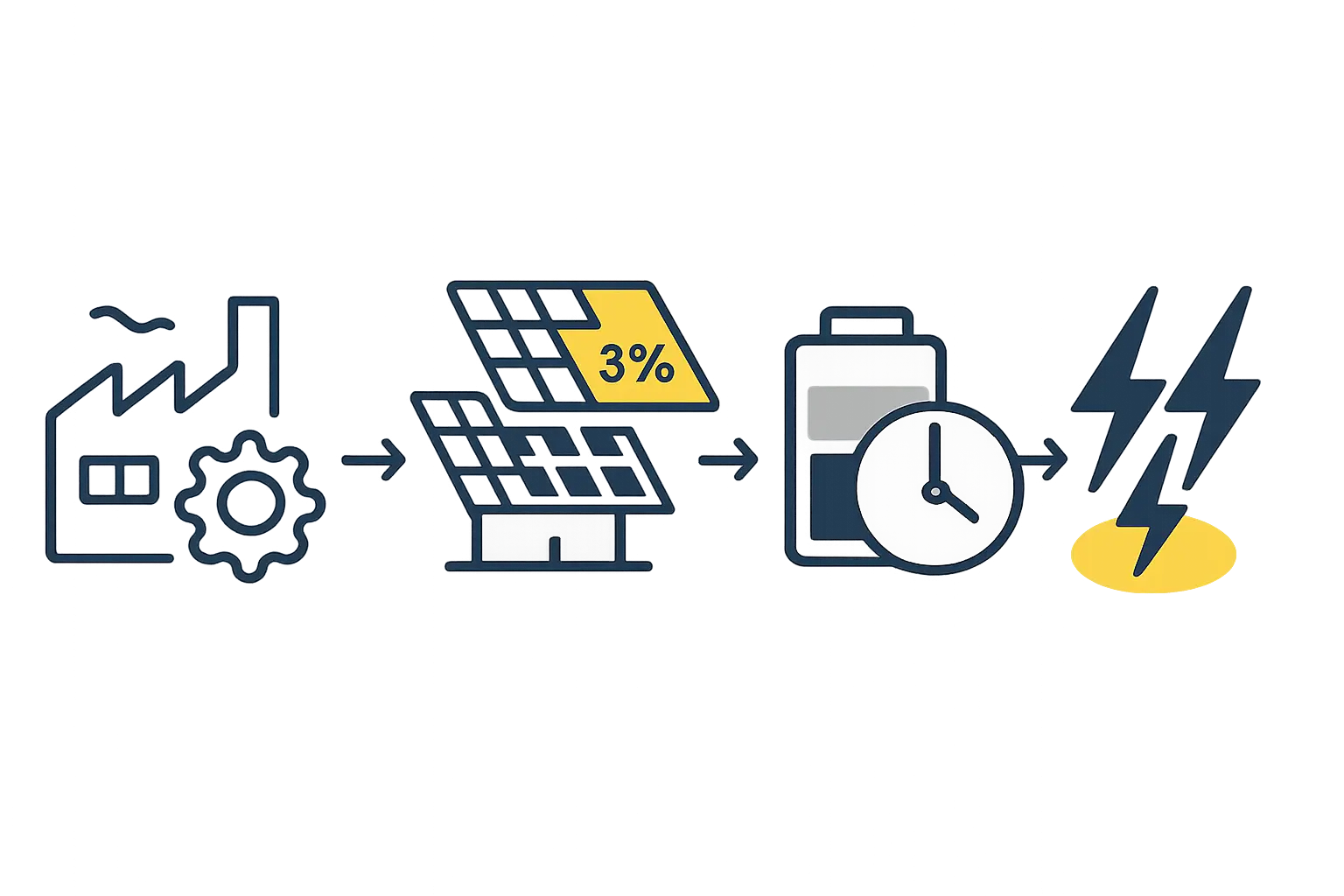

At first glance, the upfront cost of a 1 MW solar array and a 2 MWh battery system may seem substantial. However, a closer look at the Levelized Cost of Energy (LCOE)—the average cost to produce electricity over the system’s lifetime—reveals a compelling financial argument.

The LCOE for this captive solar-plus-storage system is calculated to be approximately $0.15/kWh.

Here’s how that compares with the alternatives:

- Captive Solar + Storage: ~$0.15/kWh.

- Grid Electricity: ~$0.25/kWh.

- Diesel Generator: ~$0.40/kWh.

Self-generation, therefore, is not just more reliable—it’s also significantly cheaper than both grid and diesel power. This investment transforms energy from a volatile operational expense into a predictable, low-cost asset.

With these savings, the payback period for such a system is typically between 4 to 6 years. Over its 25-year lifespan, the system generates substantial long-term savings, improving the factory’s overall profitability and competitiveness. This makes the system a critical part of any sound business plan for a solar panel factory.

Key Design Considerations for Your Factory’s Power System

Integrating a captive power system requires careful planning and should ideally be part of the factory’s initial design, influencing the overall layout. Key factors to consider include:

- Load Profiling: A detailed analysis of the factory’s minute-by-minute energy consumption is essential for accurately sizing the PV array and battery system.

- System Sizing: The system must be large enough to handle peak production loads while also having the capacity to charge the batteries for overnight or outage coverage.

- Integration: The system must be engineered to work seamlessly with the local grid (if a connection is maintained as a backup) and any existing diesel generators.

- Scalability: The design should allow for future expansion as the factory’s production capacity grows.

Frequently Asked Questions (FAQ)

Q: What is a captive power plant?

A: A captive power plant is a private electricity generation facility used by an industrial or commercial entity for its own energy consumption. It provides energy independence and reliability, separate from the public grid.

Q: Is a solar-plus-storage system sufficient on its own?

A: For most industrial applications in regions with unstable grids, a solar-plus-storage system is designed to handle the majority of the factory’s needs. The grid connection or a smaller backup diesel generator is often kept as a tertiary safety net for prolonged periods of bad weather or system maintenance.

Q: How does this affect the initial investment cost?

A: Integrating a captive power system increases the initial capital expenditure. However, as the financial analysis shows, it significantly reduces long-term operational costs, protects against production losses, and typically offers a strong return on investment with a payback period of under six years.

Q: Can the system sell excess power back to the grid?

A: In some jurisdictions with supportive regulations (like net metering or feed-in tariffs), it may be possible to sell surplus electricity back to the utility. This can create an additional revenue stream and further improve the project’s financial returns. However, this possibility depends entirely on local energy policy.

Planning Your Path to Energy Independence

For any entrepreneur exploring how to start a solar panel factory, securing a reliable and cost-effective power supply is not an ancillary detail—it is a core strategic requirement. An unstable grid poses a direct threat to the business’s operational and financial health.

By designing a captive solar-plus-storage system from the outset, you aren’t just buying equipment; you are investing in operational certainty, cost control, and long-term resilience. This foundational step ensures that your factory can produce efficiently and profitably, fully insulated from the unreliability of the external grid.