An entrepreneur planning to establish a solar module factory in a market like Chad often secures the financing, technology, and location, only to face a critical question: Who will operate the machinery?

While many emerging economies boast a large, youthful labor pool, they often face a shortage of technicians with specialized experience. But far from being an obstacle, this gap represents a significant opportunity to build a loyal, highly capable workforce from the ground up.

The demographic reality of Sub-Saharan Africa, where the median age is just 19.7 and 60% of the population is under 25, presents a vast reservoir of human potential. However, a systemic gap in vocational and technical education leaves this potential largely untapped. The solution lies not in searching for non-existent experience, but in creating it. An effective solar manufacturing operation must double as a world-class training center, transforming motivated local individuals into proficient technicians.

Table of Contents

The Foundation: Shifting from Experience-Based to Aptitude-Based Recruitment

In developed manufacturing economies, recruitment often prioritizes candidates with years of relevant experience. This model is impractical in markets where the solar industry is nascent. The focus must shift from what a candidate has already done to what they are capable of learning.

A successful recruitment strategy for a new solar factory prioritizes attributes like:

- Attention to Detail: The ability to handle delicate components like solar cells and follow precise assembly steps is crucial.

- Manual Dexterity: Assembling modules requires steady hands and a high degree of coordination.

- Problem-Solving Aptitude: Technicians should be able to identify minor deviations in the process and flag them appropriately.

- Commitment to Learning: A positive attitude and a genuine desire to acquire new technical skills are the most valuable assets.

This approach significantly widens the pool of potential candidates and builds a company culture centered on growth and internal development—a powerful tool for fostering long-term employee retention. For entrepreneurs looking at how to start a solar panel factory, planning for this human capital development is as critical as sourcing the machinery.

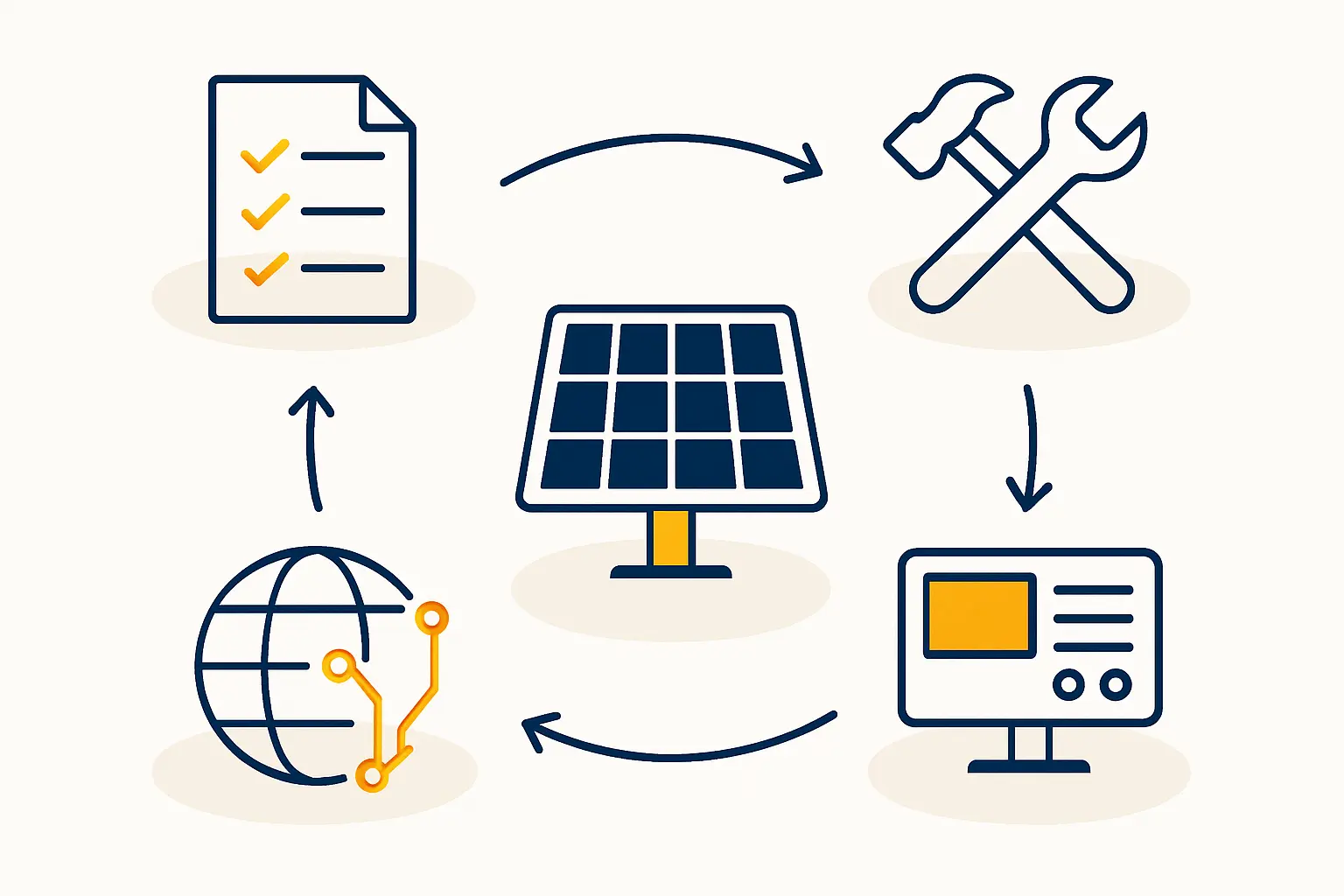

A Three-Phase Curriculum for Technical Proficiency

A structured, intensive training program offers the most efficient path to building a competent production team. This curriculum should be highly practical and visual, minimizing reliance on dense written materials—a particularly important consideration in regions with lower literacy rates, such as Chad, where it stands at approximately 22%.

Drawing on experience from J.v.G. turnkey projects, a 12-week framework offers a robust foundation for new technicians.

Phase 1: Foundation & Safety (Weeks 1-4)

This initial phase instills the fundamental principles and professional habits required for a high-tech manufacturing environment.

- Workplace Safety: Comprehensive training on electrical safety, materials handling, and emergency procedures.

- Cleanroom Protocol: Understanding the importance of a contaminant-free environment and learning proper gowning and conduct.

- Basic Technical Concepts: An introduction to solar energy principles, the function of a PV module, and its core components.

- Tool Handling & Metrology: Proper use and care of essential tools and basic measurement instruments.

Phase 2: Core Process Specialization (Weeks 5-10)

During this phase, trainees rotate systematically through each key station of the assembly line. This hands-on approach ensures every team member understands the complete solar panel manufacturing process, even if they later specialize in one area.

Key stations include:

- Cell Stringing: Learning to connect individual solar cells into strings with precision.

- Lay-Up: Assembling the module layers (glass, EVA, cell matrix, backsheet) in the correct sequence.

- Lamination: Operating the laminator, a critical piece of equipment that encapsulates the module.

- Framing and Junction Box Installation: Fitting the aluminum frame and attaching the junction box, which houses the electrical connections.

This stage is typically overseen by experienced engineers who provide direct instruction and supervision, ensuring trainees learn the correct techniques from the outset.

Phase 3: Operational Integration & Quality Control (Weeks 11-12)

In the final phase, the focus shifts from individual tasks to integrated team performance.

- Line Simulation: The team works together to assemble complete modules under supervision, focusing on workflow, communication, and efficiency.

- Introduction to Quality: Trainees learn the fundamentals of solar panel quality control, including visual inspection criteria and the use of testing equipment like sun simulators and EL testers.

- Role Identification: By this stage, the natural aptitudes of individual technicians become clear, allowing for initial assignments to specialized roles and the identification of potential team leaders.

Case Insight: A Practical Application in Chad

The value of this framework is best demonstrated by its practical results. In a project in Chad, J.v.G. Technology GmbH implemented this intensive model to staff a new turnkey solar manufacturing line.

A team of 28 local personnel, none of whom had prior experience in solar manufacturing, was recruited based on aptitude. Through a focused three-month program led by German engineers, the team achieved full operational readiness. This experience demonstrates that a structured approach can successfully build a highly skilled local workforce capable of producing high-quality solar modules, even in a region without a pre-existing industrial base.

Long-Term Success: Retention and Career Development

Training a skilled workforce is a significant investment. Protecting that investment requires a clear strategy for employee retention. In environments where skilled labor is scarce, a well-trained technician becomes an invaluable asset.

Key retention factors include:

- Competitive Compensation: Offering wages and benefits that are competitive within the local industrial market.

- Clear Career Paths: Establishing opportunities for advancement from technician to line supervisor, quality inspector, or maintenance specialist.

- Continuous Improvement: Creating a work environment that values employee input and encourages ongoing skill development.

- Positive Work Culture: Building a culture of respect, safety, and teamwork.

By investing in their people, companies not only ensure operational stability but also establish themselves as a premier employer in the region, attracting and retaining the best local talent.

Frequently Asked Questions (FAQ)

Q: What is the ideal educational background for a trainee?

A: A basic secondary education is beneficial, but the most important requirements are aptitude, a willingness to learn, and good manual dexterity. The training program is designed to build technical knowledge from the ground up.

Q: How is training adapted for low-literacy environments?

A: The program emphasizes hands-on demonstration, visual aids, and repetition. Instructions are given verbally and through practice rather than relying on written manuals. Key safety information is communicated through universally understood symbols.

Q: What is the role of expatriate experts in the long term?

A: Initially, expatriate engineers or master trainers are essential for leading the training and establishing operational standards. Their primary goal, however, is knowledge transfer. A successful program includes a “train-the-trainer” component to develop local supervisors who can onboard future employees.

Q: How does workforce development impact the overall business plan?

A: Workforce training should be a dedicated line item in the initial investment and operational budget. The timeline for how to start a solar panel factory must account for the three- to four-month period required for recruitment and initial training before full-scale production can begin.

Q: Can this model be applied in other regions?

A: Yes, this framework of aptitude-based recruitment and structured, hands-on training is highly adaptable. It has proven effective in various markets across Africa, the Middle East, and Latin America where a local base of experienced solar technicians does not yet exist.

Conclusion: Building Local Expertise as a Competitive Advantage

The challenge of finding a skilled workforce in emerging markets is not a barrier—it’s a call to adopt a more strategic approach to human capital. By viewing the factory as both a production facility and an educational institution, an entrepreneur can build a formidable competitive advantage.

A well-trained, motivated local team is more cost-effective, more stable, and more invested in the long-term success of the enterprise than a rotating cast of external experts. This investment in people yields returns not only in operational efficiency and product quality but also in creating sustainable economic value for the local community.